A kind of cement-based concrete waterproof coating and its preparation and application method

A waterproof coating and concrete technology, applied in building insulation materials, building components, buildings, etc., can solve problems such as poor weather resistance, strong toxicity, and incompatible interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

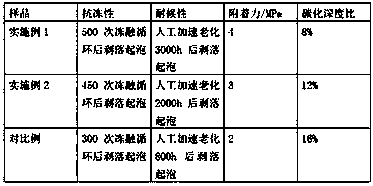

Examples

Embodiment 1

[0027] A cement-based concrete waterproof coating, in parts by weight, comprising the following substances and parts by weight: 1.4 parts of sodium nitrate, 2.5 parts of sodium carbonate, 3 parts of sodium sulfate, 0.1 part of calcium chloride, 0.9 part of calcium carbide, 0.9 part of lime, 38.2 parts of cement, 44 parts of sand, and 9 parts of water.

[0028] A preparation method of cement-based concrete waterproof coating, comprising the following steps:

[0029] (1) Preparation of sodium nitrate, sodium carbonate, sodium sulfate and calcium chloride, put sodium nitrate, sodium carbonate, sodium sulfate and calcium chloride in an oven for drying treatment, detect their moisture content, make sodium nitrate, The moisture content of sodium, sodium sulfate and calcium chloride is controlled within 4.5%;

[0030] (2) Calcium carbide preparation. Calcium carbide particles are rolled and crushed to a particle size of 0.2mm, then placed in an oven for drying treatment, and the moi...

Embodiment 2

[0039] The preparation and use method of a kind of cement-based concrete waterproof coating in the present embodiment are the same, and wherein the technical parameters are different:

[0040] This cement-based concrete waterproof coating comprises the following materials and parts by weight in parts by weight: 0.9 part of sodium nitrate, 2 parts of sodium carbonate, 2.5 parts of sodium sulfate, 0.05 part of calcium chloride, 0.75 part of calcium carbide, 0.8 part of lime, 36 parts of cement, 39 parts of sand, and 8 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com