Method for removing sodium in preparation of high-purity alumina

A high-purity alumina and preparation process technology is applied in the field of high-purity material preparation, and achieves the effects of obvious sodium removal effect, simple use process and no pollution in use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

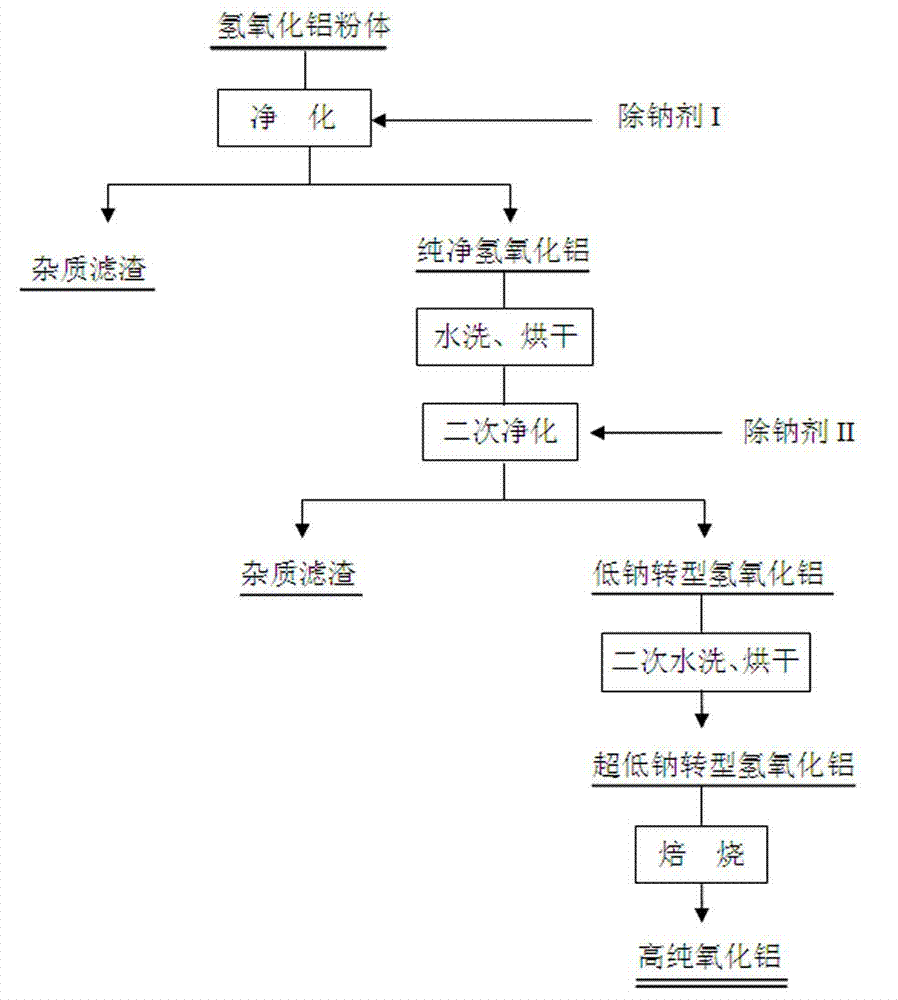

Method used

Image

Examples

Embodiment 1

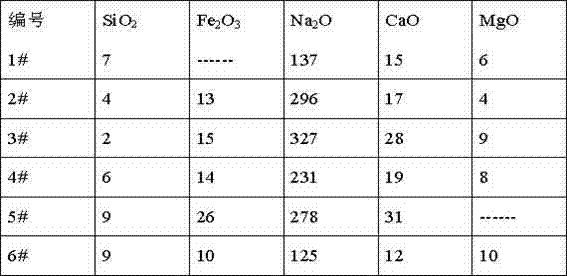

[0027] Take 1# aluminum hydroxide powder with an initial sodium content of 137ppm and grind it to ≤500μm for later use; wash the finely ground aluminum hydroxide powder with 45g / L hydrochloric acid in a constant temperature water bath at 50-55°C for 2-3 times to obtain pure Aluminum hydroxide; wash the purified aluminum hydroxide to pH7.0~7.5, dry and dehydrate at 300°C; add 10g / L ammonium chloride to the washed and dried aluminum hydroxide at 30~50 Stir and wash in a constant temperature water bath at ℃ for 2 to 3 times for secondary purification; wash the aluminum hydroxide after secondary purification with pure water at 30 to 50 ℃, dry and dehydrate at 300 ℃ after washing, and transform it into a fluffy ultra-low sodium Aluminum hydroxide, the sodium content is 9ppm after testing.

Embodiment 2

[0029] Take 2# aluminum hydroxide powder with an initial sodium content of 296ppm and grind it to ≤500μm for later use; wash the finely ground aluminum hydroxide powder with 35g / L hydrochloric acid in a constant temperature water bath at 50-55°C for 2-3 times to obtain pure Aluminum hydroxide; wash the purified aluminum hydroxide to pH 7.0-7.5, dry and dehydrate at 350°C; add 15g / L ammonium carbonate to the washed and dried aluminum hydroxide at 30-50°C Stir and wash in a constant temperature water bath for 2 to 3 times for secondary purification; wash the aluminum hydroxide after secondary purification with pure water at 30 to 50°C, dry and dehydrate at 500°C after washing, and transform it into a fluffy ultra-low sodium hydroxide Aluminum, tested sodium content is 8ppm.

Embodiment 3

[0031] Take 3# aluminum hydroxide powder with an initial sodium content of 327ppm and grind it to ≤500μm for later use; wash the finely ground aluminum hydroxide powder with 35g / L hydrochloric acid in a constant temperature water bath at 50-55°C for 2-3 times to obtain pure Aluminum hydroxide; wash the purified aluminum hydroxide to pH 7.0-7.5, dry and dehydrate at 500°C; add 15g / L ammonium carbonate to the washed and dried aluminum hydroxide at 30-50°C Stir and wash in a constant temperature water bath for 2 to 3 times for secondary purification; wash the aluminum hydroxide after secondary purification with pure water at 30 to 50°C, dry and dehydrate at 500°C after washing, and transform it into a fluffy ultra-low sodium hydroxide Aluminum, tested sodium content is 7ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com