Energy-balance-based coordination control method of integrated gasification combined cycle power station

An integrated coal gasification and combined cycle technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the unrealized decoupling control of power island and gasification island, poor coordination of time constant difference, poor control effect, etc. problems, to achieve the effect of improving the automatic input rate and control quality, reducing labor intensity, and being easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the implementation method and advantages of the technical solution of the present invention more clear, the specific implementation method will be described in detail below in conjunction with the implementation manner and the accompanying drawings. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

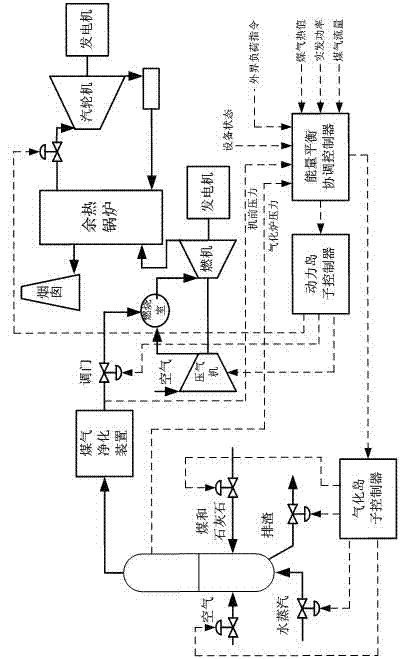

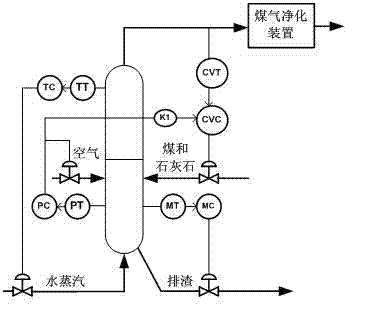

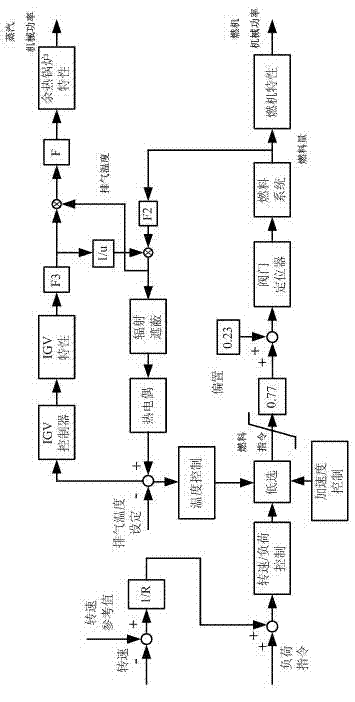

[0020] The control method proposed by the present invention is mainly divided into two aspects: one is the structural design of the coordinated control system based on the principle of energy balance to ensure the rationality and effectiveness of the control method; the other is the adjustment of the controller parameters according to the actual operating characteristics of the equipment to Ensure the smooth operation of each equipment and the rapid response to load. The technical solutions of the present invention will be further described below in conjunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com