Eastern Junggar coal slagging and contamination improvement additive and application method thereof

An additive and slagging technology, which is applied in the field of additives to improve Zhundong coal slagging, additives, and pollution. It can solve the problems of boiler slagging and pollution, and achieve the effects of reducing slagging, enriching resources, and preventing aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

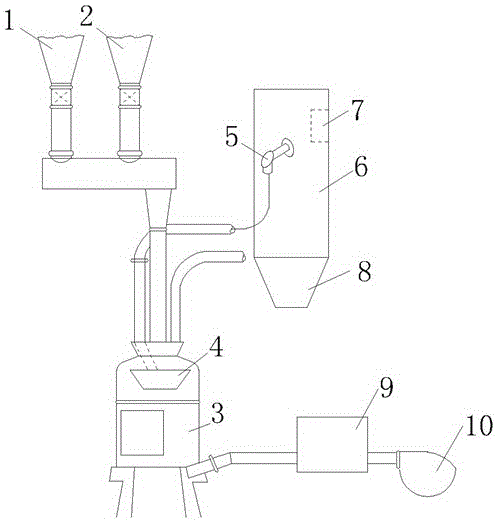

[0018] A settling furnace, comprising a roller coal mill 3, the roller coal mill 3 is connected with a pulverizer 1 and a feeder 2, and the medium-speed roller coal mill 3 is provided with A centrifugal separator 4 also includes a furnace 6, a slagging rod is arranged in the described furnace 6, a soot blower 7 is arranged on the side wall of the described furnace 6, and the bottom of the described furnace 6 is provided with An ash collector 8, a burner 5 is arranged in the furnace 6, and the medium-speed roller mill 3 is connected to the furnace 6 through at least one first pipeline, and the first pipeline One end is connected to the centrifugal separator 4, the roller mill 3 is connected to a fan 10 through a second pipeline, and an air preheater 9 is arranged on the second pipeline.

[0019] The settling furnace adopts a two-stage heating method to simulate the combustion condition. The pulverized coal and additives are fully mixed in the coal mill. The mixture of powder a...

Embodiment 2

[0022] A method for testing the slagging properties of coal species and the volatility of sodium and sulfur in a sinking furnace, specifically comprising the following steps:

[0023] (1) Take coal from Dongshaer Lake and put it into a coal mill to grind to R after drying 90 =35%, enter the furnace through the powder feeder for combustion, the powder feed rate is 8g / min, the excess air coefficient is 1.2, the temperature conditions are set to 900°C, 1000°C, 1100°C respectively, and the burnout rate reaches more than 97%.

[0024] (2) There is a slagging rod in the furnace, which is installed in the constant temperature zone. It is a tubular curved surface structure, which simulates the flue gas erosion conditions, and can be taken out regularly to observe the slagging and contamination. There is a water-cooled ash collection system at the bottom of the furnace to collect the bottom ash.

[0025] (3) Analyze the thickness, hardness and viscosity of the slag layer on the slaggi...

Embodiment 3

[0028] A method for testing the slagging properties of coal species and the volatility of sodium and sulfur in a sinking furnace, specifically comprising the following steps:

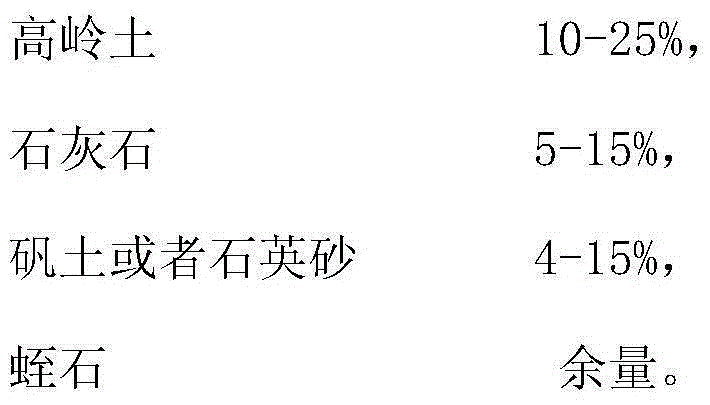

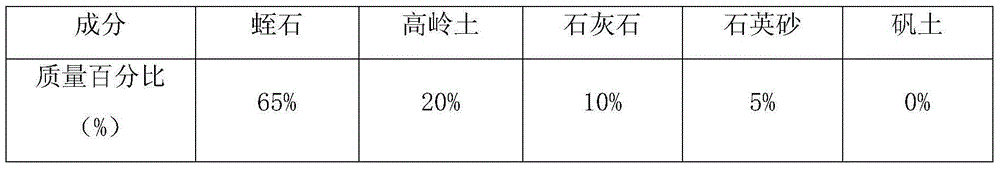

[0029] (1) Configure additives according to the ratio in the table below:

[0030]

[0031] (2) Take the coal from Dongshaer Lake and put it into the coal mill to grind to R after drying 90 =35%, grind the additive until the maximum particle size does not exceed 150mm, put the ground additive and coal powder into the mixer at a mass ratio of 0.1:1 and mix them thoroughly, and put the mixture into the furnace through the powder feeder for combustion , the powder feeding amount is 8g / min, the excess air coefficient is 1.2, the temperature conditions are set to 900°C, 1000°C, and 1100°C respectively, and the burnout rate reaches more than 97%.

[0032] (3) There is a slagging rod in the furnace, which is installed in the constant temperature zone. It is a tubular curved surface structure, which simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com