Powdered solid cosmetic and manufacturing method therefor

A technology for solid cosmetics and powder, which is applied in the field of powder solid cosmetics and its preparation, and achieves the effect of excellent oily gloss prevention effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0145] Preparation method of powder solid cosmetic

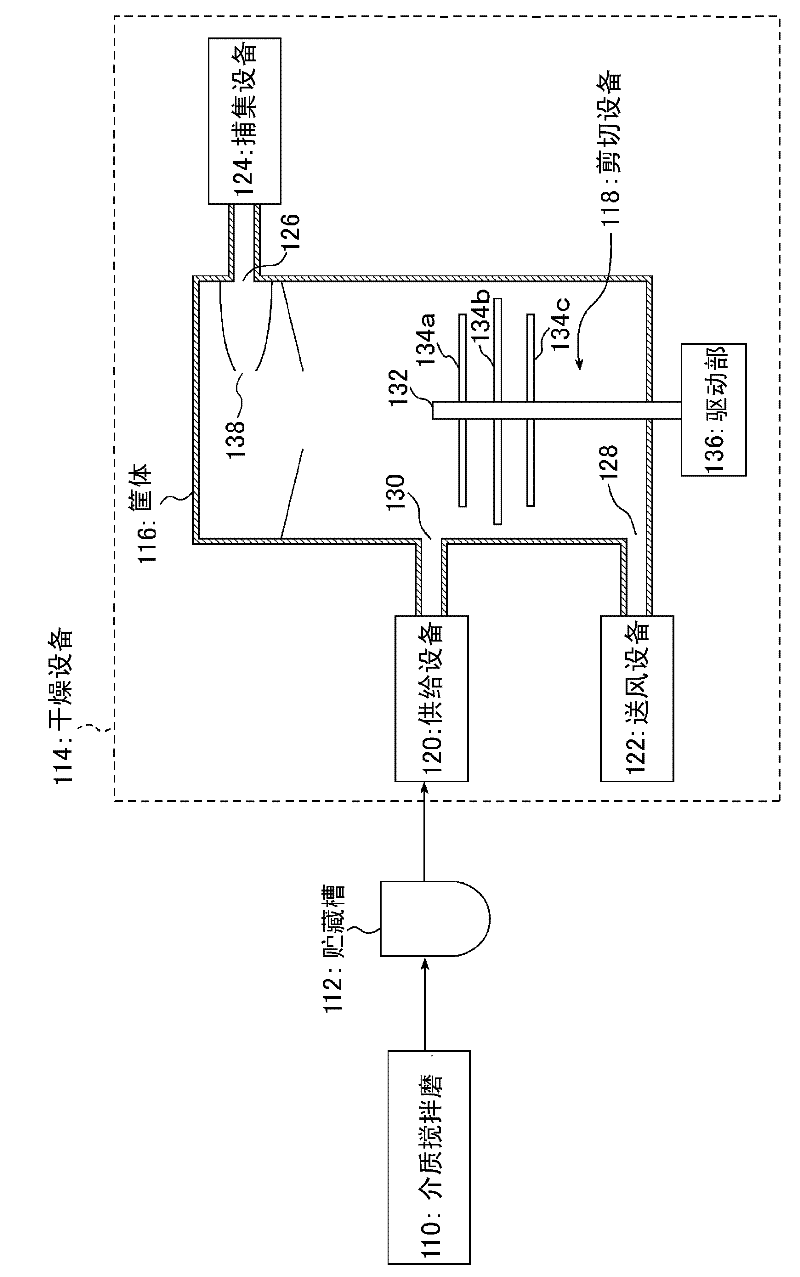

[0146] The powdery solid cosmetics of the present invention can be prepared by mixing various constituents including the amide mixture described above, the powder component and the oily component by a conventional method, for example, by a method of mixing under dry conditions (dry manufacturing method) , Dispersed in a wet system, slurried, and then dried to prepare any one of the methods (wet method).

