Device and method for reforming biomass tar to produce syngas

A biomass and synthesis gas technology, applied in the manufacture of combustible gas, gasification process, petroleum industry, etc., can solve the problems of tar conversion and resource utilization, and achieve the effects of improving stability, reducing consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

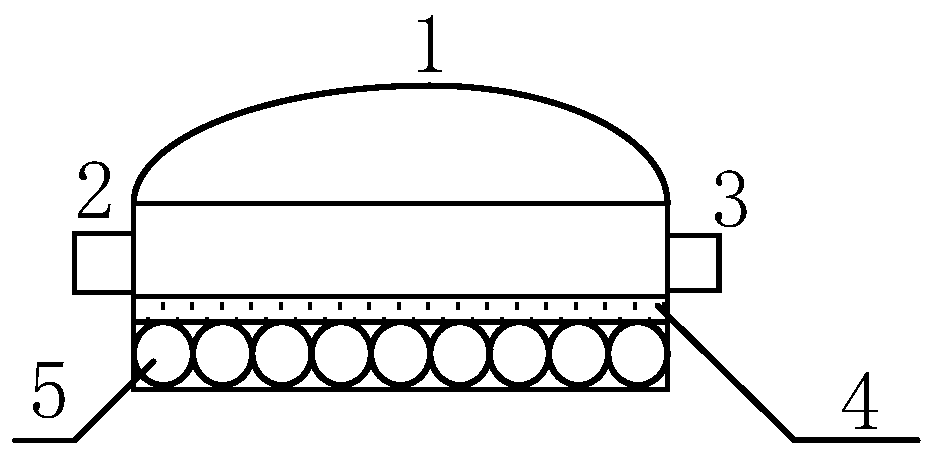

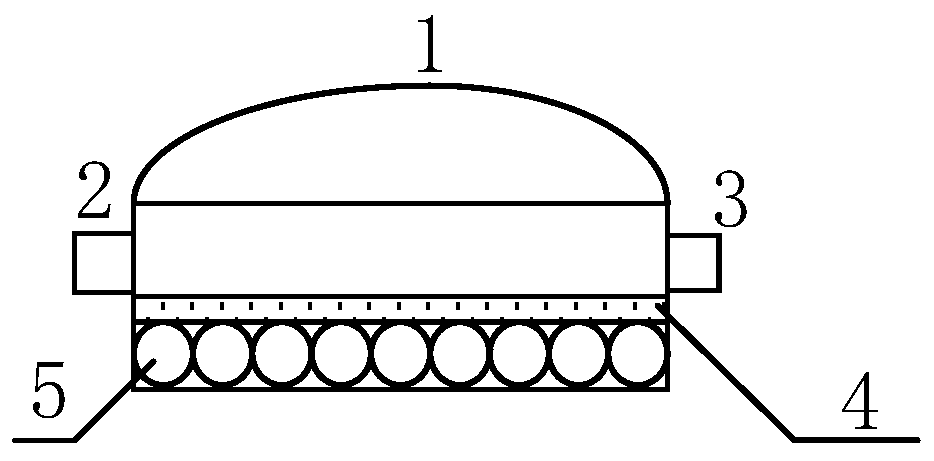

[0023] A device for producing synthesis gas from biomass tar reforming of the present invention comprises: a solar transmission window, a material inlet, a material outlet, a catalyst loading plate, and a heating pipe; the solar transmission window is arranged on the upper part of the device and is an arch shaped structure; a catalyst loading plate is provided below the solar transmission window, and the material inlet and material outlet are respectively located at the two ends between the solar transmission window and the catalyst loading plate, and the surface of the catalyst loading plate is filled with catalyst particles. A heating tube is arranged on the lower surface of the catalyst loading plate; a heating medium passes through the heating tube. The solar energy transmission window material is high borosilicate glass, and the solar energy transmission rate is greater than 92%; the catalyst loading plate is a trough structure, and the catalyst is made of one or more meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com