Method for preparing hydrogen-rich fuel gas through rapid co-pyrolysis of dewatered Fenton sludge and biomass

A biomass and co-pyrolysis technology, which is applied in the fields of biofuels, production of combustible gases, chemical instruments and methods, etc., can solve the problems of large output of dewatered Fenton sludge and high treatment costs, and achieve the promotion of in-situ catalytic cracking and product energy. The effect of high density and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

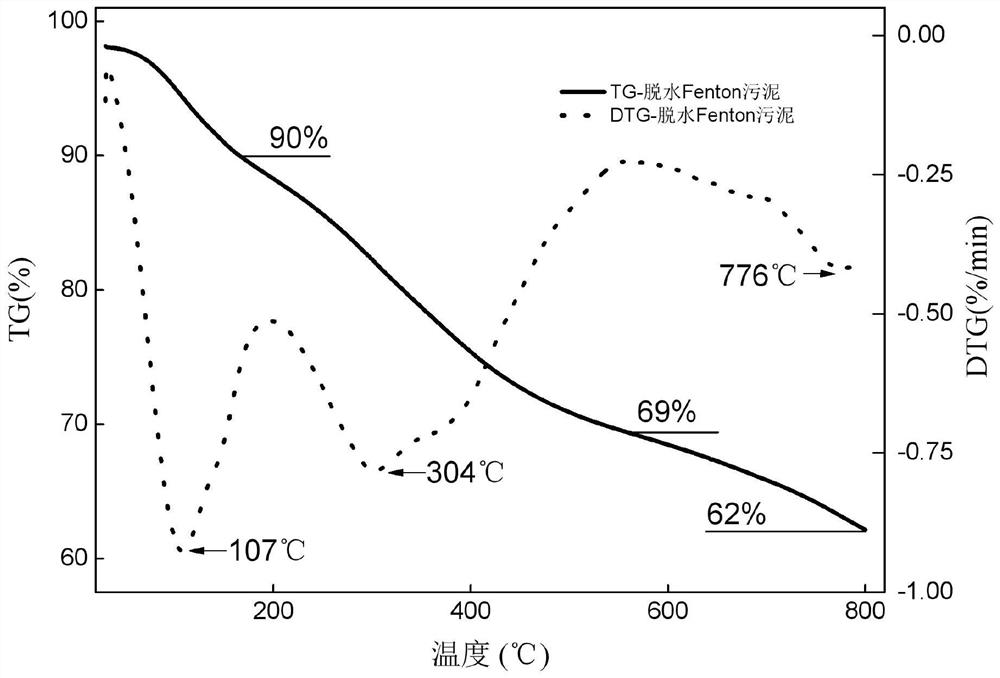

[0043] Fenton sludge is dehydrated (Fenton sludge is from Hangzhou Guotai Environmental Protection Technology Co., Ltd.), and the treatment process is as follows: Fenton sludge is firstly dehydrated by mechanical pressure filtration, and then dried at 105°C for 12 hours to obtain dehydrated Fenton sludge. mud.

[0044] In order to explore the specific composition of dewatered Fenton sludge, X-ray fluorescence spectroscopic analysis was performed on dewatered Fenton sludge to explore the content of inorganic components. The test results are shown in Table 1.

[0045] Table 1 XRF analysis of dewatered Fenton sludge

[0046]

[0047] It can be obtained from Table 1 that the Fe in dehydrated Fenton sludge 2 o 3 The content is as high as 89.64%. Iron and iron oxides have very good catalytic activity for tar reforming and cracking reactions. Therefore, dehydrated Fenton sludge can act as an iron-based catalyst in the process of biomass pyrolysis. In addition, the CaO component...

