Proton exchange method and equipment for producing lithium niobate light waveguide

A technology of proton exchange and lithium niobate, applied in optics, nonlinear optics, instruments, etc., can solve the problems of Li atom loss, large exchange capacity, and fast exchange reaction speed, so as to reduce lithium ion exchange capacity and reaction speed , the effect of reducing waveguide defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

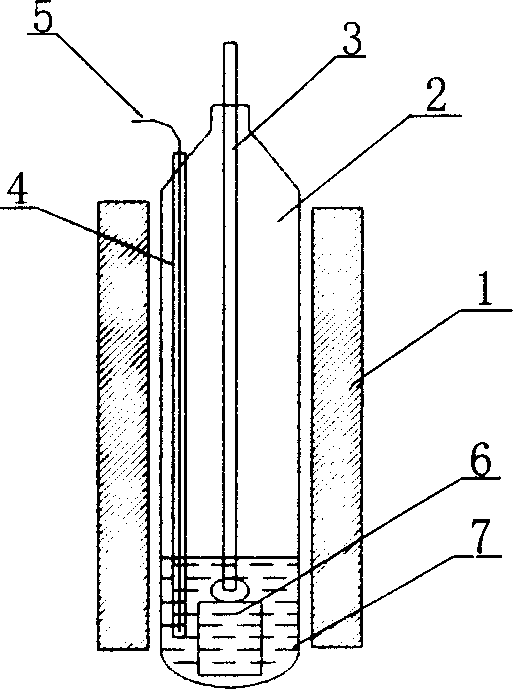

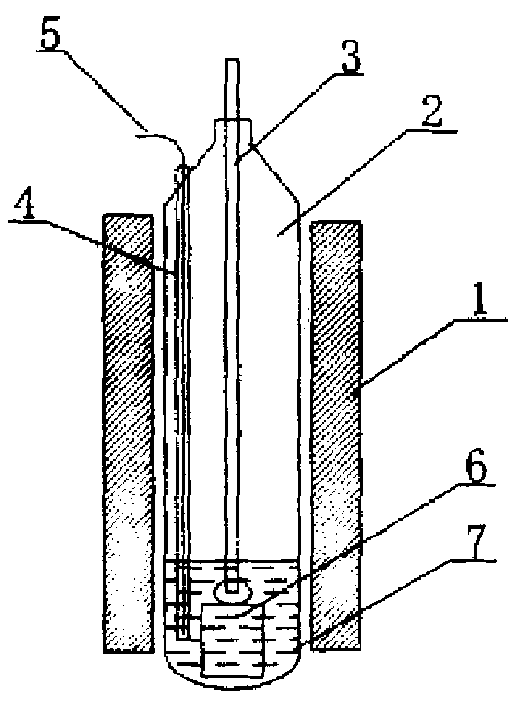

[0037] Such as figure 1 As shown, the proton exchange device of the present invention comprises:

[0038] Heating furnace 1;

[0039] Quartz pipeline 2 for containing benzoic acid mixed solution 7;

[0040] A quartz fixture 6 for loading a lithium niobate substrate;

[0041] A temperature measuring tube 4 and a thermocouple 5 for monitoring the temperature;

[0042] Wherein the quartz pipeline 2 is nested in the heating furnace 1, and the quartz clamp 6 is inserted into the benzoic acid mixed solution 7 of the quartz pipeline 2 through the quartz pull rod 3; the thermocouple 5 is inserted into the temperature measuring tube 4, and the temperature measuring tube 4 is located at In the quartz pipeline 2, its lower end is positioned in the benzoic acid mixed solution 7.

[0043] The complete method for manufacturing lithium niobate optical waveguide by proton exchange in the present invention includes preparation of polished substrate, cleaning of substrate, preparation of ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com