High-sodium coal sodium removal, quality improvement fan mill pulverization and water recovery combined cycle power generation system

A combined cycle power generation and cycle power generation technology, applied in the field of coal power generation, can solve the problems of waste of heat energy and water resources, waste gas heat energy recovery and insufficient water recovery, and achieve the effects of safe operation, small investment, and improvement of corrosion problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

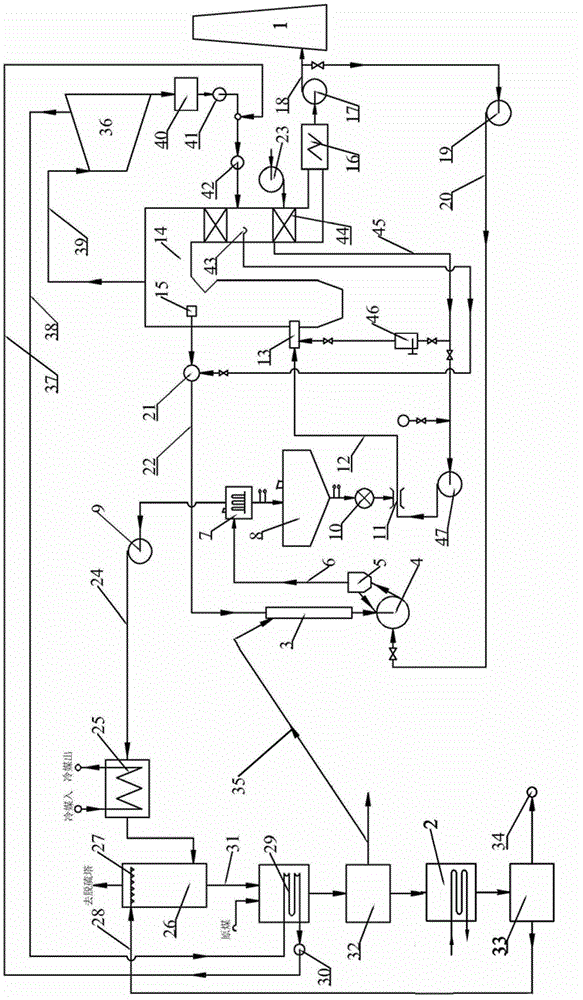

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

[0035] Such as figure 1 As shown, the labels respectively indicate: 1-desulfurization tower; 2-heat energy recovery device; 3-downward drying pipe; 4-fan coal mill; 5-coal powder separator; ;8-powdered coal bunker; 9-exhaust air fan; 10-powder feeder; 11-powder powder mixer; 12-powder feed pipeline; 13-powdered coal burner; 14-boiler; 16-dust collector; 17-induced fan; 18-flue; 19-cold smoke fan; 20-cold smoke pipe; 21-mixing chamber; 22-high temperature furnace smoke pipe; - Exhaust gas waste heat recovery device; 26- exhaust gas condensation recovery device; 27- sprinkler head; 28- cold water pipeline; 29- raw coal desodiumization device; Unit; 34-chemical plant; 35-coal handling device; 36-turbine; 37-drain pipe; 38-extraction pipe; 39-boiler main steam pipe; 40-condenser; 41-condensate pump; 42-feed water pump ; 43-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com