A multifunctional admixture for improving concrete strength, efficiently inhibiting chloride ion diffusion and steel bar corrosion and preparation method thereof

A technology for chloride ion diffusion and concrete strength, applied in chemical instruments and methods, nanotechnology for materials and surface science, silicon compounds, etc. Solve problems such as singleness, achieve the effect of improving the low utilization rate of functions, inhibiting the corrosion of steel bars, and improving the level of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

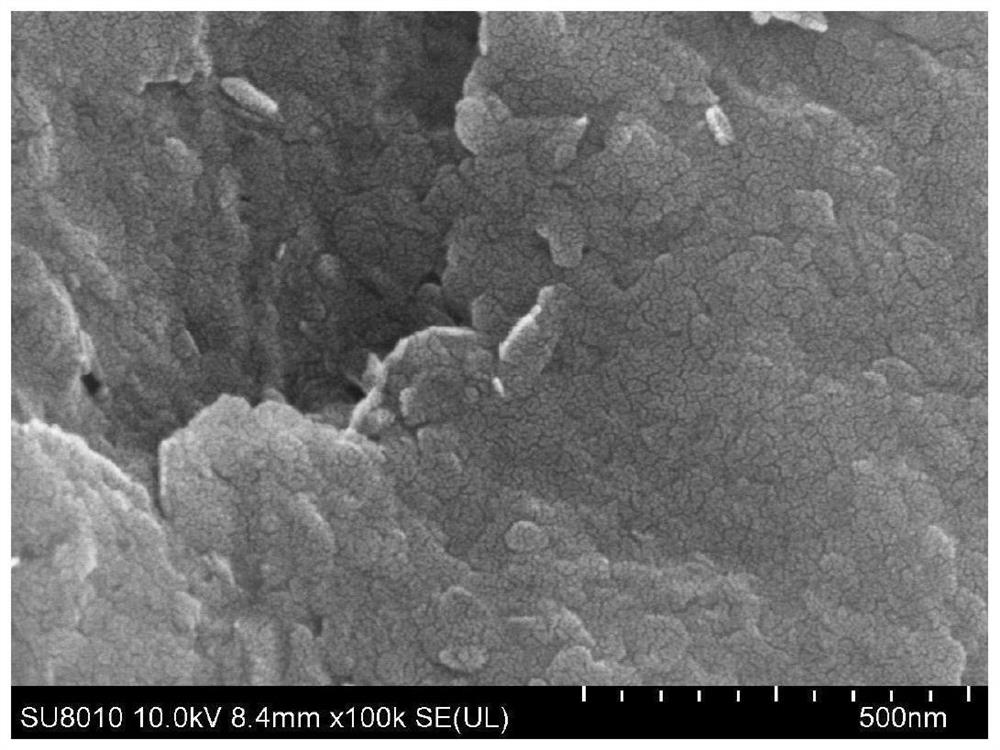

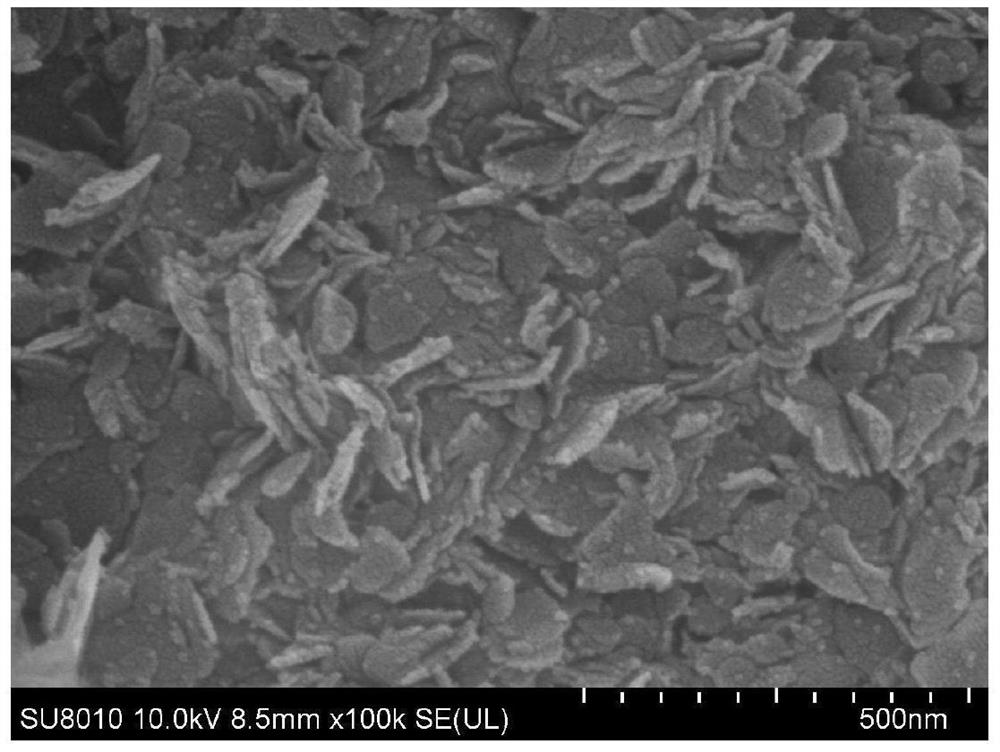

[0034] Dissolve 7.3g of octane and 0.146g of L-lysine in 280ml of distilled water and stir at 60°C for 1h; then add 4g of tetraethyl orthosilicate and stir at 60°C for 4h to obtain nano Silica solution. 6.83g of NaNO 2 Dissolve in 200ml distilled water to form B liquid, 34.18gMg(NO 3 ) 2 ·6H 2 O, 25g Al(NO 3 ) 3 9H 2 O (Mg / Al molar ratio equal to 2) was dissolved in 200ml of distilled water to form A liquid. Add solution A to solution B dropwise, use 2 mol / l NaOH to maintain the pH at around 10, and stir at 25°C for 1 hour. Then keep the temperature at 60°C for 15 hours in a water bath, wash with distilled water three times, and dry in vacuum for 15 hours to obtain layered Mg-Al double hydroxides (LDHs) synthesized by co-deposition method. Grind 1.12 g of the prepared layered Mg-Al double metal hydroxide into powder, dissolve it in 280 ml of distilled water and ultrasonicate for 20 minutes, then add it dropwise to the synthesized nano-silica solution, and maintain it w...

Embodiment 2

