Method and system for preventing boiler heating surface from being contaminated through circulation of wearable materials

A material circulation and heating surface technology, applied in the field of boilers, can solve problems such as difficulties, decrease in the heat transfer effect of the flow heating surface, affecting the long-term safe and stable operation of the boiler, achieve low initial investment and operating costs, and avoid serious contamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following non-limiting examples illustrate the invention.

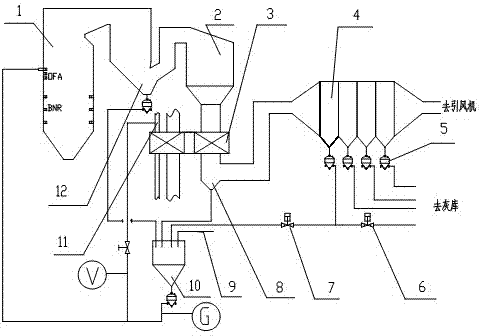

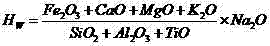

[0039] According to the tendency of coal ash to stain and the content of the ash The content has the characteristics of negative correlation characteristics, and the high The wear-resistant material with high content - the mixture of quartz sand (or pure river sand) and large particle fly ash is sent to the boiler 1 combustion air area for combustion, and is fully mixed with the boiler flue gas before entering convection heating. On the one hand, due to As the concentration of fly ash increases, the Na captured by fly ash + The increase can greatly reduce the proportion deposited on the tube wall of the convective heating surface; on the other hand, the use of wear-resistant materials and large particles of fly ash to continuously remove the contaminated layer on the tube wall of the convective heating surface can realize the Self-cleaning of walls. Most of the quartz sand and large particle fly ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com