Methods and systems for supplying hydrogen to a hydrocatalytic reaction

A technology for hydrogenation catalysis and catalyst, which is applied in chemical instruments and methods, gasification catalysts, and catalytic treatment of combustible gases, etc., and can solve problems such as problems, complex engineering challenges, and high cost system downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

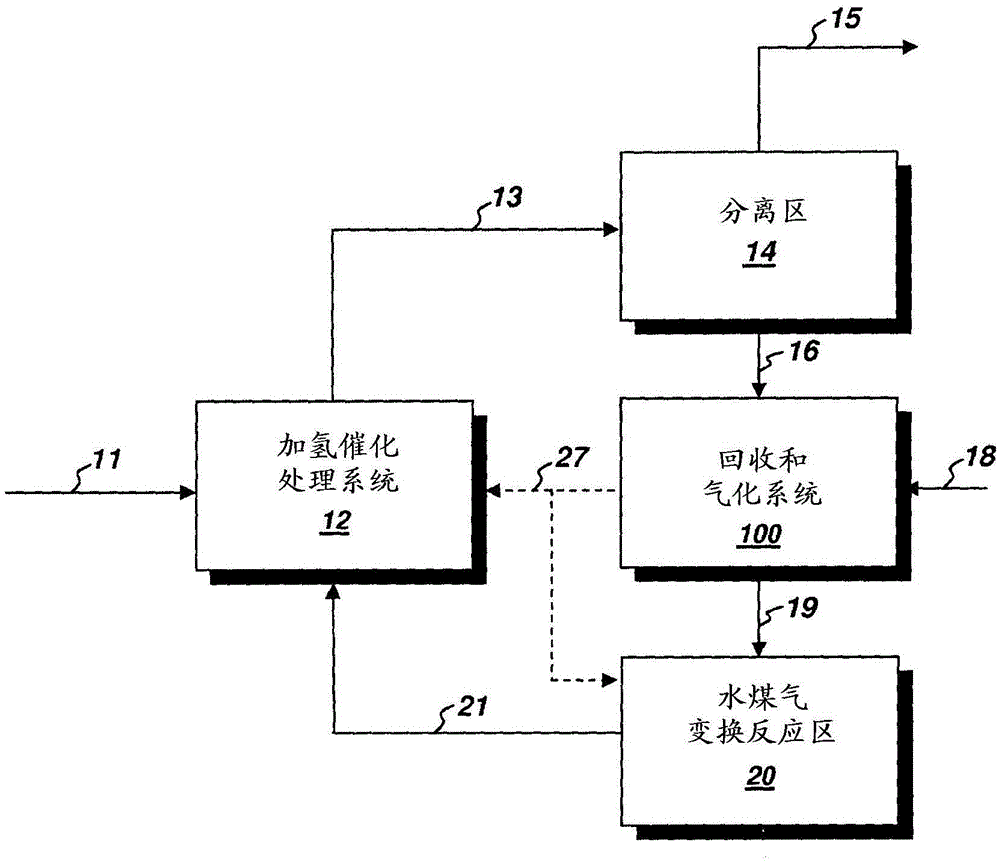

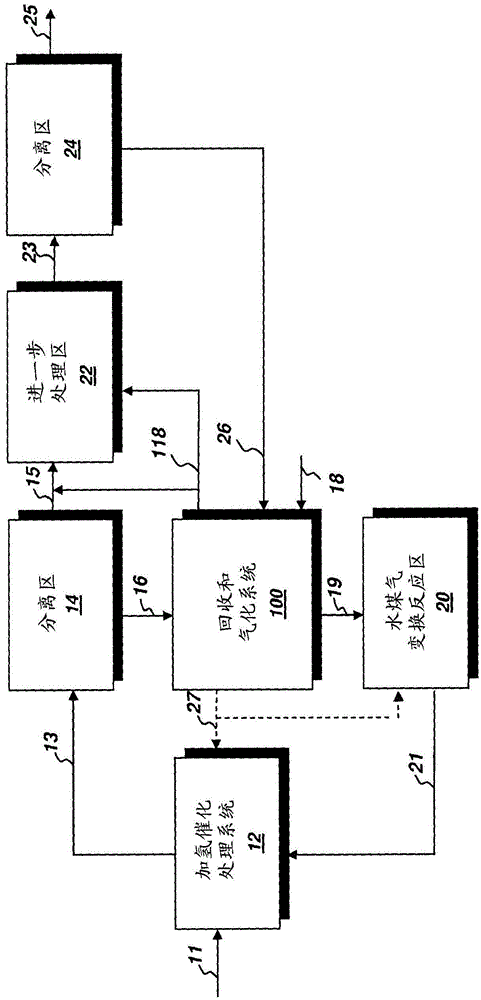

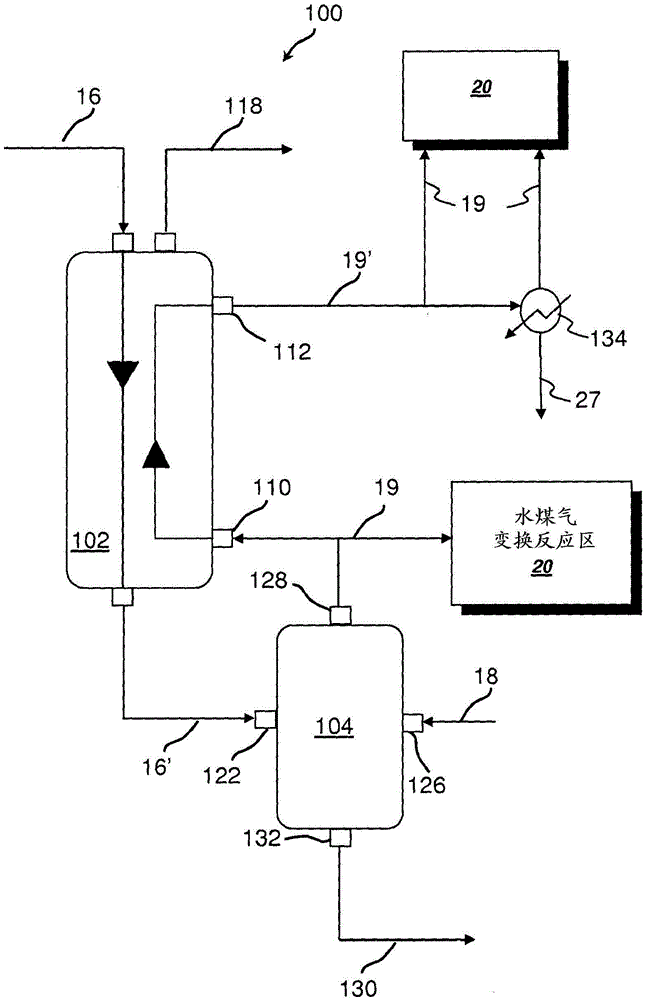

Method used

Image

Examples

Embodiment 1

[0142] Example 1: A 100-ml Parr reactor was charged with 60.18 grams of deionized water solvent and 0.754 grams of a nickel oxide-promoted cobalt molybdate catalyst (DC-2534, 1–10% on alumina obtained from Criterion Catalyst & Technologies L.P. cobalt oxide and molybdenum trioxide (up to 30 wt%) and less than 2% nickel). The catalyst was sulfided using the method described in Example 5 of US Patent Application Publication No. 2010 / 0236988. About 5.05 grams of southern pine wood chips (39% moisture, nominal dimensions about 3mmx5mmx5mm) and about 0.195 grams of potassium carbonate buffer were added to the reactor, which was then pressurized with 54 bar of hydrogen under magnetic stirring. The stirred reactor was heated to 190°C for 1 hour. Subsequently, the reactor was heated to 250° C. for 5 hours, which was the end point of the cycle. A sample of approximately 1-2 grams of the mixed product was withdrawn at the end of the cycle through a 0.5 micron sintered metal dip tube w...

Embodiment 2

