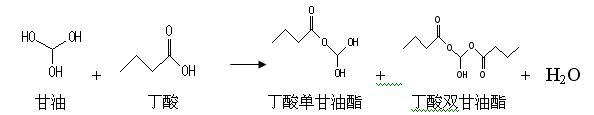

Synthesis method of functional feed additive butyric acid mono-and di-glyceride

A technology of butyric acid mono-diglycerol and feed additives, which is applied in the direction of animal feed, animal feed, carboxylate preparation, etc. It can solve the problems of ineffective effect and no reports of butyric acid mono-diglyceride, and achieves a simple and convenient preparation method Easy to control, convenient source of raw materials, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

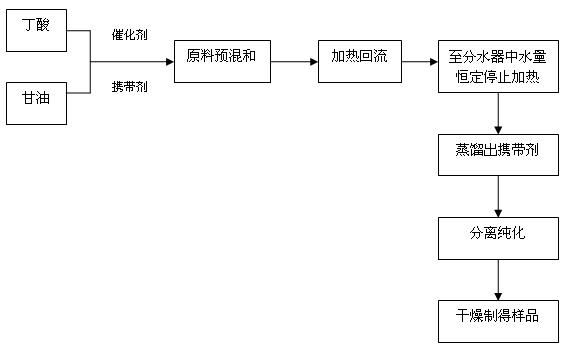

Method used

Image

Examples

Embodiment 1

[0024] Weigh 184g of glycerin, 141g of butyric acid, 7.4g of catalyst phosphoric acid, and 100ml of carbon tetrachloride with water agent, and add them to a 500ml three-neck flask equipped with a thermometer, a water separator and a reflux condenser, turn on the magnetic stirring, and heat up to reflux , when the temperature of the system rises to the highest temperature of 110°C, with the formation of water in the reaction, the temperature drops slowly, and when the amount of water in the water separator remains basically unchanged, the reaction is stopped, the reaction is refluxed for 2.5 hours, and the heating is stopped. Add zeolite and distill carbon tetrachloride to obtain crude product. The crude product was washed with weakly alkaline saturated saline for several times until the lower aqueous phase was alkaline, and the ester layer was poured out from the upper end of the separatory funnel, and dried in a drying oven for 3 h. After cooling, filter with a funnel plugged...

Embodiment 2

[0026] Weigh 184g of glycerin, 141g of butyric acid, 7.4g of catalyst phosphoric acid, and 80ml of carbon tetrachloride with water agent, and add them to a 500ml three-neck flask equipped with a thermometer, a water separator and a reflux condenser, turn on the magnetic stirring, and heat up to reflux , when the temperature of the system rises to the highest temperature of 108°C, with the formation of water in the reaction, the temperature drops slowly, and when the amount of water in the water separator remains basically unchanged, the reaction is stopped, the reaction is refluxed for 3 hours, and the heating is stopped. Add zeolite and distill carbon tetrachloride to obtain crude product. The crude product was washed with weakly alkaline saturated saline for several times until the lower aqueous phase was alkaline, and the ester layer was poured out from the upper end of the separatory funnel, and dried in a drying oven for 3 h. After cooling, filter with a funnel plugged wi...

Embodiment 3

[0028] Weigh 184 g of glycerin, 123 g of butyric acid, 9.2 g of catalyst phosphoric acid, and 100 mL of water-carrying agent carbon tetrachloride, and add them to a 500 mL three-necked flask equipped with a thermometer, a water separator and a reflux condenser, and start magnetic stirring. Heating to reflux, when the temperature of the system rises to the highest temperature of 103°C, the temperature drops slowly with the formation of water in the reaction, and when the amount of water in the water separator remains basically unchanged, the reaction is stopped, the reaction is refluxed for 3 hours, and the heating is stopped. Add zeolite and distill carbon tetrachloride to obtain crude product. The crude product was washed with weakly alkaline saturated saline for several times until the lower aqueous phase was alkaline, and the ester layer was poured out from the upper end of the separatory funnel, and dried in a drying oven for 3 h. After cooling, filter with a funnel plugge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com