Composite soil conditioner for treating Cd pollution, and preparation and use methods thereof

A soil conditioner and formula technology, which is applied in the environmental field to achieve the effects of simple application and promotion, high-efficiency physical and chemical properties, and improvement of soil physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a composite soil conditioner for treating heavy metal Cd pollution, comprising the following steps: fully stirring clay minerals, peat, biochar, slaked lime and iron oxide until uniformly mixed; adding microbial bacterial agents by 5-10% , made of inorganic-organic composite conditioner.

[0035] The clay minerals are mainly kaolinite, montmorillonite and illite, which are crushed and passed through a 40-mesh sieve for later use. The kaolin mentioned above should meet the requirements of GB / T14563-2008, and the montmorillonite and illite should meet the requirements of GB / T14563-2008.

[0036] The organic matter content in the peat is mostly 40-70%, and the pH value is 6.0-7.0, which is pulverized by a pulverizer and passed through a 40-mesh sieve for later use.

[0037] The slaked lime is a strong alkaline substance produced by limestone through processes such as calcination, digestion, separation and deslagging, and centrifugal dehydration. The...

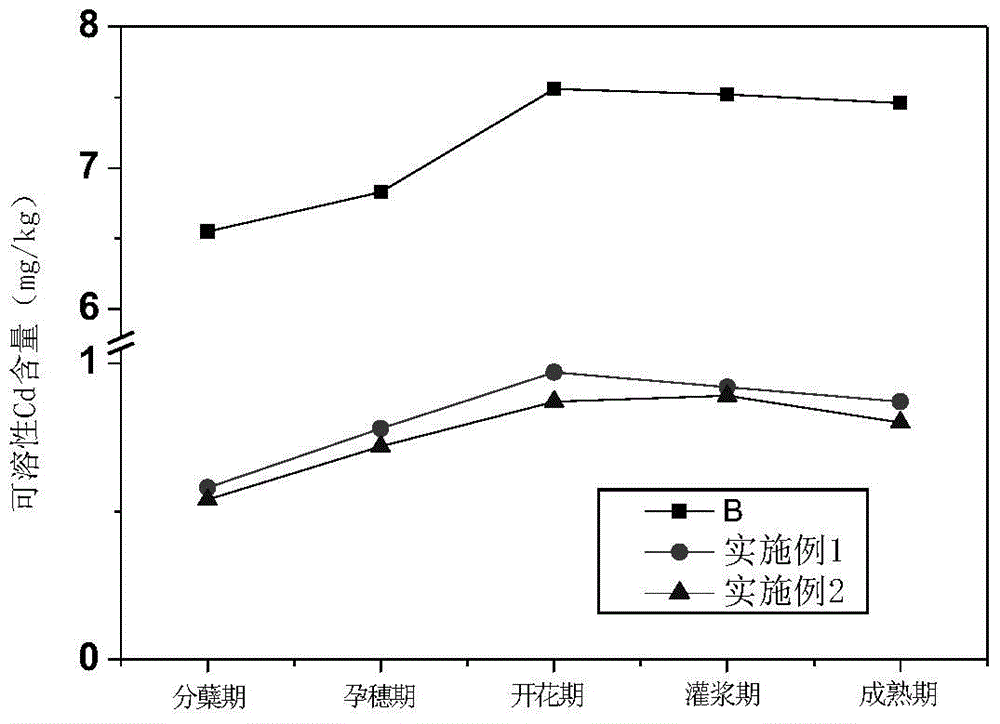

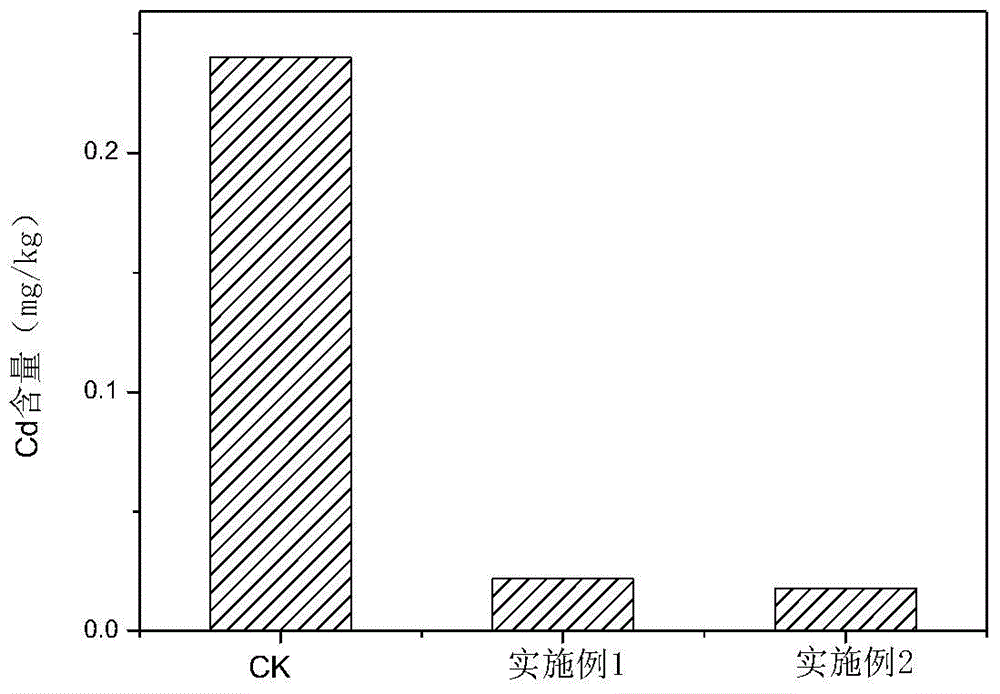

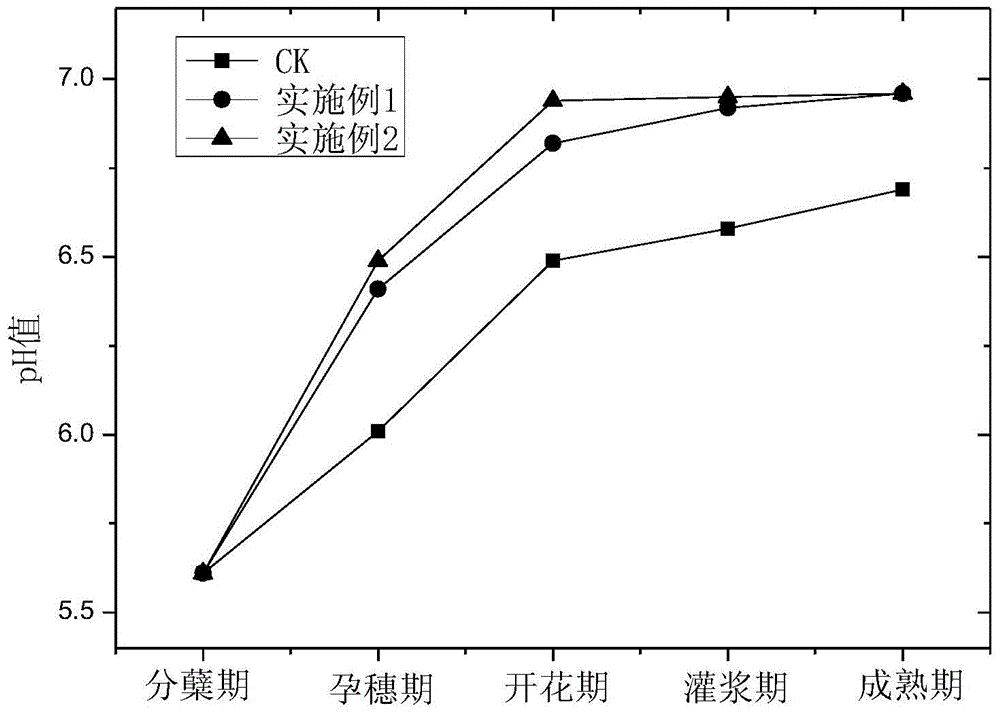

Embodiment 1

[0045] Embodiment 1: The preparation of the compound soil conditioner that is used to control heavy metal Cd pollution

[0046] Clay minerals, peat, biochar, humic acid and slaked lime are pulverized by a pulverizer, sieved with 40 meshes, fully stirred until mixed evenly, and microbial bacterial agents are added in a proportion of 5%. Among them, the addition ratio of clay minerals, peat, biochar, slaked lime and iron oxide is 25:15:15:30:10.