Embodiment 2

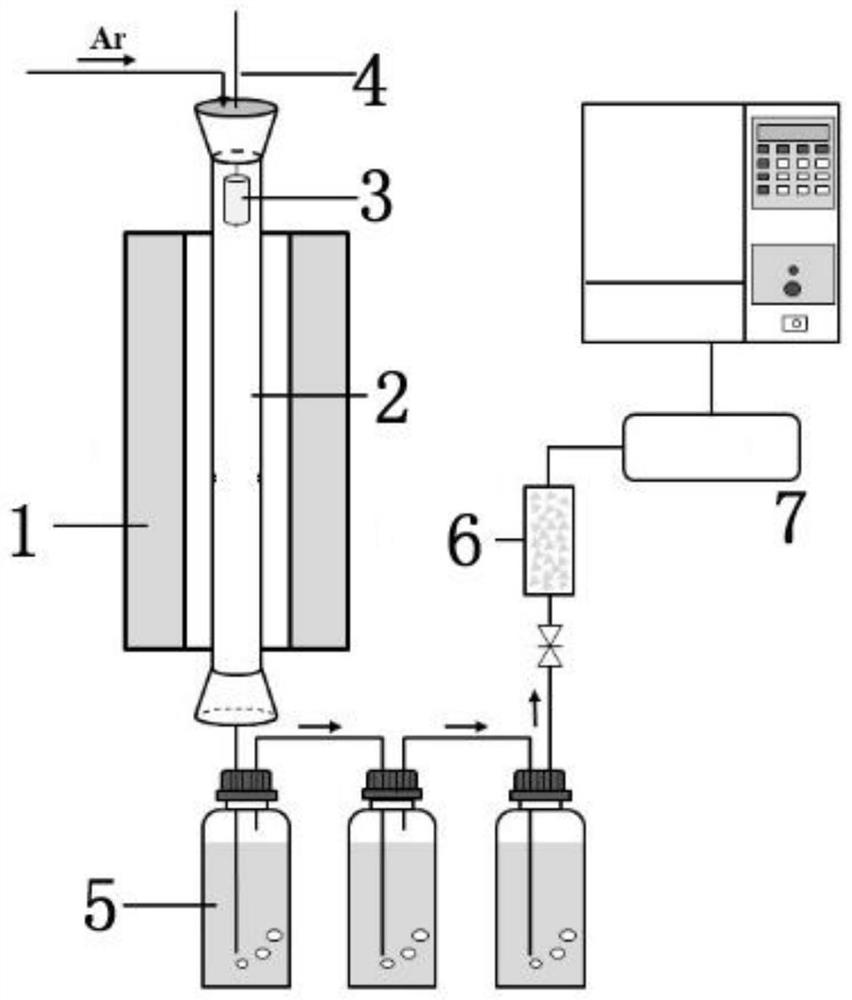

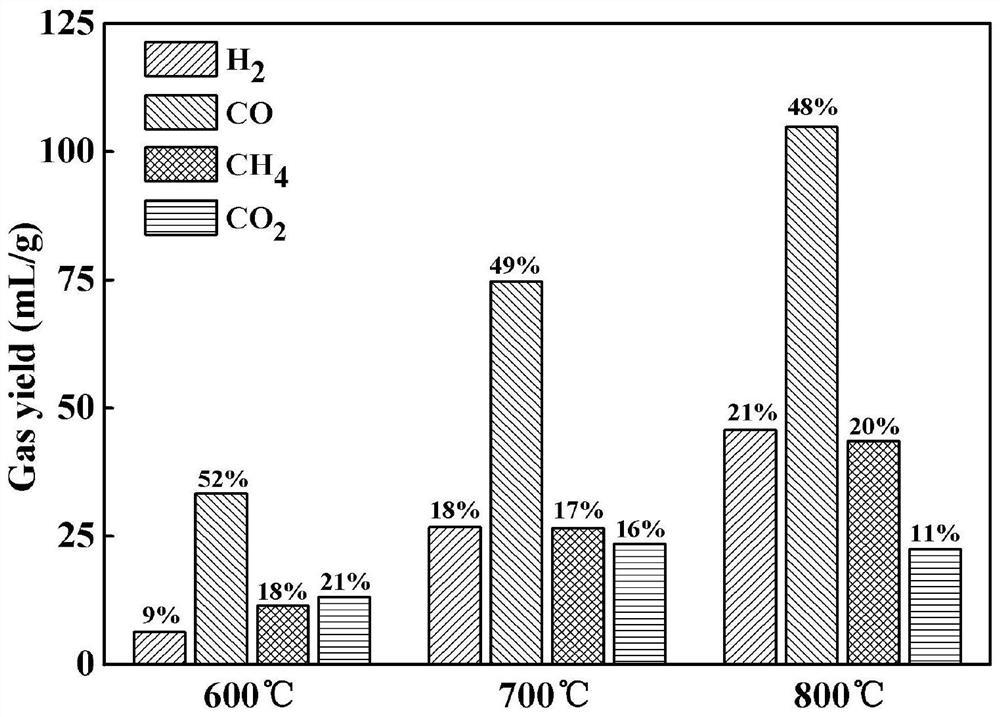

[0053] use as figure 1 The shown pyrolysis device reacts. In this example, under the condition of not adding dehydrated Fenton sludge, the influence of pyrolysis temperature on the pyrolysis gas output and gas components of soybean straw is explored. The operation process is as follows:

[0054] S1: Dry the soybean straw and crush it, pass through a 100-mesh sieve to make soybean straw powder, and take 2g of the soybean straw powder and place it in a porcelain boat;

[0055] S2: Adjust the porcelain boat to the inside of the upper end of the fixed bed reaction tube first, and compare figure 1 , the porcelain boat is located above the vertical tube furnace. Continuously feed Ar at a flow rate of 50mL / min into the fixed bed reaction tube, replace and exhaust the air in the fixed bed reaction tube, and heat up the fixed bed reaction tube through a vertical tube furnace;

[0056] S3: When the temperature of the fixed bed reaction tube rises to the pyrolysis temperature, the porc...

Embodiment 3

[0064] use as figure 1 The shown pyrolysis device reacts. In this example, under the condition of adding dehydrated Fenton sludge, the influence of pyrolysis temperature on the pyrolysis gas output and gas components of soybean straw is explored. The operation process is as follows:

[0065] S1: The dewatered Fenton sludge obtained in Example 1 was ground and passed through a 100-mesh sieve to make dewatered Fenton sludge powder. The soybean stalks are dried, pulverized, and passed through a 100-mesh sieve to prepare the soybean stalk powder.

[0066] S2: After uniformly mixing the dehydrated Fenton sludge powder obtained in step S1 with the soybean straw powder at a mass ratio of 1:5, a mixed powder is obtained. Take 2g of mixed powder and place it in a porcelain boat.

[0067] S2: Adjust the porcelain boat to the inside of the upper end of the fixed bed reaction tube first, and compare figure 1, the porcelain boat is located above the vertical tube furnace. Continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com