Additive for inhibiting alkali metal release in Zhundong high-sodium coal combustion and realization method thereof

A realization method and additive technology, applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve problems that have not been reported, less research on actual control methods, and stay at the level of theoretical research, so as to ensure safe operation and solve slagging Corrosion problems, the effect of inhibiting the release of alkali metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The embodiment of the present invention provides an additive for inhibiting the release of alkali metals in Zhundong high-sodium coal combustion. The components in the additive and their corresponding mass percentages are as follows:

[0027]

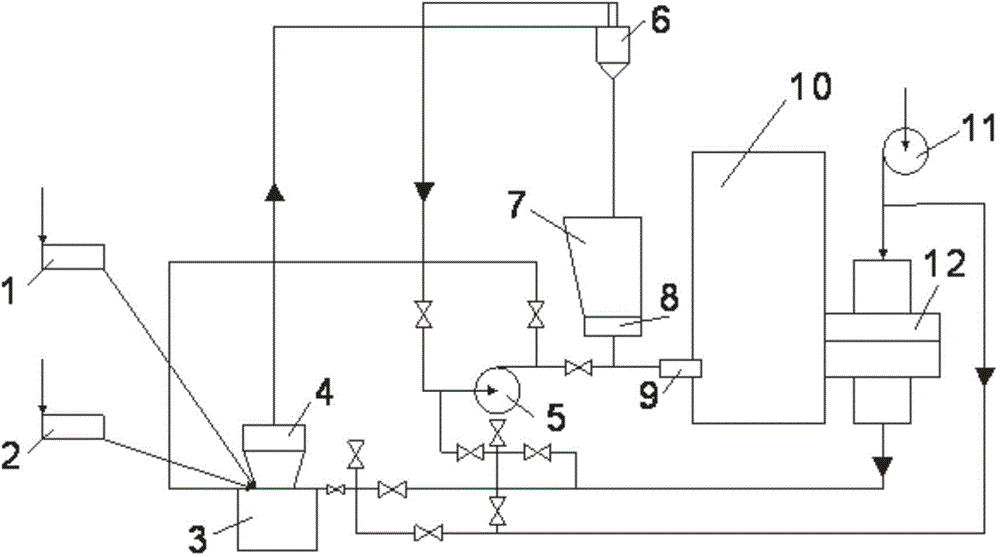

[0028] figure 1 It shows the additive blending treatment method of the intermediate storage type pulverized coal combustion system according to Embodiment 1 of the present invention. In this embodiment, it is only necessary to add an additive feeding system and its associated additive storage bin to the mid-storage pulverizing system operated by the existing power station.

[0029] The working process is described below: firstly, the additive feeding amount is determined according to the coal feeding amount and the blending mass fraction of 0.5%. When the coal feeder 2 performs the coal feeding operation to the coal mill 3, the additive feeder 1 simultaneously performs the feeding operation. The raw coal and additives are cr...

Embodiment 2

[0031] The embodiment of the present invention provides an additive for inhibiting the release of alkali metals in Zhundong high-sodium coal combustion. The components in the additive and their corresponding mass percentages are as follows:

[0032]

[0033]

