Preparation method of nitrogen-doped carbon composite transition metal carbodiimide

A carbodiimide and transition metal technology, which is applied in the field of preparation of nitrogen-doped carbon composite transition metal carbodiimide materials, can solve the problems of high synthesis cost and complex synthesis steps, and achieves reduced preparation cost and simple preparation method. , the effect of improving electrical conductivity and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Fully grind analytically pure ferric citrate, ferric chloride and urea in a glass mortar to form a mixture A, wherein the ferric citrate is 2.0 g, the ferric chloride is 2.0 g, and the urea is 2.0 g;

[0032] 2) Transfer the mixture A from the mortar to a quartz crucible, place the quartz crucible in a tube furnace, and raise the temperature at a rate of 30°C / min to 170°C, and keep it warm for 50min, and then continue to raise the temperature to 600°C at a rate of 4°C / min under the argon flow rate of 200mL / min, and keep it warm for 45min to obtain product B.

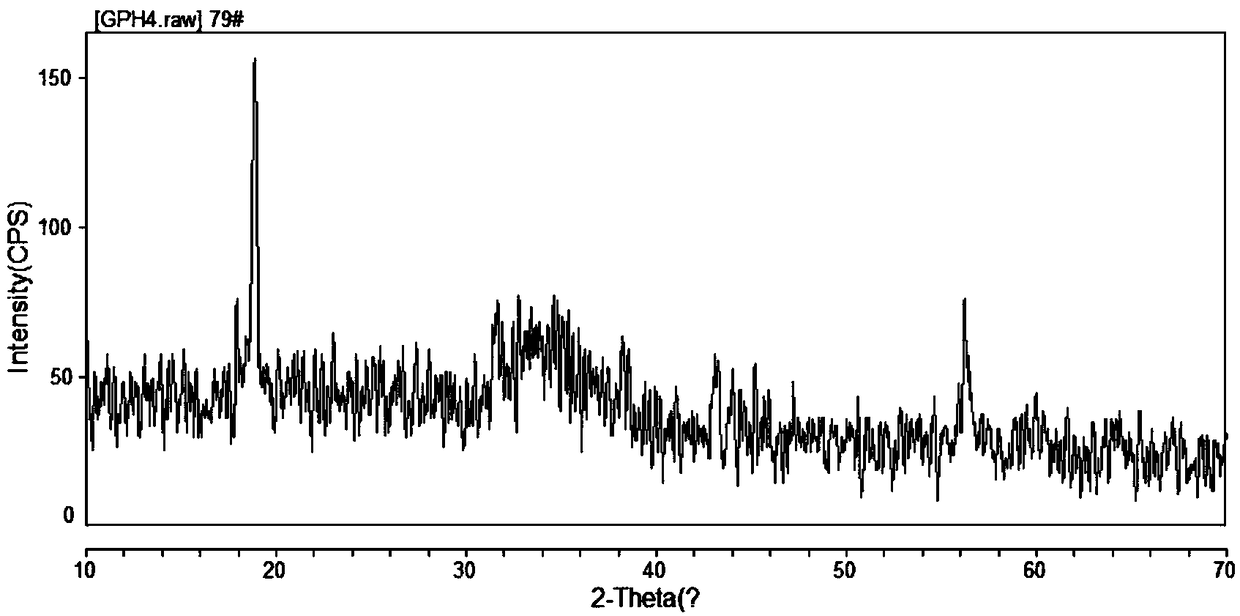

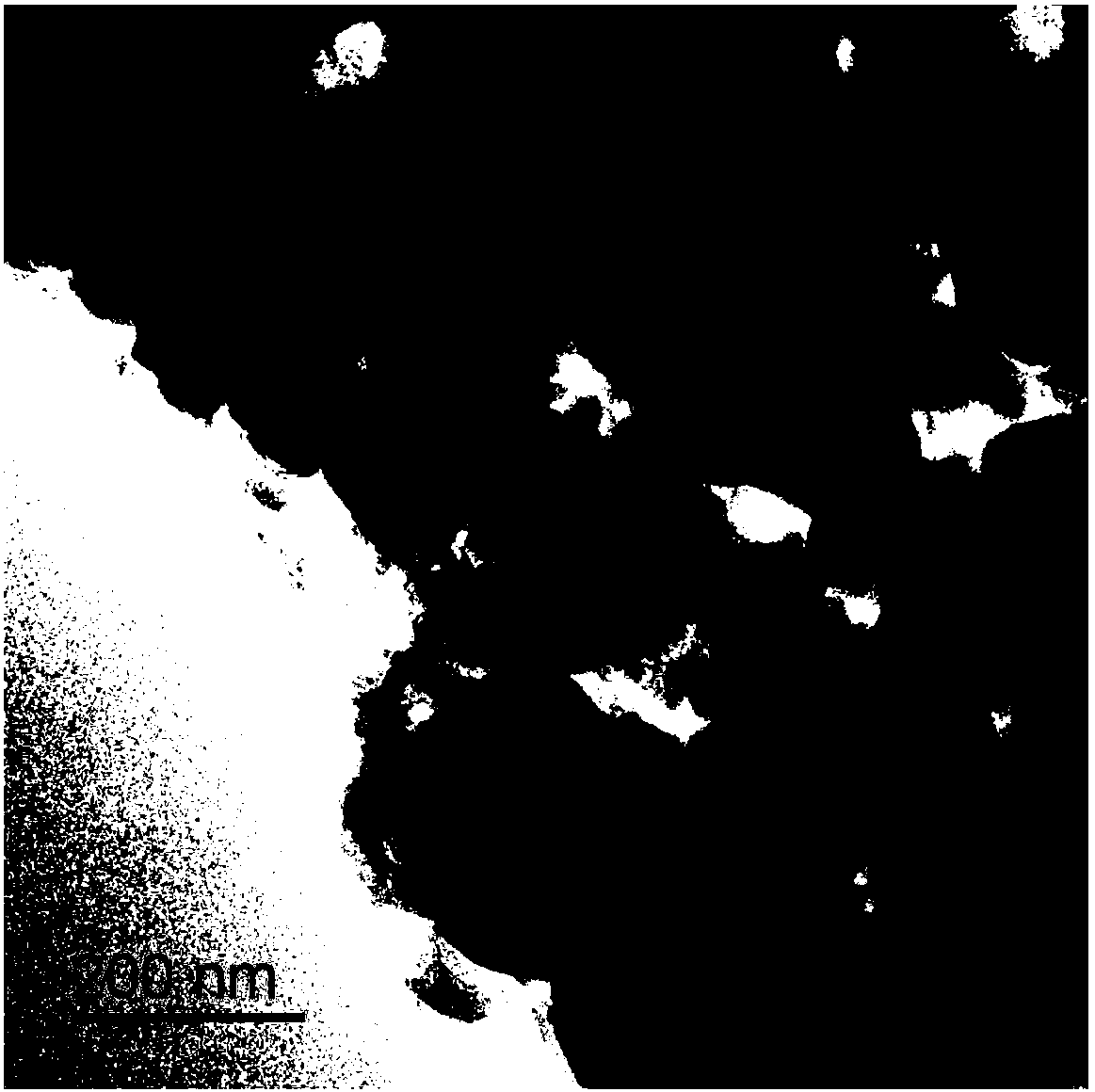

[0033] Adopt Japanese Rigaku D / max2000PCX-ray diffractometer to analyze product B, the XRD of the product obtained is shown in the appendix figure 1 . The sample was observed under scanning electron microscope and transmission electron microscope, from figure 2 and image 3 It can be seen from the figure that the product presents a shell-like structure, and the surface of the structure has more polyhedral s...

Embodiment 2

[0036] 1) Fully grind analytically pure cobalt oxalate, cobalt nitrate and thiocyanic acid in a glass mortar to form a mixture A, wherein 1 g of cobalt oxalate, 1 g of cobalt nitrate, and 2 g of thiocyanic acid;

