Colorless petroleum marker dyes

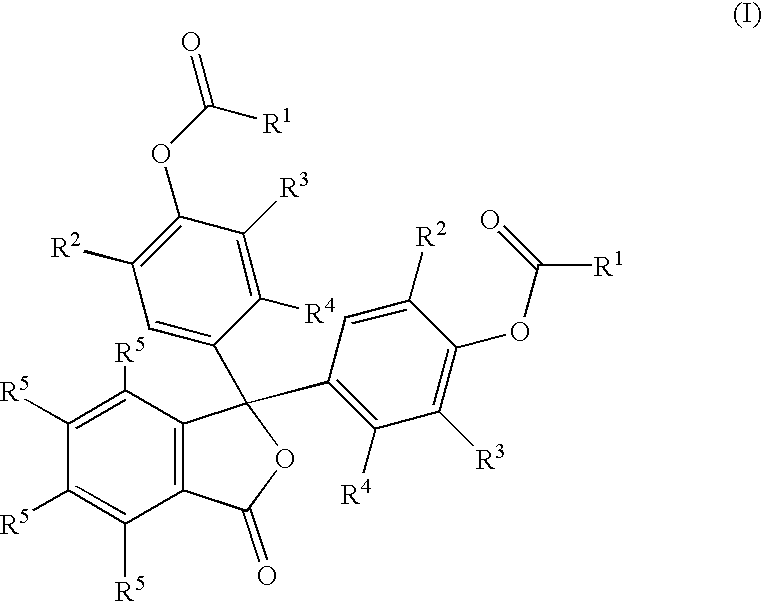

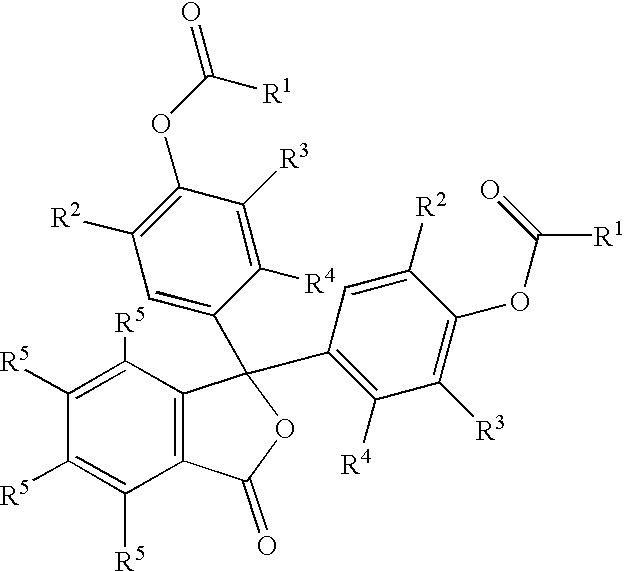

a petroleum marker and dye technology, applied in the direction of diaryl/triaryl methane dyes, thickeners, fuels, etc., can solve the problems of phthalein derivatives and their typically low solubility in petroleum products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

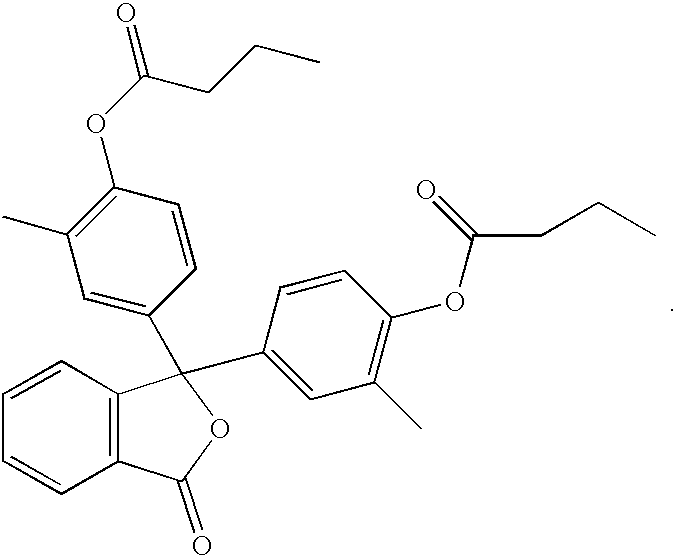

example 1

Preparation of the Di-n-Butyl Ester of o-Cresolphthalein

[0013] To a 100 mL, three-neck round-bottom flask fitted with a stirrer, thermocouple and a condenser, the following raw materials were added: (1) o-cresolphthalein, 1.73 g (0.005 moles); (2) water, 30 mL; (3) 50% NaOH, 0.8 g; (4) Na.sub.2CO.sub.3, 0.6 g; and (5) xylenes, 8 g. The mixture was stirred at 20-25.degree. C. for one hour, during which butyric anhydride, 2 g, was added. The mixture was then heated to 50-55.degree. C. until TLC revealed that the esterification reaction was complete. The upper xylenes layer was separated and 1-octyl-2-pyrrolidone, 2.5 g was added to it. Xylenes and water were removed azeotropically under vacuum. A residue of 6.6 g was obtained.

[0014] A marker solution was prepared by dissolving a 100 mg portion of the residue in xylenes (100 mL), and diluting 1 mL of the resulting solution to 100 mL with kerosene to make a 10 ppm solution.

[0015] A developer was made by dissolving 1 g of a 40% solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com