Preparation method of multi-component organic cross-linked acid liquid

A cross-linked acid, multi-component technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of restricting the popularization and application of emulsified acid, low filtration loss, low friction, safety hazards, etc., to meet the requirements of on-site construction Requirements, the effect of making seams beneficial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

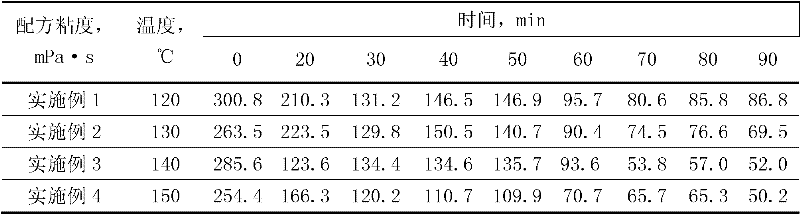

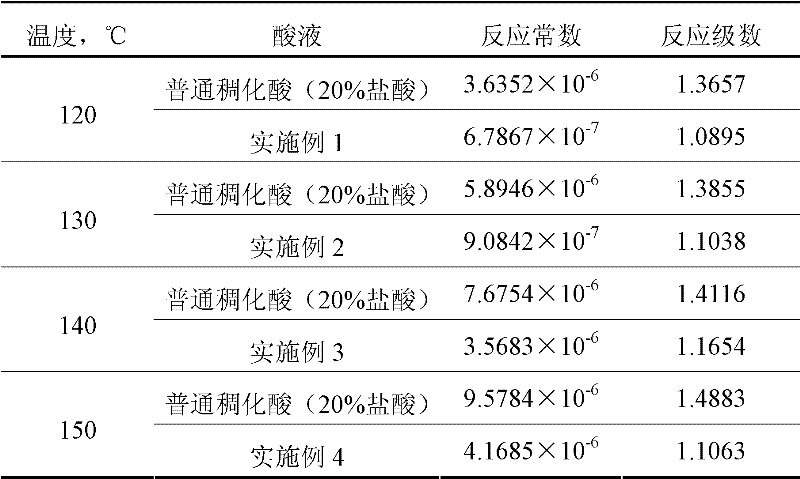

Embodiment 1

[0019] 3.6% formic acid, 4.8% acetic acid, 13.75% hydrochloric acid, and 71.25% water were made into an acid solution, and 4.0% high-temperature corrosion inhibitor was added. The high-temperature corrosion inhibitor was Mannich base and 2-alkyl-1-(N -Compound of polyoxyethylene-2-aminoethyl) imidazoline-1-benzyl ammonium fatty acid salt, dynamic corrosion rate at 160°C≤70g / (m 2 h), belongs to the first grade stipulated in the industry standard "SY / T 5405-1996 Corrosion Inhibitor Performance Test Method and Evaluation Index for Acidification"; iron ion stabilizer 1.0%, iron ion stabilizer is EDTA calcium sodium; long-acting clay Stabilizer 0.5%, long-acting clay stabilizer is epichlorohydrin and polyethylene polyamine copolymer; demulsification aid 0.5%, demulsification aid is polyoxyethylene alkyl alcohol ether nonionic surfactant; Under 2000r / min high-speed stirring, add thickener 0.6% to make base liquid, thickener is 2-acrylamide-2-methylpropane sulfonate, methacrylamide (...

Embodiment 2

[0022] 3.6% formic acid, 4.8% acetic acid, 13.75% hydrochloric acid, and 68.65% water were made into an acid solution, and 5.0% high-temperature corrosion inhibitor was added. The high-temperature corrosion inhibitor was Mannich base and 2-alkyl-1-(N -Compound of polyoxyethylene-2-aminoethyl) imidazoline-1-benzyl ammonium fatty acid salt, dynamic corrosion rate at 160°C≤70g / (m 2 h), belongs to the first grade stipulated in the industry standard "SY / T 5405-1996 Corrosion Inhibitor Performance Test Method and Evaluation Index for Acidification"; iron ion stabilizer 1.5%, iron ion stabilizer is EDTA calcium sodium; long-acting clay Stabilizer 1.0%, long-acting clay stabilizer is epichlorohydrin and polyethylene polyamine copolymer; demulsification aid and drainage agent 1.0%, demulsification aid and drainage agent is polyoxyethylene alkyl alcohol ether nonionic surfactant; Under 2000r / min high-speed stirring, add thickener 0.7% to make base liquid, thickener is 2-acrylamide-2-met...

Embodiment 3

[0025] 3.6% formic acid, 4.8% acetic acid, 13.75% hydrochloric acid, and 68.55% water were made into an acid solution, and 5.0% high-temperature corrosion inhibitor was added. The high-temperature corrosion inhibitor was Mannich base and 2-alkyl-1-(N -Compound of polyoxyethylene-2-aminoethyl) imidazoline-1-benzyl ammonium fatty acid salt, dynamic corrosion rate at 160°C≤70g / (m 2 h), belongs to the first grade stipulated in the industry standard "SY / T 5405-1996 Corrosion Inhibitor Performance Test Method and Evaluation Index for Acidification"; iron ion stabilizer 1.5%, iron ion stabilizer is EDTA calcium sodium; long-acting clay Stabilizer 1.0%, long-acting clay stabilizer is epichlorohydrin and polyethylene polyamine copolymer; demulsification aid and drainage agent 1.0%, demulsification aid and drainage agent is polyoxyethylene alkyl alcohol ether nonionic surfactant; Under 2000r / min high-speed stirring, add thickener 0.8% to make base liquid, thickener is 2-acrylamide-2-met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com