[0037] 2) Transfer A from the mortar to a quartz crucible, place the quartz crucible in a tube furnace, and raise the temperature to 180 °C at a rate of 20 °C / min under an argon atmosphere at a flow rate of 750 mL / min ℃, and keep it warm for 8 minutes, and then continue to raise the temperature to 500 ℃ at a rate of 3 ℃ / min under the argon flow rate of 50mL / min, and keep it warm for 50 minutes, and the obtained product is marked as B.

[0038] Adopt Japanese Rigaku D / max2000PCX-ray diffractometer to analyze product B, the XRD of the product obtained is shown in the appendix Figure 5 . The sample was observed under scanning electron microscope and transmission electron microscope, from Image 6 and Figure 7 It can be seen that the product presents a stacked polyh...

Embodiment 3

[0040]1) Fully grind the inorganic transition metal salt and the carbon-nitrogen-containing organic compound in a glass mortar to obtain a mixture, and the mass ratio of the inorganic transition metal salt to the carbon-nitrogen-containing organic compound in the mixture is 4:1; wherein, the inorganic transition metal The salt is a mixture of ferric citrate and ferric nitrate. Carbon and nitrogen-containing organic compounds are biurets.

[0041] 2) Transfer the mixture from the mortar to a quartz crucible, place the quartz crucible in a tube furnace, and raise the temperature from room temperature at a rate of 5°C / min under an argon atmosphere with an argon flow rate of 1000mL / min To 200°C and keep it warm for 10min, then continue to raise the temperature to 700°C at a rate of 5°C / min under the argon flow rate of 100mL / min and keep it warm for 30min to obtain a nitrogen-doped carbon composite transition metal carbodiimide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com