Minimal sour gas emission for an integrated gasification combined cycle complex

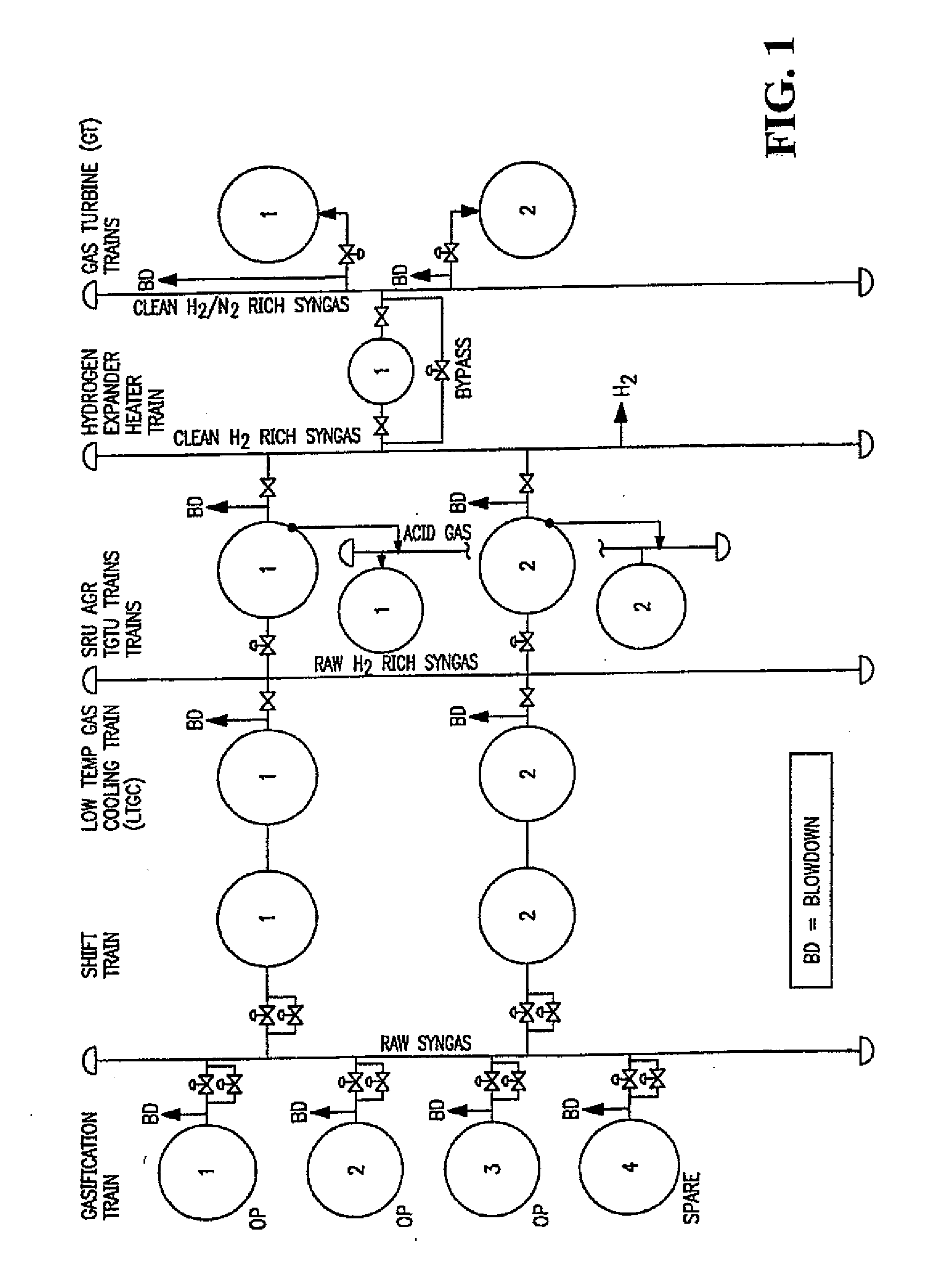

a gasification combined cycle and gas emission technology, applied in the direction of gasification process details, gas contaminants removal, inorganic chemistry, etc., can solve the problems of high sulfur emission, less nitrogen in the product, and less than normal nitrogen emission of contaminants such as sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

