U-shaped fixed bed gasification-catalytic reaction device with tar degradation function

A technology of catalytic reaction and gasification reactor, which is applied in the direction of gasification catalyst, gasification process, petroleum industry, etc., can solve the problems of increased product gas purification cost, reduce the cost of post-purification treatment, prolong residence time, eliminate Effect of Particulate Matter and Tar Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

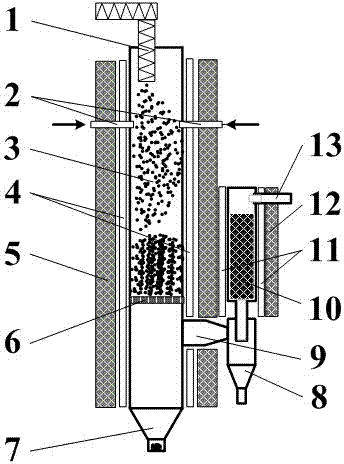

[0007] Such as figure 1 Shown, the U-shaped fixed-bed gasification-catalytic reaction device with tar degradation function of the present invention mainly comprises downdraft fixed-bed gasification reactor 3, updraft catalytic cracking reactor 10 and cyclone separator 8, and downdraft The suction-type fixed-bed gasification reactor 3 is in the shape of a cylinder, and the outer wall of the cylinder covers the first heating layer 4 and the first heat-insulation layer 5 successively from the wall to the outside. The feeding device 1 has a slagging outlet 7 at the bottom; the upper part has a gasification air distribution outlet 2 arranged tangentially to the wall, and the lower part has a tubular grate 6, which is arranged in parallel with a gap between each other. The gap is composed of steel pipes, a horizontal flue 9 is provided between the slagging outlet 7 and the tubular fire grate 6, and the updraft catalytic cracking reactor 10 is installed close to one side of the downd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com