Alkali-free non-nitrite concrete reinforcement antirust

A technology of concrete reinforcement and nitrite, applied in the field of reinforcement rust inhibitor, can solve problems such as accelerating reinforcement corrosion, and achieve the effects of inhibiting reinforcement corrosion and inhibiting anodic and cathodic reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of concrete steel bar rust inhibitor, the optimal combined weight percent of each constituent is:

[0026] Zinc gluconate 5%, lithium silicate 30%, ammonium benzoate 15%, low molecular weight (alcohol) amines 20%, water 30%.

[0027] The test items and methods refer to "Reinforced Concrete Corrosion Inhibitor" (JT / T 537-2004).

Embodiment 2

[0028] Embodiment 2: a kind of concrete reinforcement rust inhibitor, the percentage by weight of each constituent is: zinc gluconate 3%, lithium silicate 35%, ammonium benzoate 10%, low molecular weight (alcohol) amines 25%, water 27% %.

[0029] The test items and methods refer to "Reinforced Concrete Corrosion Inhibitor" (JT / T 537-2004).

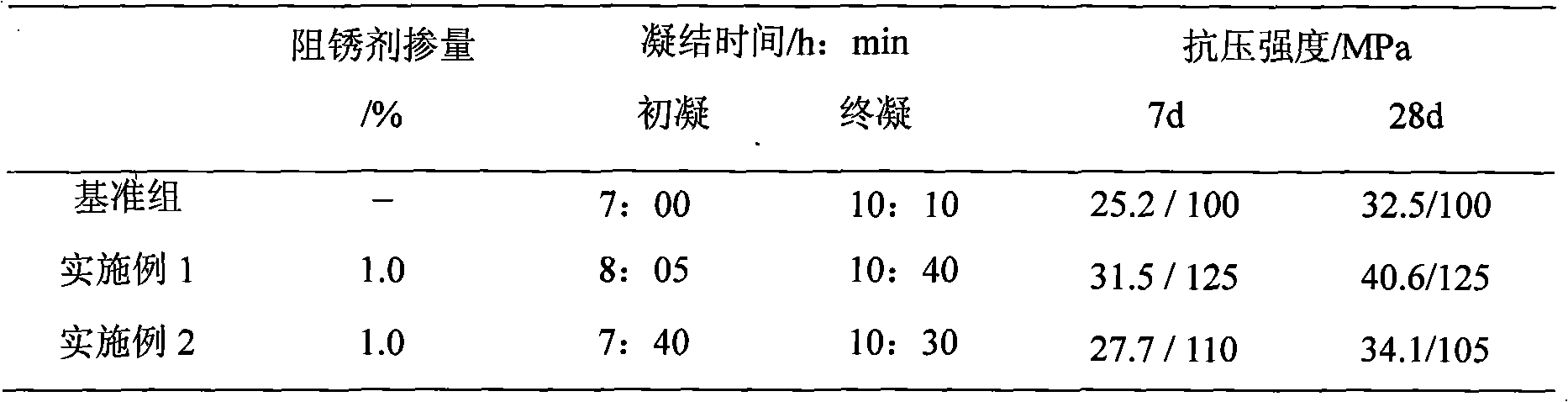

[0030] The technical performance of concrete after adding rust inhibitor is shown in Table 1.

[0031] As can be seen from Table 1, the present invention has a certain water-reducing effect, can significantly improve the 7d and 28d compressive strength of concrete; and has a certain retarding effect on concrete. It meets the requirements of the specification "Reinforced Concrete Rust Inhibitor" (JT / T 537-2004).

