Novel brown coal gasification process

A coal gasification and process technology, applied in the field of coal gasification, can solve the problems of insufficient utilization of oxidants, incomplete combustion and conversion of coal and other fuels, etc., and achieve the effects of no pollutant emissions, reduced raw material costs, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

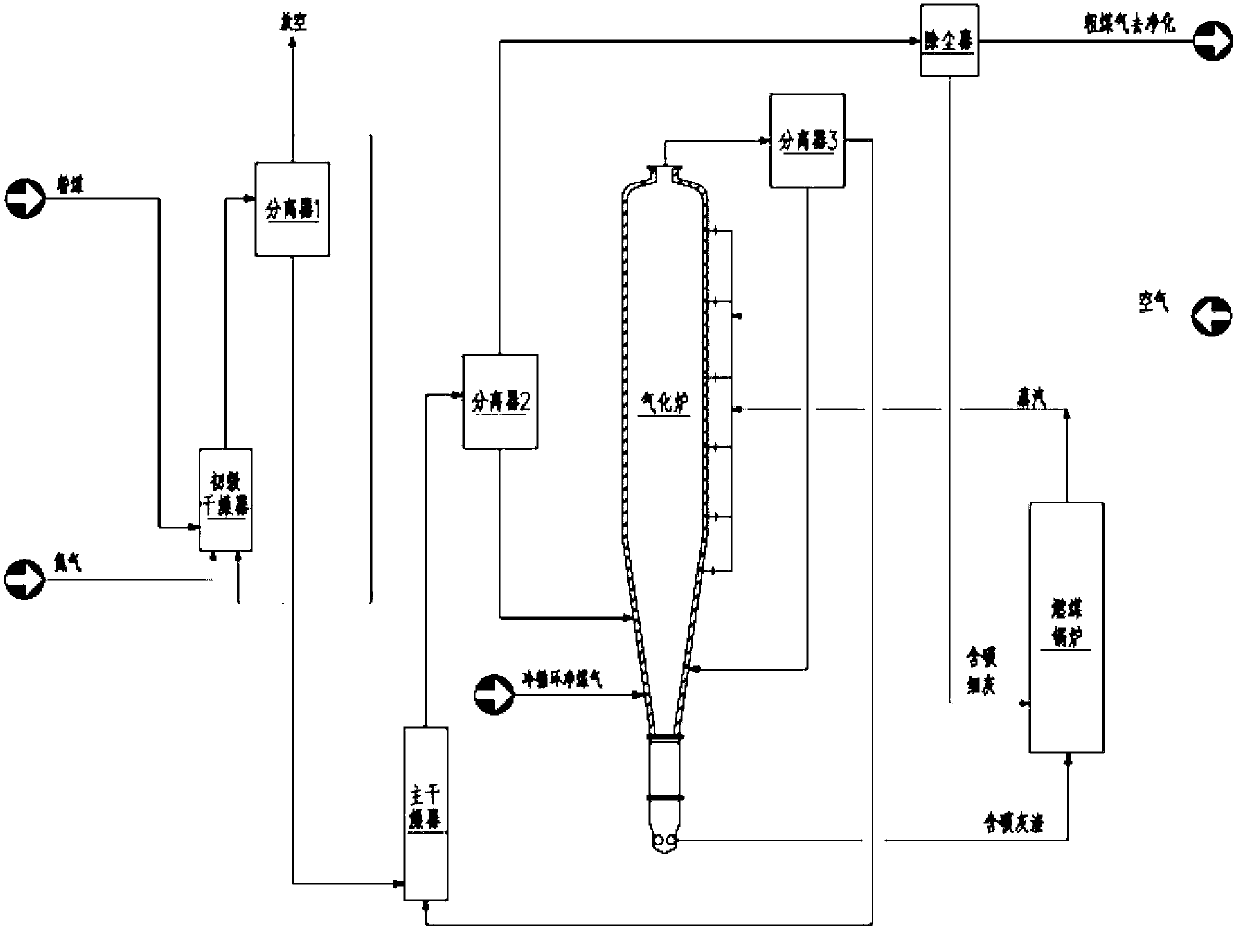

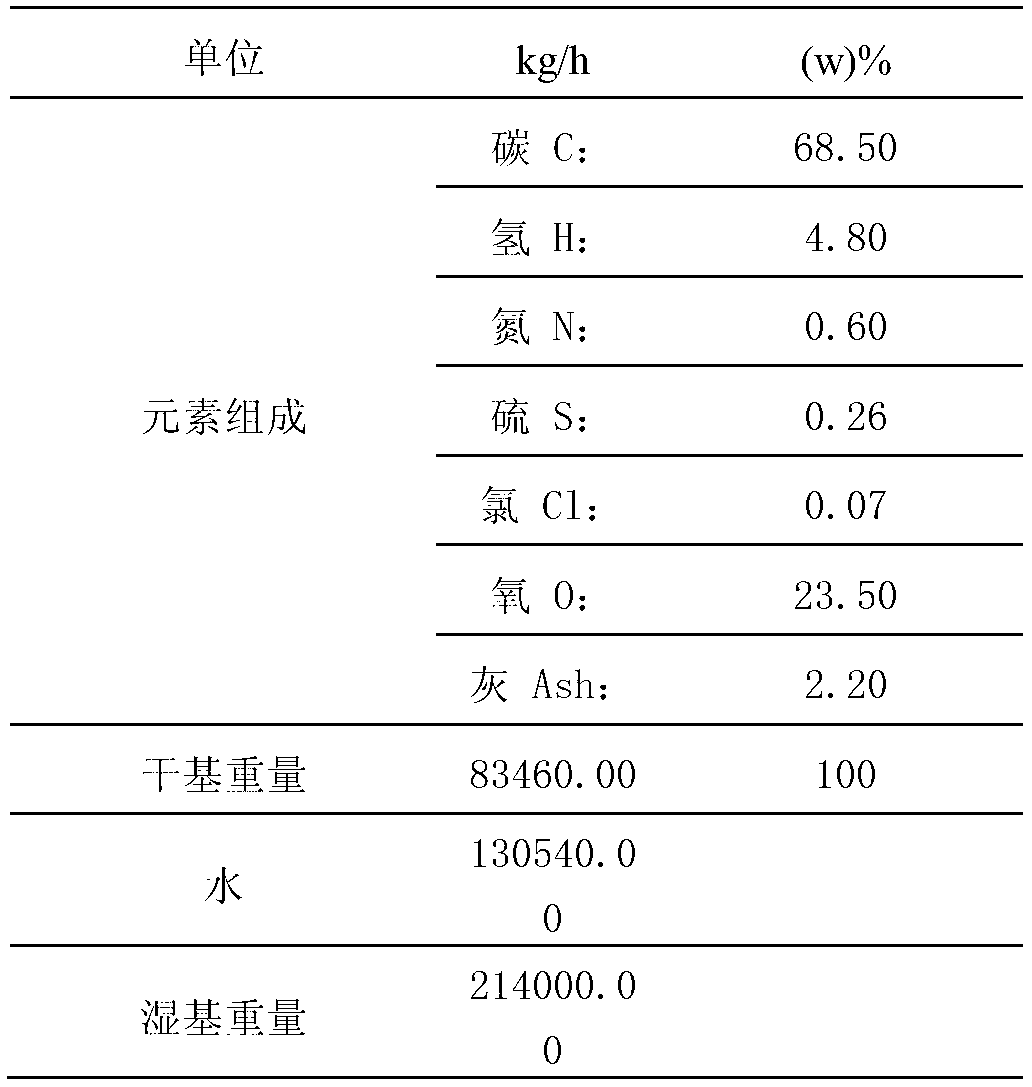

[0023] Example 1: A lignite gasification process with daily lignite processing capacity of 53126t. The lignite coal quality composition is shown in Table 1. The lignite pulverized coal is sent to the primary dryer through the coal storage and transportation system for primary drying (at a temperature of 150°C). It is sent to the main dryer for further drying, part of the circulating gas exiting the separator 1 is emptied, and the rest is returned to the primary dryer for circulation, and a certain amount of nitrogen is added to the primary dryer to maintain the balance of the circulating gas. In the main dryer, high-temperature coal gas (650°C) directly dries and heats the pulverized coal to further reduce the moisture content of the pulverized coal to meet the reaction requirements of the gasifier. At the same time, part of the volatile matter in the coal powder is also separated. The pulverized coal, volatile matter and crude gas coming out of the main dryer enter the separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com