Acid and alkali resource recovery process technology from sodium saponification waste water

A treatment process, sodium saponification technology, applied in the field of realizing zero discharge of rare earth separation industrial sodium saponification wastewater and acid-base resource treatment process, can solve the problems of waste of energy, complex components, high operating costs, etc., to reduce energy consumption and desalination High rate, guaranteed removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

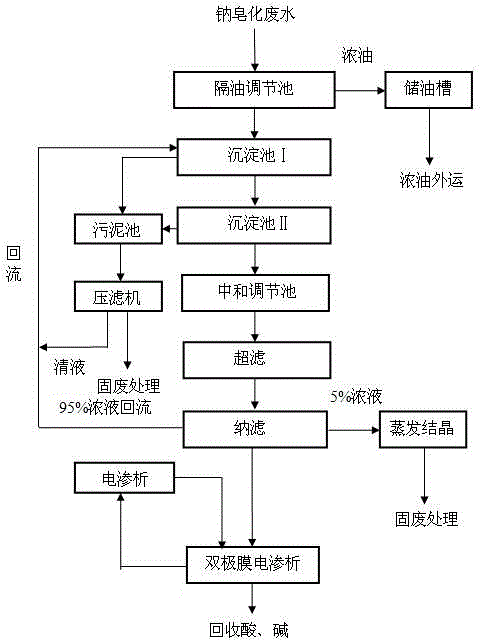

Method used

Image

Examples

Embodiment 1

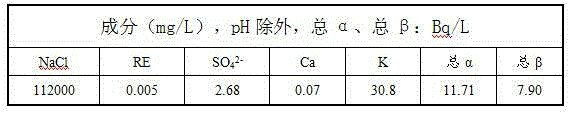

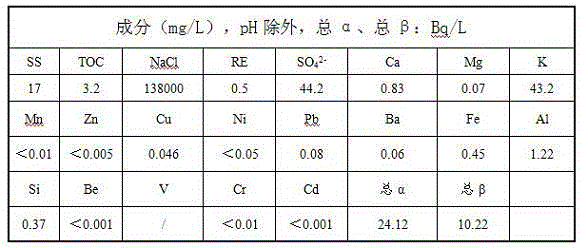

[0036] 1. The sodium saponification wastewater discharged from the production process of a company’s rare earth separation project is used as the raw water of this example. The specific water quality data are shown in Table 1.

[0037] Table 1 Influent Water Quality

[0038]

[0039] 2. Discharge the sodium saponification wastewater into the oil separation adjustment tank for more than 4 hours, and discharge the slick oil from the oil collection pipe to the oil storage tank.

[0040] 3. The effluent from the oil separation adjustment tank enters the sedimentation tank Ⅰ, and calcium hydroxide is added to adjust the pH value, and the sludge is discharged into the sludge tank through the sludge discharge pipe.

[0041] 4. The effluent from sedimentation tank I enters sedimentation tank II, and calcium hydroxide is added to adjust the pH value, and then sodium carbonate solution is added, and the sludge is deposited into the sludge tank, and the sludge in the sludge tank is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com