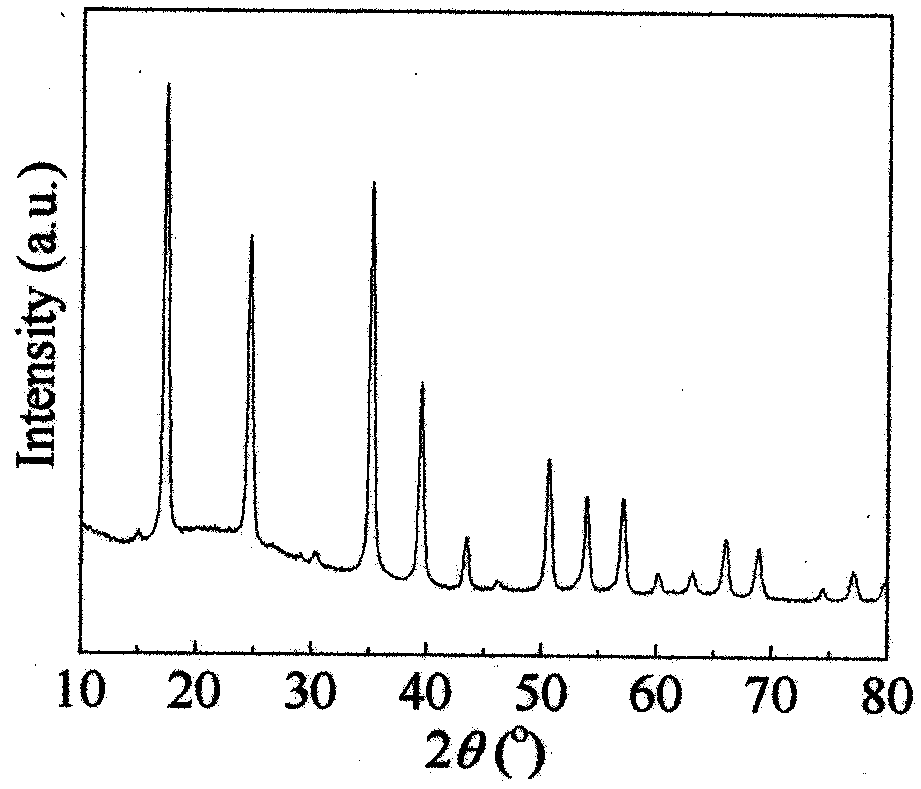

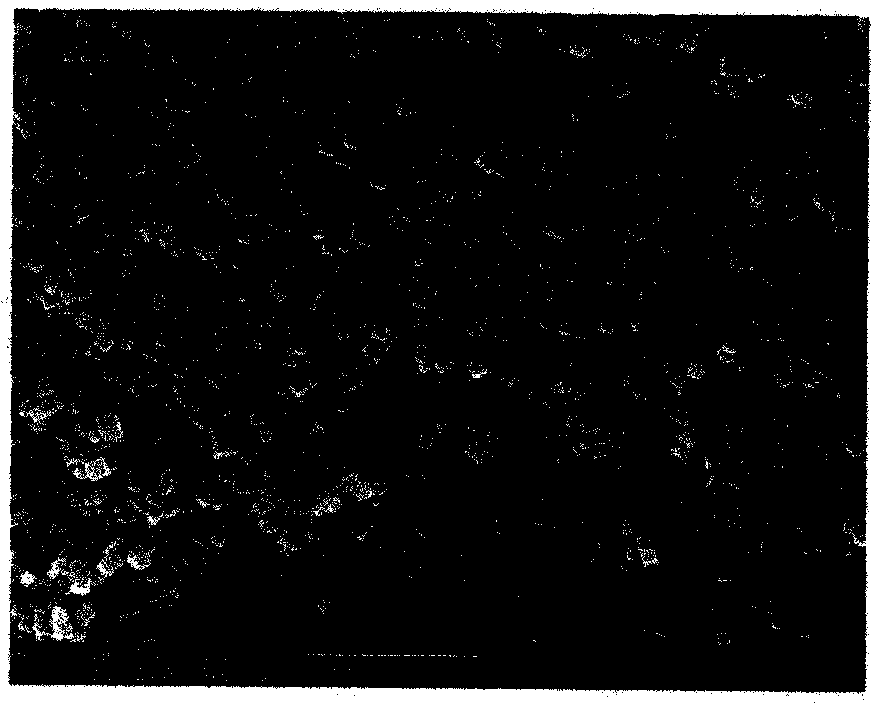

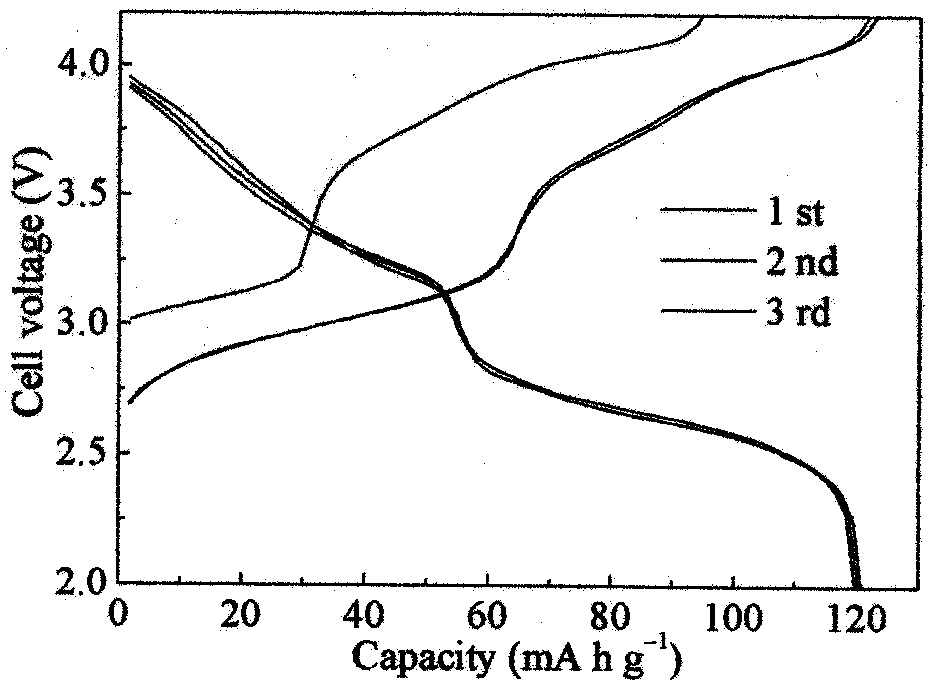

Method for synthesizing high-sodium iron-based Prussian blue electrode material

A synthesis method and electrode material technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as large-scale energy storage, high cost of lithium-ion batteries, and limited reserves of lithium raw materials, and achieve a simple and reasonable synthesis method. Ease of industrial production and regular appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Taking 100g of the finished product of the electrode material as the meter, the molar percentages of the required raw materials are as follows: 60g of ferrous chloride is selected as the metal salt containing iron ions, and the molar percentage is 26%, and the metal salt containing ferricyanide ions is sodium ferrocyanide 145g, the molar percentage is 26%, the complexing agent selects sodium citrate 160g, and the molar percentage is 48%.

[0029] The synthesis method is as follows:

[0030] Step 1. According to the ratio of raw materials, take iron ion-containing metal salt and complexing agent into a container, add 10L solvent and mix evenly to become solution A for use;

[0031] Step 2, according to the ratio of raw materials, take metal salt containing ferricyanide ion and put it into a container, add 10L solvent and mix evenly to prepare solution B for later use;

[0032] Step 3, put solution A and solution B into a container, and mix and react for 2 ...

Embodiment 2

[0041] Embodiment 2: Taking 200g of the finished product of the electrode material as the meter, the molar percentages of the required raw materials are as follows: 120 g of ferrous chloride is selected as the metal salt containing iron ions, and the molar percentage is 25%, and the metal salt containing ferricyanide ions is sodium ferrocyanide 290g, the molar percentage is 25%, and the complexing agent is 252g of citric acid, and the molar percentage is 50%.