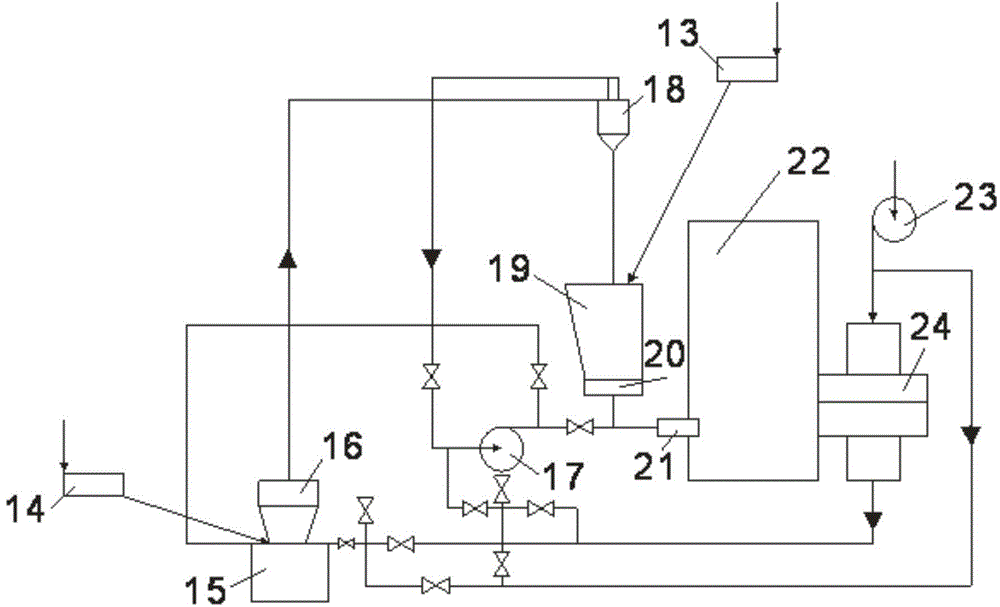

[0034] figure 2 It shows the additive blending treatment method of the intermediate storage type pulverized coal combustion system according to Embodiment 2 of the present invention. In this embodiment, it is only necessary to add an additive crushing system and its supporting storage bins, feeding systems, etc. to the mid-storage pulverizing system operated by the existing power station.

[0035] The working process is described below: firstly, the additive feeding amount is determined according to the coal feeding amount and the blending mass fraction of 1%, and the additive is ground to the fineness of the existing coal powder through the crushing system in advance (R90=5~30%) ); when the coal feeder 14 carrie...

Embodiment 3

[0037] The embodiment of the present invention provides an additive for inhibiting the release of alkali metals in Zhundong high-sodium coal combustion. The components in the additive and their corresponding mass percentages are as follows:

[0038]

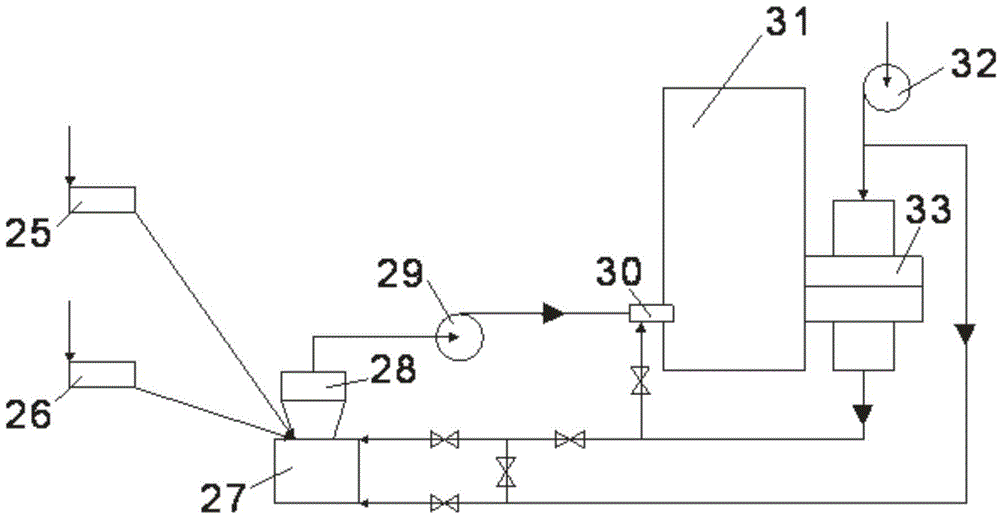

[0039] image 3 It shows the additive blending treatment method of the direct blowing pulverized coal combustion system according to Embodiment 3 of the present invention. In this embodiment, it is only necessary to add an additive feeding system and its associated additive storage bins to the direct-blown pulverizing system operating in the existing power station.

[0040] The working process is described below: firstly, the additive feeding amount is determined according to the coal feeding amount and the blending mass fraction of 3%. When the coal feeder 26 performs the coal feeding operation to the coal mill 27, the additive feeder 25 simultaneously performs the feeding operation. Raw coal and additives are crushed and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com