Ice cream composition and preparation method thereof

A composition and ice cream technology, applied in the fields of frozen desserts, food science, food heat treatment, etc., can solve the problems of easy rapid melting, affecting consumers' experience of ice cream, low sliding melting point, etc., and achieve excellent melting characteristics, good emulsification effect, reduce oozing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Mix 67.5% water, 9% skim milk powder, 11% xylitol, 2% sweetener syrup, 0.2% stabilizer mixture using a mixer at room temperature for 10-20 minutes; add fully melted 10% after fractionation Soybean oil-based diglyceride, then add 0.3% vanilla extract; pasteurize by heating at 80°C for 20 minutes; homogenize the mixture for 12 minutes through a homogenizer (7000rpm / min); age in a refrigerator at 4°C for 6 hours ; The aged ice cream was frozen by freezing (-4° C.) for 15 minutes.

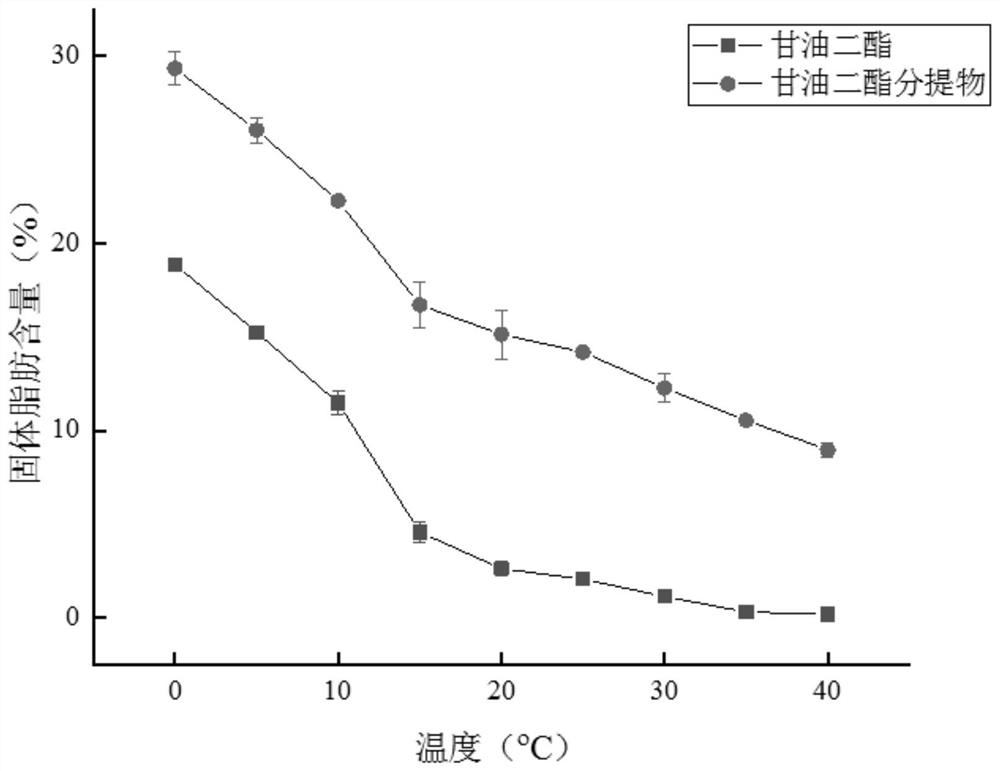

[0075] The prepared ice cream has a good taste without any foreign body sensation, and the intake of the ice cream can make people feel satisfied without increasing the risk of obesity. At this time, the sliding melting point of the ice cream is 32.1°C, which can better solve the problem of high-temperature facilitation of the ice cream, and can maintain a good taste after leaving the refrigerator for a long time.

Embodiment 2

[0077] Mix 71.5% water, 9% skimmed milk powder, 11% xylitol, 2% sweetener syrup, 0.2% stabilizer mixture using a mixer at room temperature for 10-20 minutes; add fully melted 6% after fractionation Soybean oil-based diglyceride, then add 0.3% vanilla extract; heat at 80°C for 20 minutes to pasteurize; the mixture is homogenized by a homogenizer (7000rpm / min) for 12 minutes; age in a refrigerator at 4°C for 6 hours; The aged ice cream was frozen by freezing (-4°C) for 15 minutes.

[0078] The prepared ice cream has a better mouthfeel and no foreign body sensation, but the richness of the mouthfeel is significantly reduced (compared to Example 1), and the sliding melting point is 29.8°C, which still has good resistance to high melting, but it is easier to melt than Example 1. Melting, and the level of taste is reduced.

Embodiment 3

[0080] Mix 62.5% water, 9% skimmed milk powder, 11% xylitol, 2% sweetener syrup, 0.2% stabilizer mixture using a mixer at room temperature for 10-20 minutes; add fully melted 15% after fractionation Soybean oil-based diglyceride, then add 0.3% vanilla extract; heat at 80°C for 20 minutes to pasteurize; the mixture is homogenized by a homogenizer (7000rpm / min) for 12 minutes; age in a refrigerator at 4°C for 6 hours; The aged ice cream was frozen by freezing (-4°C) for 15 minutes.

[0081] The prepared ice cream has a good taste, with a sliding melting point of 34.1°C, which is relatively high. During the short residence time in the mouth, a small part of the ice cream will not be able to melt, resulting in a certain sandy feeling, but to a lesser extent, there are still better acceptance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com