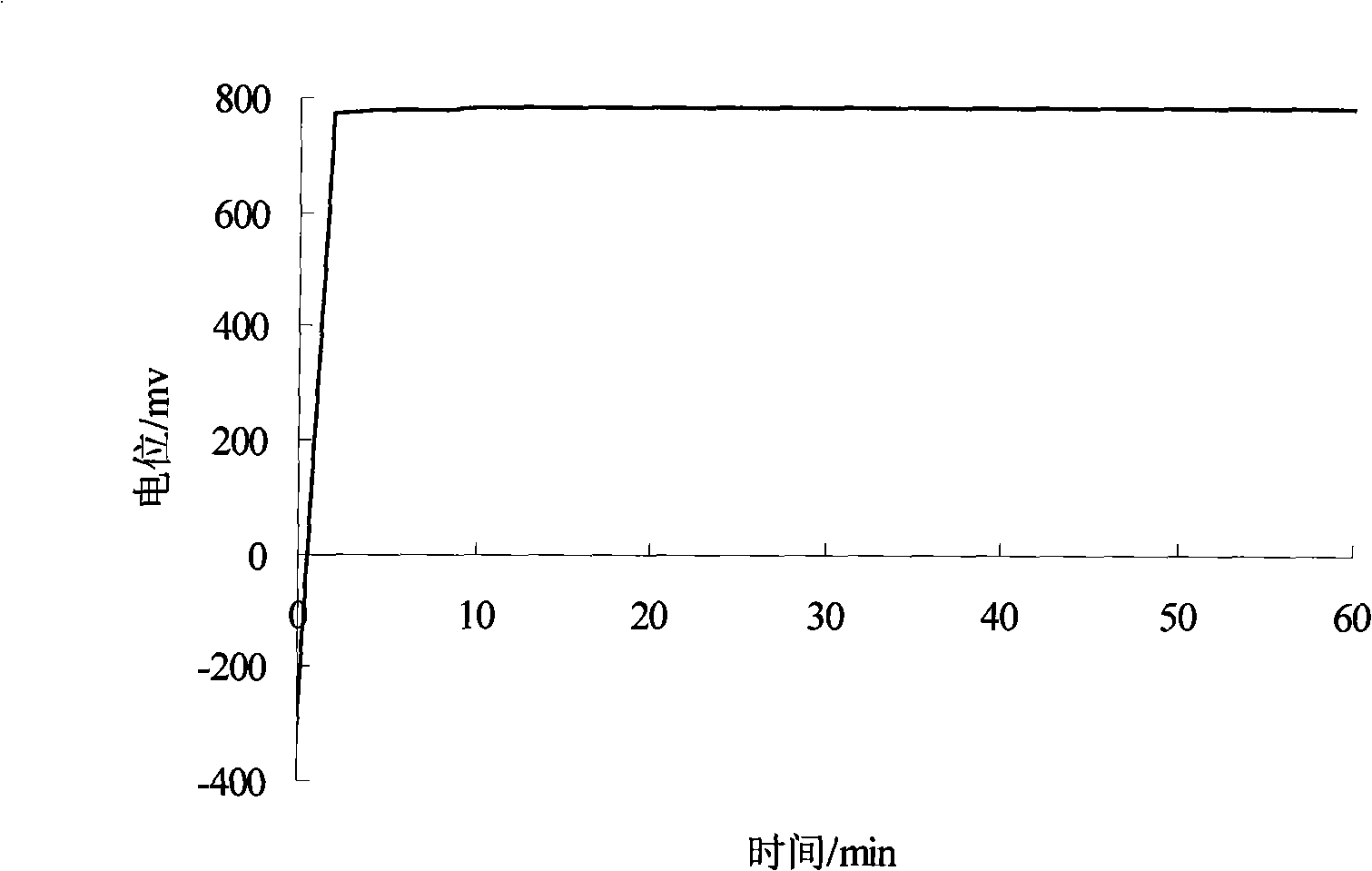

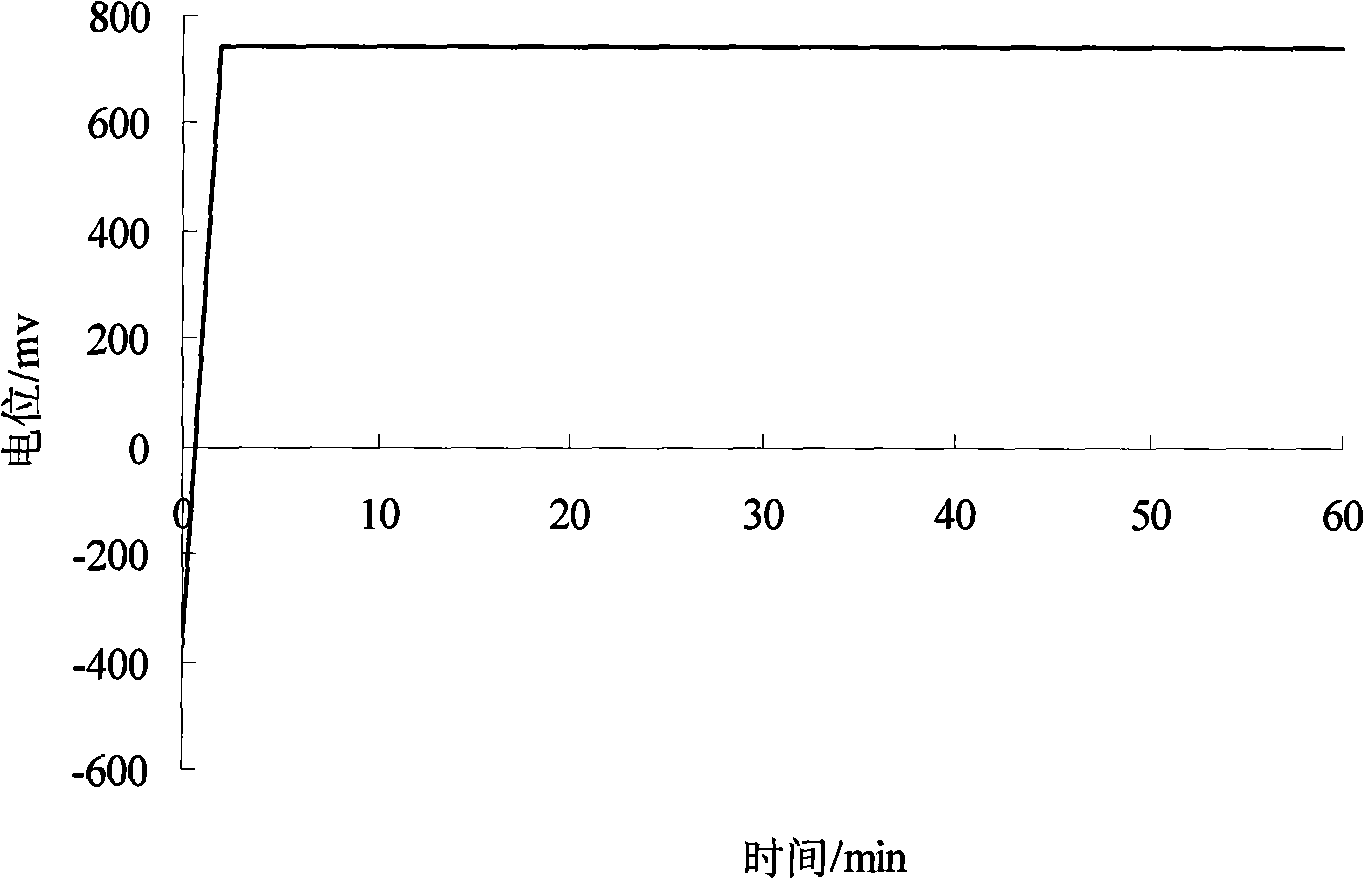

[0032] figure 1 and figure 2 The results of constant current and potential-time curve analysis diagrams show that the present invention has no corrosion effect on steel bars.

[0033] Table 1 Concrete technical performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com