System for transforming waste combustible material recovered from building rubbish into clean gas

A construction waste and clean technology is applied in the system field of converting into clean gas, which can solve the problems of high catalytic reaction temperature, poor catalytic effect, and high content of harmful substances in the exhaust gas, and achieve the effects of low cost and large output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

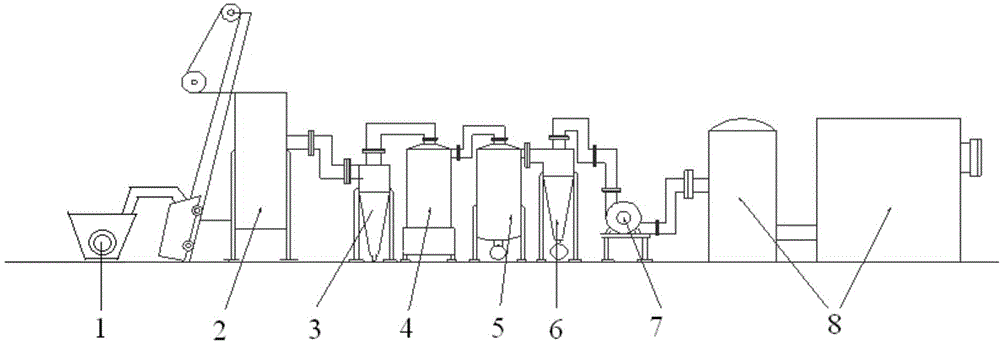

[0044]The present invention is a clean gas conversion system for waste combustibles recovered from construction waste. The system includes a comprehensive raw material processing unit 1, a temperature-controlled cracking furnace 2, a primary purifier 3, a secondary purifier 4, a primary separator 5, and a secondary purifier. Stage separator 6, Roots air blower 7, three-stage purifier and the connecting pipeline 8 therein, the outer wall of the described temperature-controlled cracking furnace is provided with a spiral flue, and the described flue is arranged on the temperature-controlled cracking furnace 2 The input end of the thermostat is connected, the output end of the thermostat is connected to the primary purifier 3, the front end of the secondary purifier 4 is connected to the primary purifier 3, the rear end is connected to the primary separator 3, and the secon...

Embodiment 2

[0047] Use the system of Example 1 to perform clean gas conversion of combustibles recovered from construction waste, wherein the waste combustibles recovered from construction waste are cracked and gasified in a temperature-controlled cracking furnace, followed by primary purification and secondary purification , and then perform primary separation and secondary separation. After the secondary separation, the tail gas is drawn out by a fan for tertiary purification. The construction waste is waste from building demolition, and its combustibles include wood products, plastics, textiles and the like. The catalyst used in the cracking process includes a carrier and active components loaded on the carrier, wherein the carrier is fly ash, and the catalytically active components are NiO, CuO, Fe 2 o 3 A composite oxide of three oxides, the catalyst is expressed as NiO-CuO-Fe 2 o 3 / fly ash, wherein the molar ratio of Ni, Cu, Fe is 5:1:15, based on the total weight of the cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com