[0147] dry method

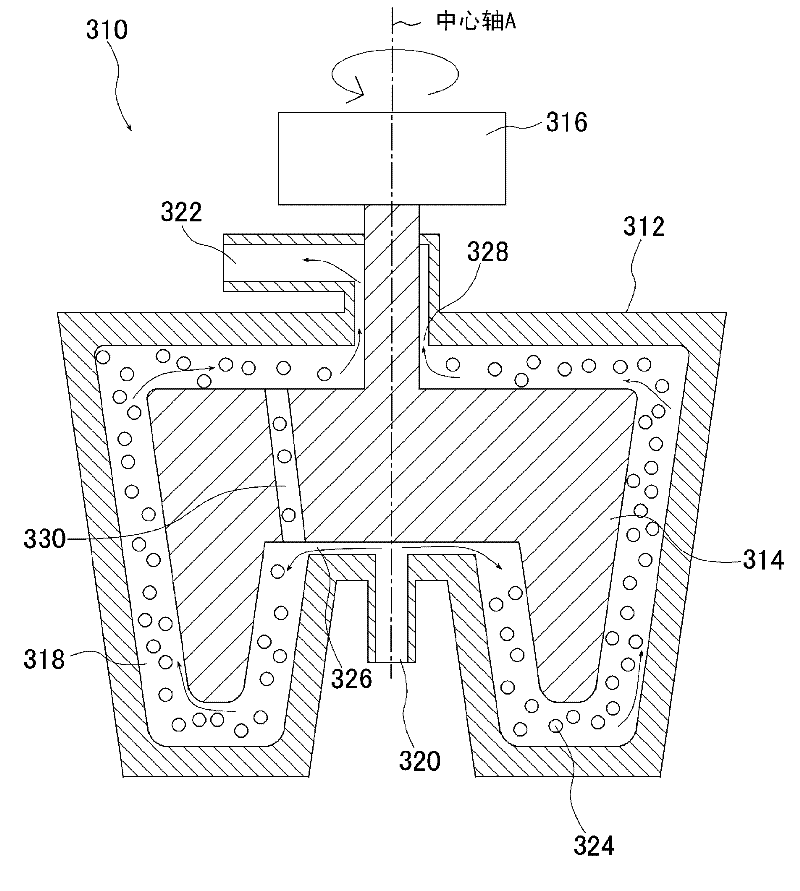

[0148] When preparing the powdery solid cosmetic of the present invention by a dry method, it is particularly preferable to mix the above-mentioned amide mixture with the powder component and the oily component using a mixer of a specific configuration with opposed rotors described below. By using this mixer with opposing rotor blades, it is possible to uniformly coat the surface of the oil-based component without agglomeration of the powder component, and the obtained powder solid cosmetics have a ...

Embodiment

[0202] Hereinafter, examples of the present invention will be given and described concretely, but the present invention is not limited thereto. In addition, the quantity in the following prescription shows by mass %.

[0203]

[0204] (A) Evaluation of Makeup Persistence (makeup faded and oily)

[0205] The formulations shown in the table below prepared foundation foundations through the above-mentioned slurry preparation steps and powder solid cosmetic preparation steps, and the following methods were used to conduct subject tests for the makeup durability. The obtained foundation was applied to the skin by 10 test subjects specialized in cosmetics. Then, 3 hours later, 3 professional evaluators performed a 10-level evaluation based on the following evaluation criteria for each evaluation item of "Evaluation of makeup change" and "Evaluation of oily shine" (makeup durability is very poor: 0 points to makeup durability Very good performance: 10 points), and further judged ...

preparation example 7-1

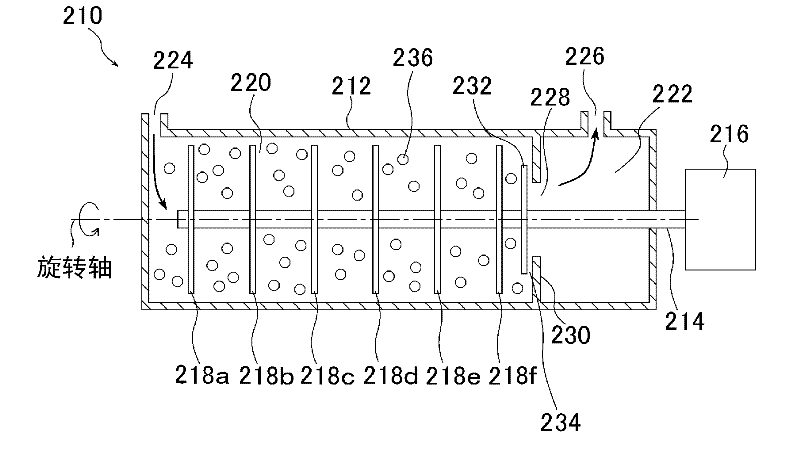

[0274] Preparation Example 7-1: After mixing the various ingredients in the prescription with a Henschel mixer (manufactured by Mitsui Miike Chemical Industry Co., Ltd.) for a certain period of time, use figure 1 Rotary wing opposing type mixing device (cyclone grinder: Flowtec Corporation, the first rotor and the second rotor are used to rotate in opposite directions to each other) to mix twice, and dry press molding in a resin medium vessel .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com