Method for extracting n-butyric acid, valeric acid and hexoic acid from lyechange as by-product of cyclohexanone production

A technology of by-products and waste lye, which is applied in the field of extracting n-butyric acid, n-caproic acid, and n-valeric acid, can solve problems such as pollution, waste of resources, and increase the production and operation cost of cyclohexanone, and achieve simple process and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

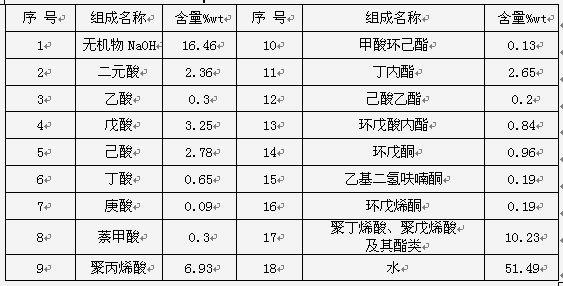

Image

Examples

Embodiment 1

[0021] 1. Take 10Kg of waste lye and 1.8Kg of concentrated sulfuric acid (98) and dilute the sulfuric acid into 75% sulfuric acid with the waste water produced by saponified oil distillation.

[0022] 2. Put 10Kg of waste lye into a plastic or glass container and cool it to a temperature below 50°C, then slowly pour the diluted sulfuric acid into the waste lye (stir while pouring). Use pH test paper to test the pH value, when the pH value is 3.0. Stop adding acid, stop stirring, and stand still for 10 minutes.

[0023] 3. Discharge the stratified sodium sulfate aqueous solution into the solvent, and the saponified oil into the distillation bottle.

[0024] 4. Add an appropriate amount of NaOH (content 25%-35%) to the sodium sulfate aqueous solution to adjust the pH value to 8.2, and then send it to distillation for dehydration. When the concentration of sodium sulfate reaches the requirements of centrifugal dehydration, the thick slurry is discharged into the concentration b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com