Sodium-ion battery and preparation method thereof

A sodium ion battery and sodium ion technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problem that sodium ion batteries are difficult to simultaneously take into account high sodium intercalation capacity and good dynamic characteristics, and achieve rich raw materials , low cost, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In the second aspect, an embodiment of the present invention provides a method for preparing a sodium ion battery, including the following steps:

[0051] Take the positive electrode active material, the conductive agent, the binder and the organic solvent, mix and stir to prepare the positive electrode slurry, coat the positive electrode slurry on the current collector, dry and roll to prepare the positive electrode sheet. The cathode active material is Na X CoO 2 , Na X MnO 2 , Na X TiS 2 , Na X NbS 2 Cl 2 , Na X WO 3-X , Na X V 0.5 Cr 0.5 S, amorphous Na X MoS 3 Or Na X TaS 2 , In each formula, 0X Ni 0.5 Mn 0.5 O 2 , NaVPO 4 F or Na 2 FePO 4 F;

[0052] Take the negative electrode active material, the conductive agent, the binder and the organic solvent, mix and stir to prepare the negative electrode slurry, coat the negative electrode slurry on the current collector, dry and roll to prepare the negative electrode sheet. The anode active material is MoS 2 ;

[0053] The po...

Embodiment 1

[0063] A preparation method of sodium ion battery includes the following steps:

[0064] MoS 2 Synthesis:

[0065] Add 2mmol of Na 2 MoO 4 And 6mmol of CH 3 CSNH 2 Add to 30mL of distilled water to form a mixed solution. Then, under stirring, 10mol / L HCl was added dropwise to the mixed solution to adjust the pH value of the mixed solution to less than 1. The mixed solution was transferred to a stainless steel hydrothermal kettle with a polytetrafluoroethylene liner and heated at 240°C for 36 hours. After the reaction kettle is cooled to room temperature, the precipitate obtained is filtered, washed repeatedly with distilled water, and then the precipitate is heated at 400°C for 2 hours under the protection of argon to prepare MoS 2 . Before treatment, the tube furnace is pre-evacuated and filled with pure argon at normal pressure.