[0047] The clay minerals are mainly kaolinite, which is crushed and passed through a 40-mesh sieve for later use. The kaolinite should meet the requirements of GB / T14563-2008.

[0048] The peat has an organic matter content of 60% and a pH value of 7.0, which is pulverized by a pulverizer and passed through a 40-mesh sieve for later use.

[0049] The slaked lime is a strong alkaline substance produced by limestone through processes such as calcination, digestion, separation and deslagging, and centrifugal dehydration. The main compon...

Embodiment 2

[0051] Embodiment 2: be used for the preparation of the compound soil conditioner of controlling heavy metal Cd pollution

[0052] Clay minerals, peat, biochar, humic acid and slaked lime are pulverized by a pulverizer, sieved with 40 meshes, fully stirred until mixed evenly, and microbial bacterial agents are added in a proportion of 5%. Among them, the addition ratios of clay minerals, peat, biochar, slaked lime and iron oxides are 20:15:15:35:5, respectively.

[0053] Clay minerals are selected from montmorillonite, crushed and sieved with 40 meshes for later use. The montmorillonite meets the requirements of GB / T14563-2008.

[0054] The organic matter content in the peat is 50%, the pH value is 6.5, it is pulverized by a pulverizer and passed through a 40-mesh sieve for later use.

[0055] The slaked lime is a strong alkaline substance produced by limestone through processes such as calcination, digestion, separation and deslagging, and centrifugal dehydration. The main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com