Brewing technology of cherry tomato vinegar

A technique of cherry tomatoes and saintess, applied in the field of utilization and processing of cherry tomatoes, can solve the problems of low utilization rate of raw materials, inability to make full use of cherry tomatoes, unfavorable acetic acid brewing process fermentation process, etc., so as to prevent deterioration and improve The effect of slow fermentation process at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

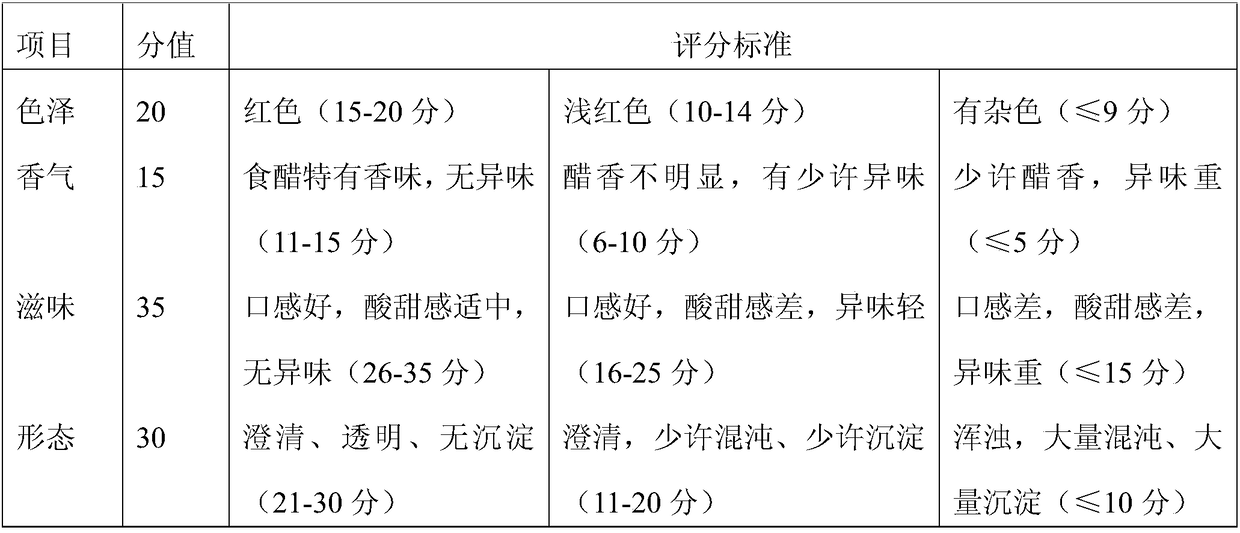

Image

Examples

Embodiment 1

[0024] A brewing process of cherry tomato vinegar, comprising the following steps:

[0025] (1) Drying and crushing treatment of cherry tomatoes: wash the cherry tomatoes, place them in infrared drying equipment, and dry them for 30 hours at 50°C, control the water content of the dried tomatoes to 15%, and then place them in a cyclone In the type ultrafine pulverizer, with 3000r / min to 50 μ m, obtain cherry tomato powder, standby;

[0026] (2) Freezing treatment: put the cherry tomato powder into the freezer, and freeze it for 24 hours at a freezing temperature of -18°C, take it out and thaw it, and obtain a cooling liquid;

[0027] (3) Enzymolysis: put 100 parts of cooling liquid and 0.2 part of cellulase into an enzymolyzer by weight, mix well, adjust the temperature to 40° C. and treat for 2 hours to obtain an enzymolysis solution;

[0028] (4) Component adjustment: measure the composition of the enzymolysis solution and adjust the reducing sugar>4.5% with sucrose, then ad...

Embodiment 2

[0034] A brewing process of cherry tomato vinegar, comprising the following steps:

[0035] (1) Drying and crushing treatment of cherry tomatoes: wash the cherry tomatoes, place them in infrared drying equipment, and dry them for 31 hours at 52°C, control the moisture content of the dried tomatoes to be 16%, and then place them in a cyclone In the type ultrafine pulverizer, pulverize to 70 μ m with 3200r / min, obtain cherry tomato powder, standby;

[0036] (2) Freezing treatment: put the cherry tomato powder into a freezer, freeze for 26 hours at a freezing temperature of -18°C, take it out and thaw it, and obtain a cooling liquid;

[0037] (3) Enzymolysis: put 100 parts of cooling liquid and 0.3 part of cellulase into the enzymolyzer, mix them evenly, and adjust the temperature to 45°C for 2.5 hours to obtain the enzymolysis solution;

[0038] (4) Component adjustment: measure the composition of the enzymolysis solution and adjust the reducing sugar>4.5% with sucrose, then us...

Embodiment 3

[0044] A brewing process of cherry tomato vinegar, comprising the following steps:

[0045](1) Drying and pulverizing treatment of cherry tomatoes: wash the cherry tomatoes, place them in infrared drying equipment, and dry them for 33 hours at 54°C, control the moisture content of the dried tomatoes to be 17%, and then place them in a cyclone In the type ultrafine pulverizer, pulverize to 80 μ m with 3600r / min, obtain cherry tomato powder, standby;

[0046] (2) Freezing treatment: put the cherry tomato powder into the freezer, freeze for 29 hours at a freezing temperature of -18°C, take it out and thaw it, and obtain a cooling liquid;

[0047] (3) Enzymolysis: put 100 parts of cooling liquid and 0.4 part of cellulase into the enzymolyzer by weight, mix well, adjust the temperature to 44°C for 3 hours, and obtain the enzymolysis solution;

[0048] (4) Component adjustment: measure the composition of the enzymolysis solution and adjust the reducing sugar>4.5% with sucrose, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com