Method of gasifying carbonaceous material and apparatus therefor

A carbon monoxide and organic material technology, applied in the details of gasification device, mechanical details of gasification device, gasification process, etc., can solve the problems of low gasification efficiency and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

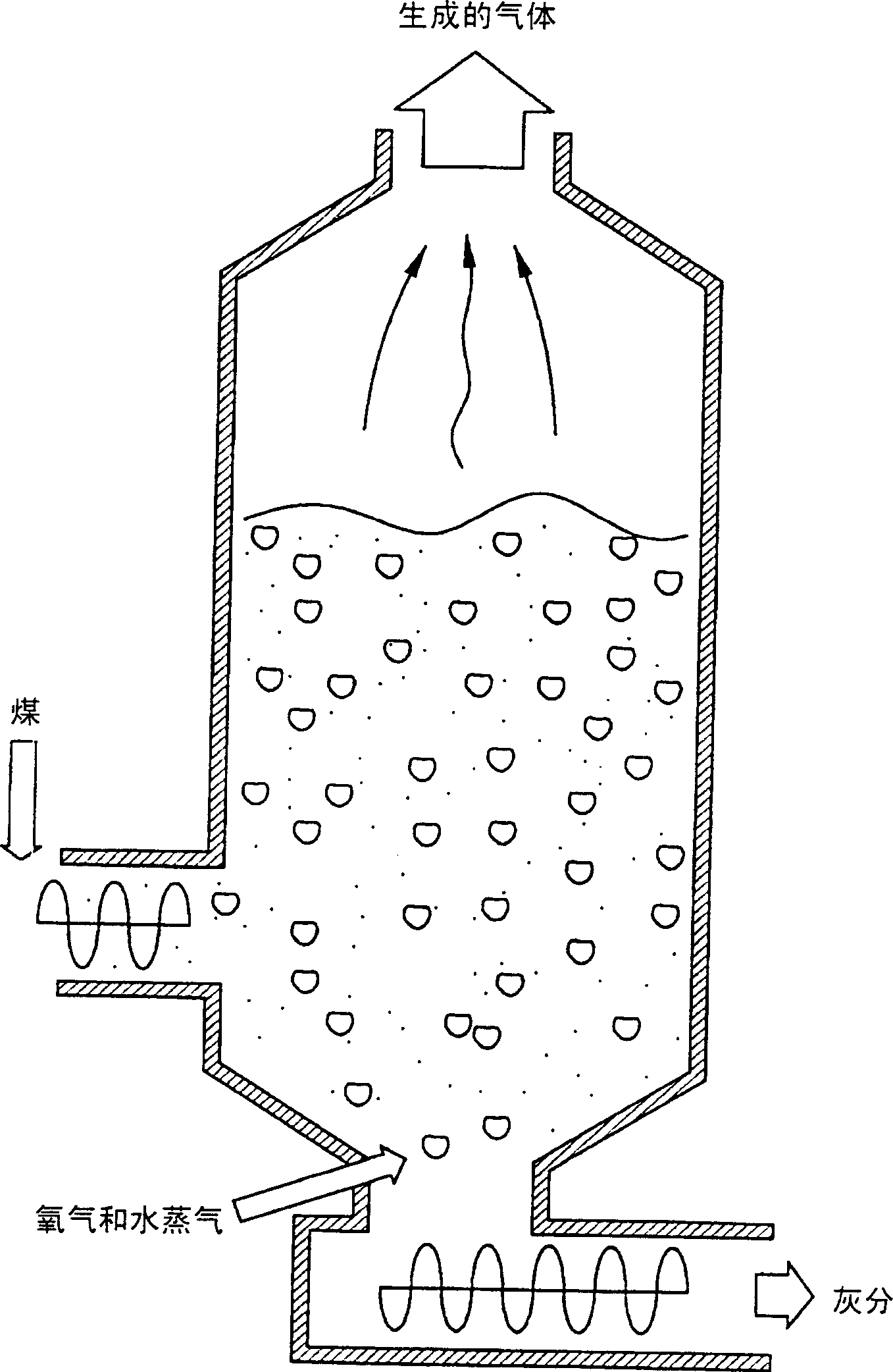

[0115] waste oil at a rate of 10 kg / h in figure 2gasification in the gasification reactor shown in . The diameter of the reactor was 250 mm and the total length was 2000 mm, including the upper and lower end sections. At the lower end of the reactor, gas supply nozzles and oxygen supply nozzles respectively connected to the generated gas recirculation pipe and the oxygen supplier are installed on the wall along the tangential direction. At the lowermost end of the reactor, a burner for preheating the reactor to about 600° C. in the early stage of the reaction was installed. After preheating the reactor to 600° C., the burner was removed to equip an ash trap for trapping the ash remaining after the gasification reaction. In addition, an observation port for observing the state of the reaction carried out in the reactor and equipment for determining the temperature and pressure in the reactor were installed in the flange plate on the wall of the reactor.

[0116] At the gasif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com