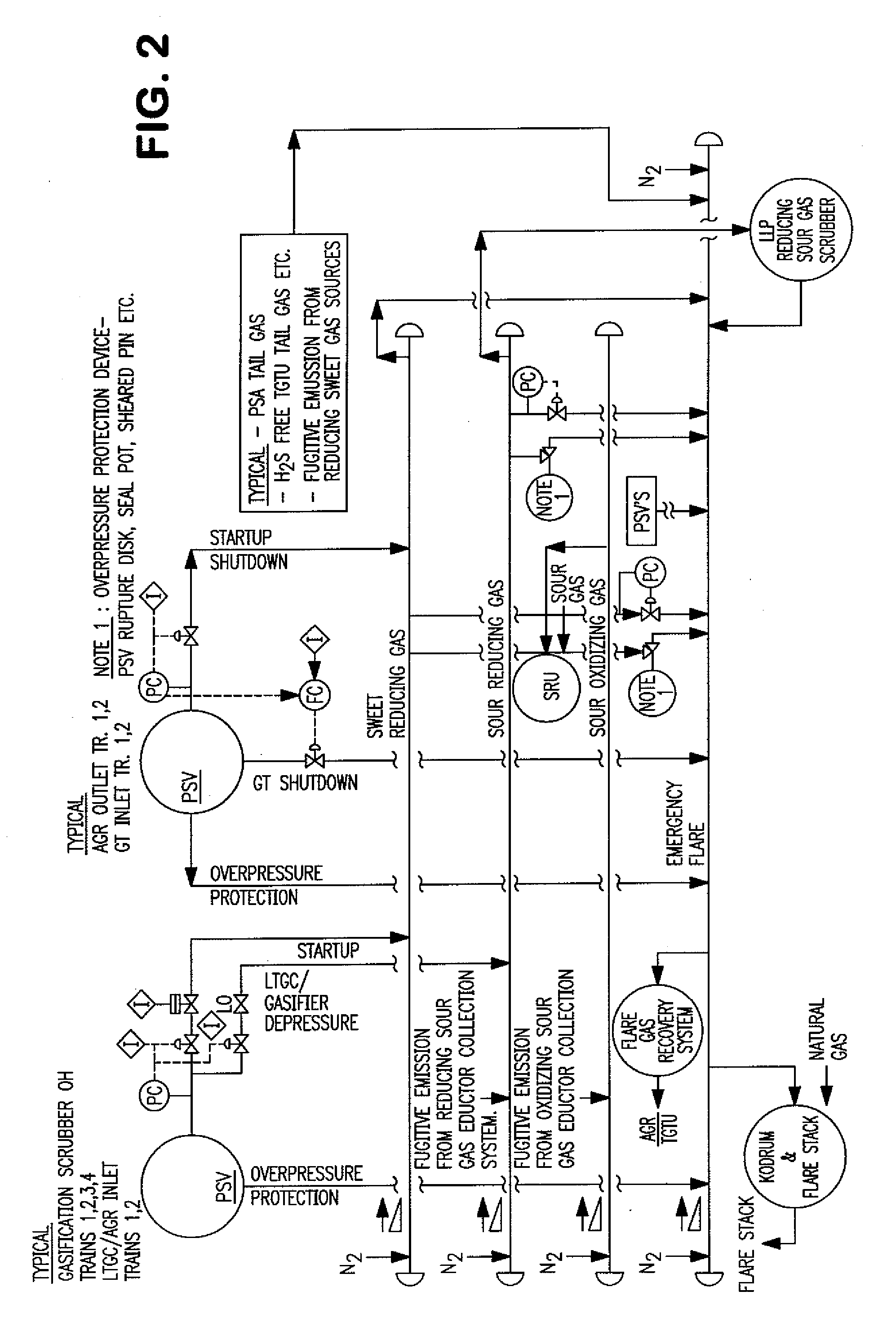

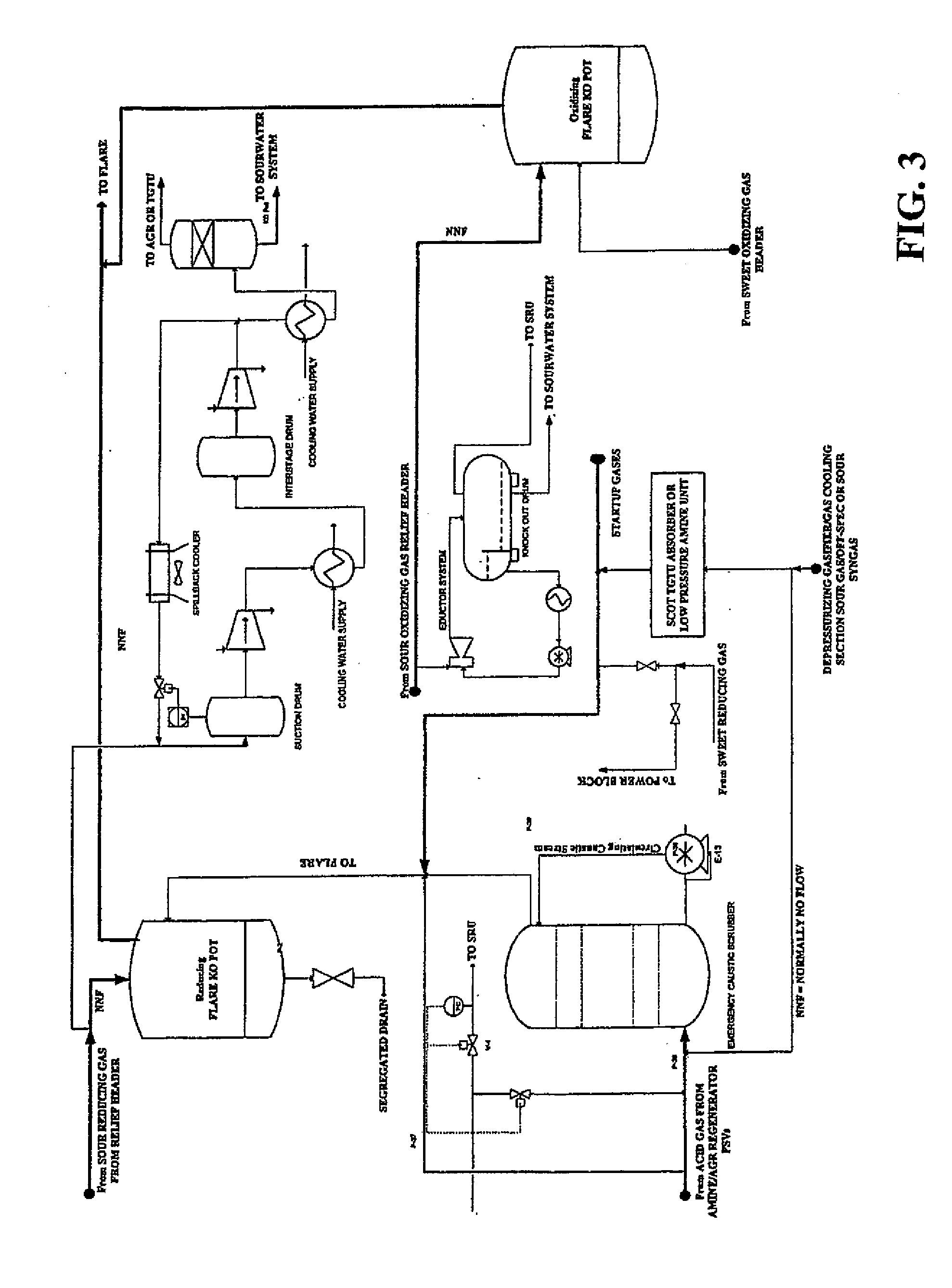

[0036]Broadly, in accordance with the present invention the syngas production zone or gasifier in an IGCC complex is started up with a clean, sulfur-free, containing less than about 10 ppmv sulfur hydrocarbon-containing feedstock such as natural gas or a light hydrocarbon liquid such as methanol. The sulfur-free syngas produced in the gasifier, a sweet reducing gas, is then sent to a flare. When the downstream acid gas removal unit and the sulfur recovery unit and the tail gas treatment unit are commissioned, the clean fuel is switched to a high sulfur solid fuel. After the AGR is fully commissioned, the acid gas (H2S and other contaminants) are concentrated and sent to a sulfur recovery unit e.g. Claus unit to make elemental sulfur. If the acid gas concentration is less than 25% vol H2S in the acid gas during the start-up, such acid gas is routed to a sour gas scrubber such as an emergency caustic scrubber. Once the SRU is operational, the small amount of unconverted H2S in the eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com