[0042] The synthesis method is as follows:

[0043] Step 1. According to the ratio of raw materials, take iron ion-containing metal salt and complexing agent into a container, add 10L solvent and mix evenly to become solution A for use;

[0044] Step 2, according to the ratio of raw materials, take metal salt containing ferricyanide ion and put it into a container, add 10L solvent and mix evenly to prepare solution B for later use;

[0045] Step 3, put solution A and solution B into a container, and mix and react for 4...

Embodiment 3

[0054] Embodiment 3: Taking 500g of the finished product of the electrode material as the meter, the molar percentages of the required raw materials are as follows: 300g of ferrous chloride is selected as the metal salt containing iron ions, and the molar percentage is 30%, and the metal salt containing ferricyanide ions is sodium ferrocyanide 725g, the molar percentage is 30%, and the complexing agent is 396g of sodium alginate, and the molar percentage is 40%.

[0055] The synthesis method is as follows:

[0056] Step 1. According to the ratio of raw materials, take iron ion-containing metal salt and complexing agent into a container, add 10L solvent and mix evenly to become solution A for use;

[0057] Step 2, according to the ratio of raw materials, take metal salt containing ferricyanide ion and put it into a container, add 10L solvent and mix evenly to prepare solution B for later use;

[0058] Step 3, put solution A and solution B into the container, and mix and react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com