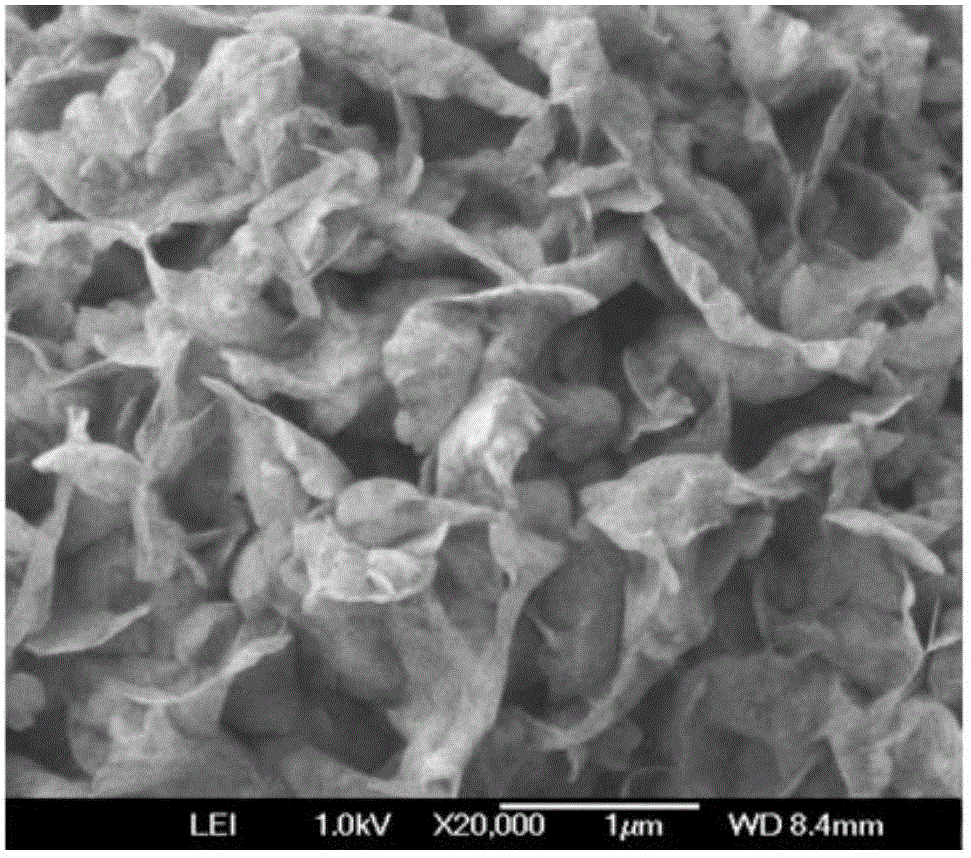

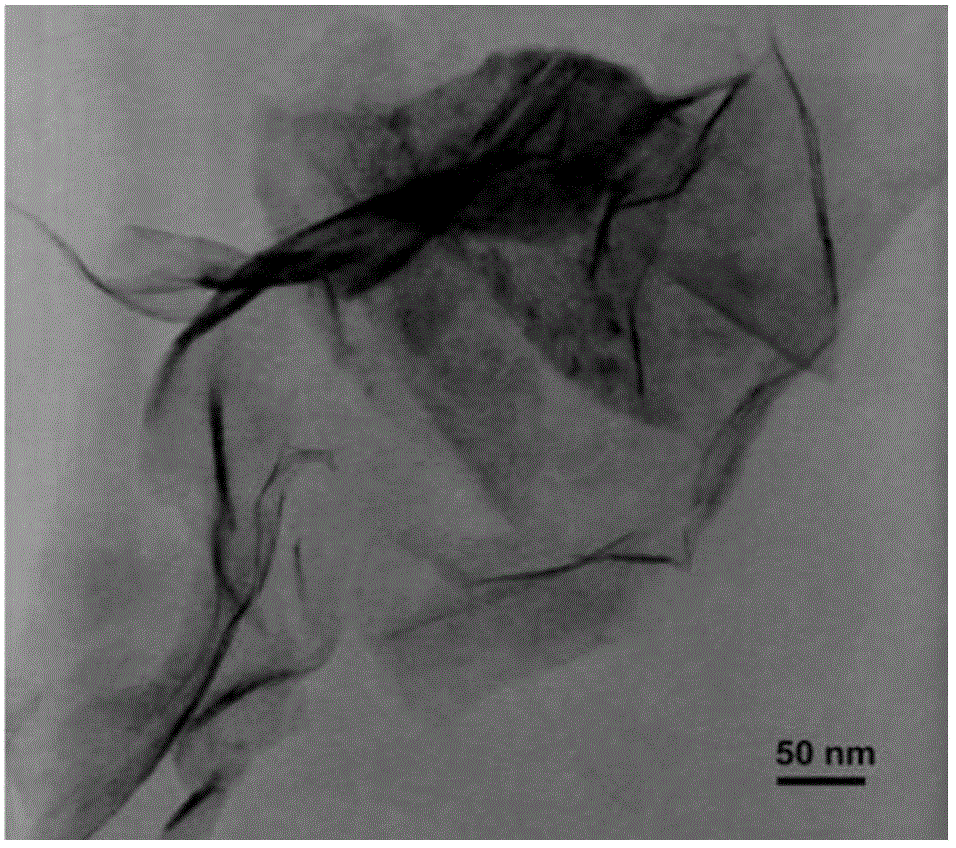

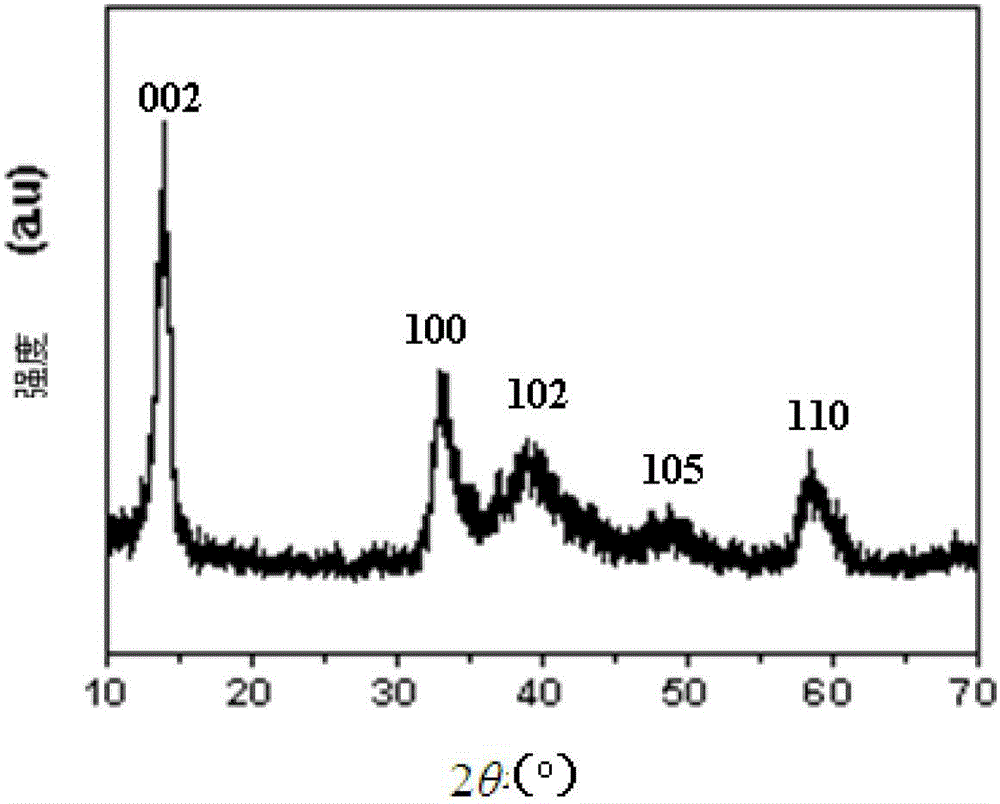

[0066] MoS was performed on JSM-7401F field emission scanning electron microscope (FESEM) and JEM-2010F transmission electron microscope (TEM) 2 Chara...

Embodiment 2

[0079] A sodium ion battery including:

[0080] Positive pole piece, including positive active material Na 0.5 CoO 2 And aluminum current collector,

[0081] Negative pole piece, including negative active material MoS 2 And copper current collector,

[0082] Non-aqueous organic electrolyte, including sodium salt NaClO 4 And organic solvents (500 g EC, 500 g DMC and 500 g DEC), and

[0083] Composite diaphragm composed of polypropylene and polyethylene.

[0084] The preparation method is the same as the preparation method of the sodium ion secondary battery in Example 1, except that the positive electrode active material is different from the sodium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com