[0145] Embodiment 2: Repeat embodiment 1 with 60.06 grams of 25% ethanol in water as solvent and 0.749 grams of cobalt molybdate sulfide catalyst. The reactor was pressurized to 52 bar with hydrogen and heated to 190°C for 1 hour, then to 250°C for 3 hours, and then to 270°C for 2 hours. After 8 cycles with each addition of 6 grams of wood as described in Example 1 above, a viscous phase was observed to form inside the reactor. The viscous phase exhibits a viscosity greater than 1000 cP at room temperature. This phase was separated using liquid-liquid separation to yield a bottoms fraction. Analysis of the heavy bottoms fraction again indicated the presence of compounds boiling above the boiling point of n-butanol, including tetrahydrofurfuryl alcohol, methoxypropylphenol, and propylphenol. The total weight percent of species detected in the bottoms fraction was less than 100%, indicating the presence of higher molecular weight oligomers that could not elute from the heated ...

Embodiment 3

[0146] Example 3: Example 1 was repeated with 50% ethanol in water as solvent. After 10 cycles of chip addition as described in Example 1 above, a heavy viscous phase was observed coating the interior and bottom of the reactor with a viscosity greater than 10,000 cP. The wood additions included 6.05, 6.06, 6.06, 6.06, 6.01, 6.00, 6.01, 6.02, 6.06 and 6.06 grams to complete 10 cycles. After 10 cycles, at 52bar H 2 and 290°C for 5 hours, after which the viscosity of the lower layer was reduced to less than about 500 cP. High temperature hydrogen treatment resulted in increased formation of methoxyl and alkylphenols such that the weight percent of compounds observed in GC was more than 3 times that of similar phases formed in Example 2. The treated phase can be subjected to rectification to remove low volatility components elutable by the GC injector. The remaining bottoms fraction containing heavy components (which includes weight percents not seen in GC analysis) can be gasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com