[0037] Dissolve 7.3g of octane and 0.146g of L-lysine in 280ml of distilled water and stir at 60°C for 3h; then add 4g of tetraethyl orthosilicate and stir at 60°C for 6h to obtain nano Silica solution. 6.83g of NaNO 2 Dissolved in 200ml distilled water to form B solution, 34.18g Mg(NO 3 ) 2 ·6H 2 O, 16.69gAl(NO 3 ) 3 9H 2 O (Mg / Al molar ratio equal to 3) was dissolved in 200ml of distilled water to form A solution. Add solution A to solution B dropwise, use 2mol / l NaOH to maintain the pH value at about 10, and stir at 25°C for 3h. Then keep the temperature at 80° C. for 20 h in a water bath, wash with distilled water for 5 times, and dry in vacuum for 24 h to obtain layered Mg-Al double hydroxides (LDHs) synthesized by co-deposition method. Grind 1.12 g of the prepared layered Mg-Al double metal hydroxide into powder, dissolve it in 280 ml of distilled water and ultrasonicate for 50 min, then add it dropwise to the synthesized nano-silica solution, and maintain it wit...

Embodiment 3

[0040] Dissolve 7.3g of octane and 0.146g of L-lysine in 280ml of distilled water and stir at 60°C for 2h; then add 4g of tetraethyl orthosilicate and stir at 60°C for 5h to obtain nano Silica solution. 6.83g of NaNO 2 Dissolved in 200ml distilled water to form B solution, 34.18g of Mg(NO 3 ) 2 ·6H 2 O, 20.03g Al(NO 3 ) 3 9H 2 O (Mg / Al molar ratio equal to 2.5) was dissolved in 200ml of distilled water to form A solution. Add solution A to solution B dropwise, use 2 mol / l NaOH to maintain the pH at about 10, and stir at 25°C for 2 hours. Then keep the temperature in a water bath at 70°C for 16 hours, wash with distilled water for 4 times, and dry in vacuum for 20 hours to obtain layered Mg-Al double hydroxides (LDHs) synthesized by co-deposition method. Grind 1.12 g of the prepared layered Mg-Al double metal hydroxide into powder, dissolve it in 280 ml of distilled water and ultrasonicate for 40 minutes, then add it dropwise to the synthesized nano-silica solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com