Internal combustion type biomass gasifier

A technology of gasification furnace and biomass, which is applied in the direction of gasification process, gasification catalyst, and the manufacture of combustible gas, etc., which can solve the problem of large-scale promotion and use of down-suction gasification furnaces, large damage to gasification equipment, and unfavorable gas quality. Gas volume and other issues, to achieve the effect of improving utilization rate and gas quality, quick and convenient removal, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

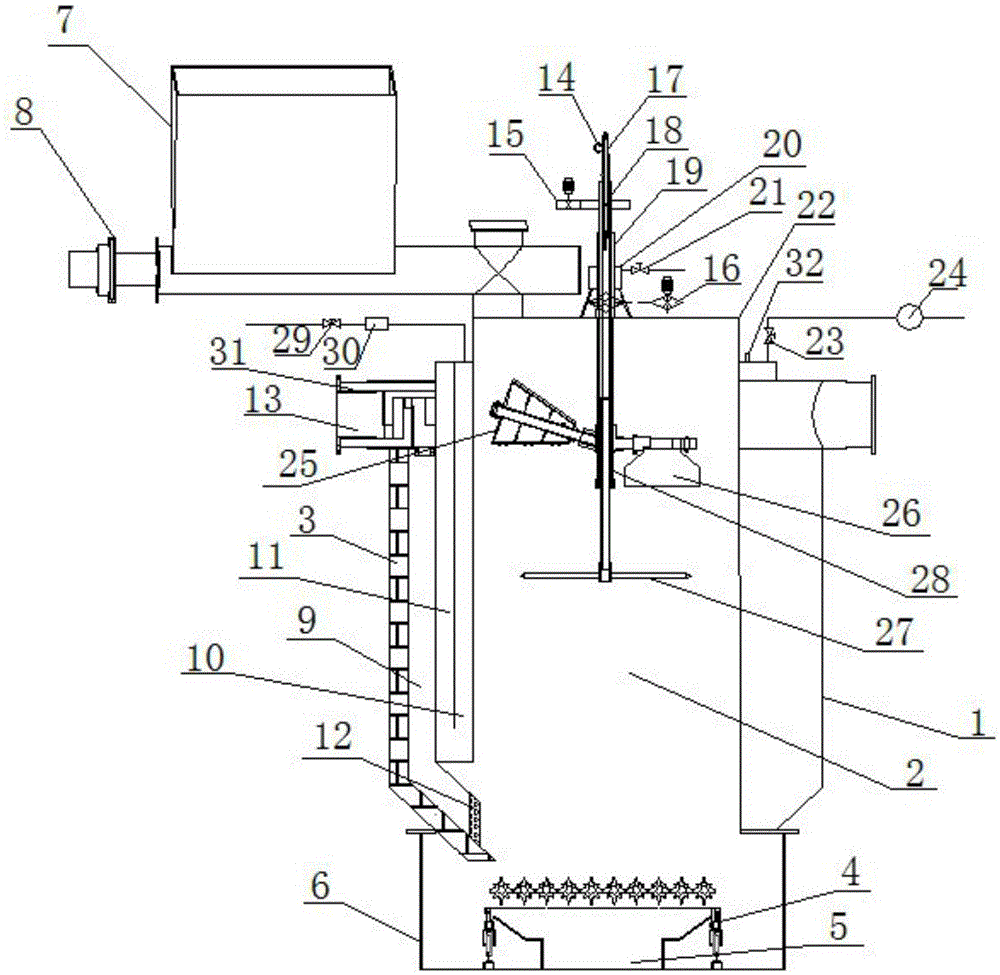

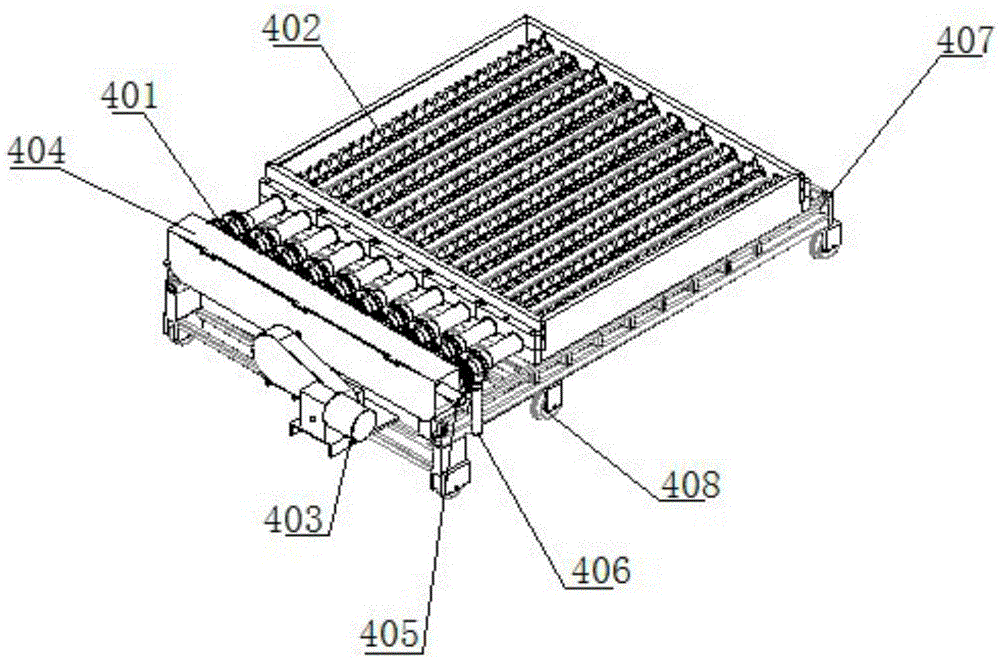

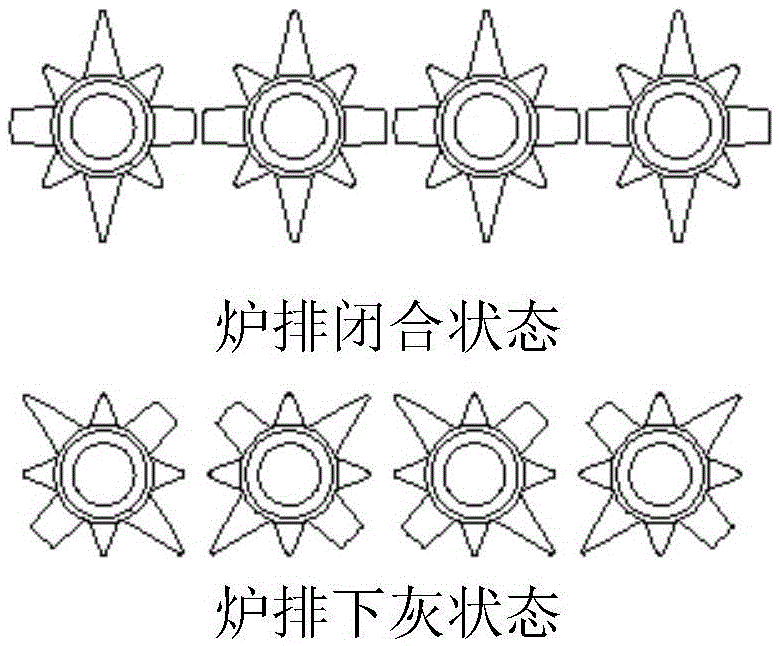

[0018] like figure 1 As shown, an internal combustion biomass gasification furnace includes a furnace body 1 and a furnace 2, a supporting base 6 is provided at the lower part of the furnace body, and an ash dropping device 4, an ash discharging device 5, and an ash dropping device 4 are arranged in the base 6 Installed on the ash-discharging device 5, the two cooperate. A sealing cover 22 is arranged on the upper part of the furnace body 1, and the sealing cover 22 is connected with the screw feeding device 8, and the material enters the screw feeding device 8 through the hopper 7. In the middle of the upper part of the sealing cover 1, there is a stirring joint 27 driven by the perforation lifting device 14 through gear transmission and driven by the lifting thread suspension shaft 17. The stirring joint 27 is placed in the furnace 2, and the stirring joint 27 can move up and down. Lifting thread suspension shaft 17 part is built in broken perforated rotating hollow shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com