Sodium-removing purification cyclic system of high-sodium coal

A circulation system and high-sodium coal technology, applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of reducing the calorific value of coal-fired boilers in the service life of boilers, increasing construction investment and power plant operating costs, and achieving coking in the furnace. The effect of improving the pollution problem of the heating surface, small investment and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

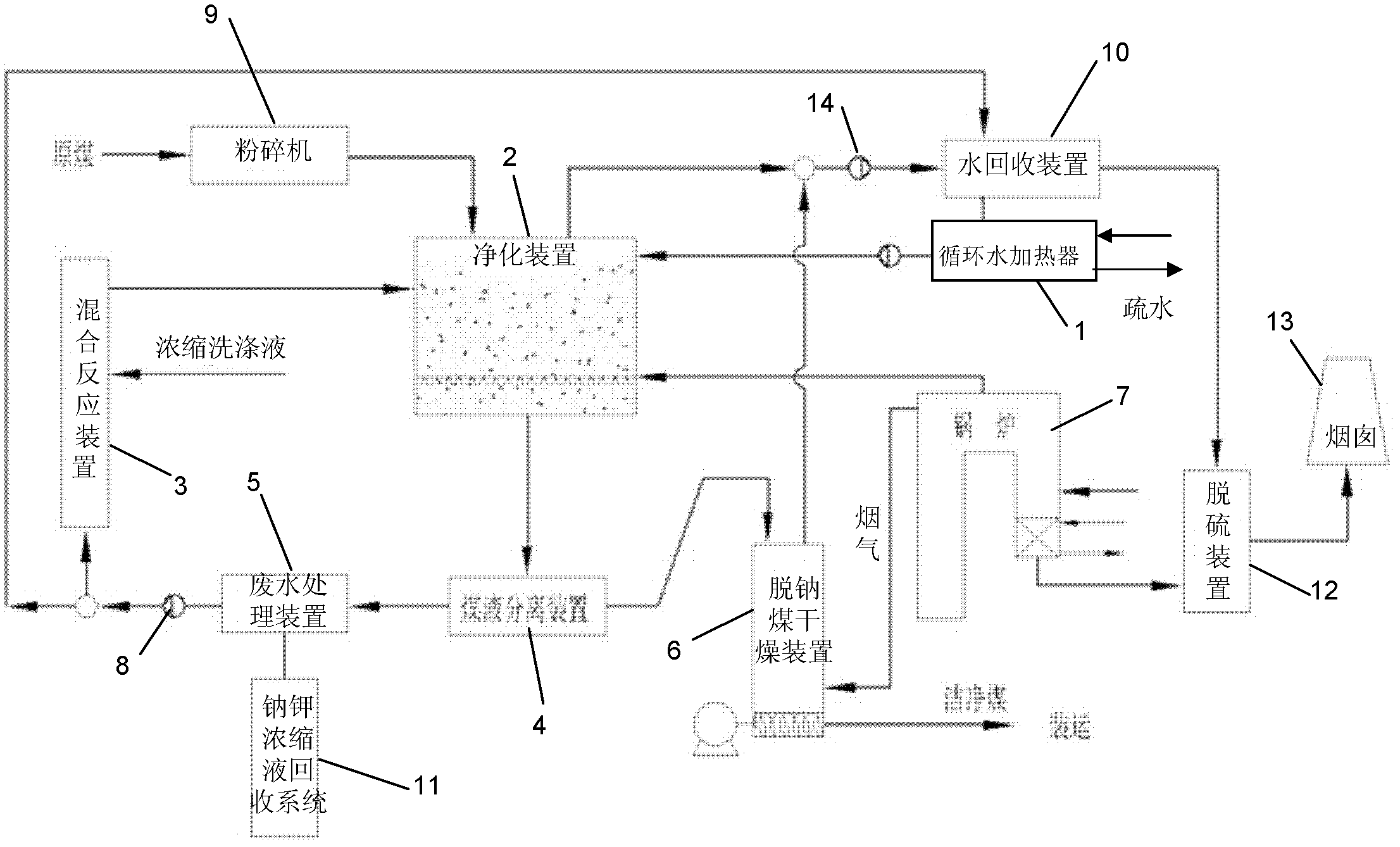

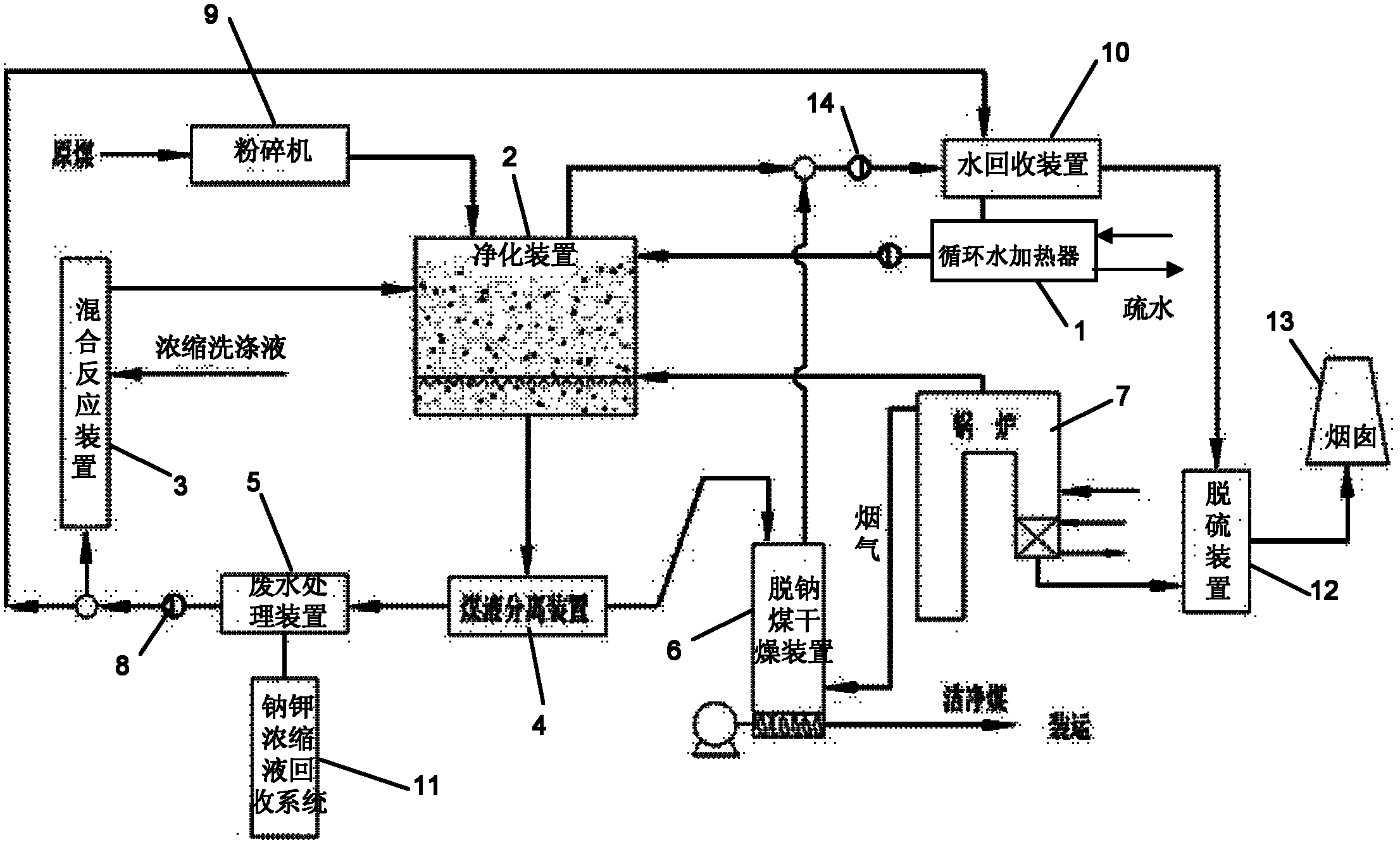

[0038] like figure 1 As shown, the high-sodium coal desodium purification circulation system of the present invention mainly includes a circulating water heater 1 connected by a circulation pipeline, a raw coal purification device 2, a mixing reaction device 3, a coal-liquid separation device 4, a waste water treatment device 5, a degassing Sodium coal drying device 6 and steam heating source 7, wherein, the input end of circulating water heater 1 receives circulating water and make-up water, and receives the extracted steam from steam heating source 7 to heat the water, and the output end of circulating water heater 1 is connected with raw coal purification The device 2 is connected; the input end of the raw coal purification device 2 receives the hot water output by the circulating water heater 1 and the pulverized high-sodium raw coal, and the washing liquid and steam are respectively input through the mixing reaction device 3 and the steam heating source 7, and the raw coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com