Contaminated soil passivator and preparation method and application thereof

A technology of polluted soil and passivator, which is applied in the restoration of polluted soil, chemical instruments and methods, application and other directions, can solve the problem of reducing the content of available heavy metals in soil crops, poor adsorption and exchange performance of heavy metals, and complex preparation process of adsorbents and other problems, to achieve the effect of improving long-term stability, reducing dissolution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

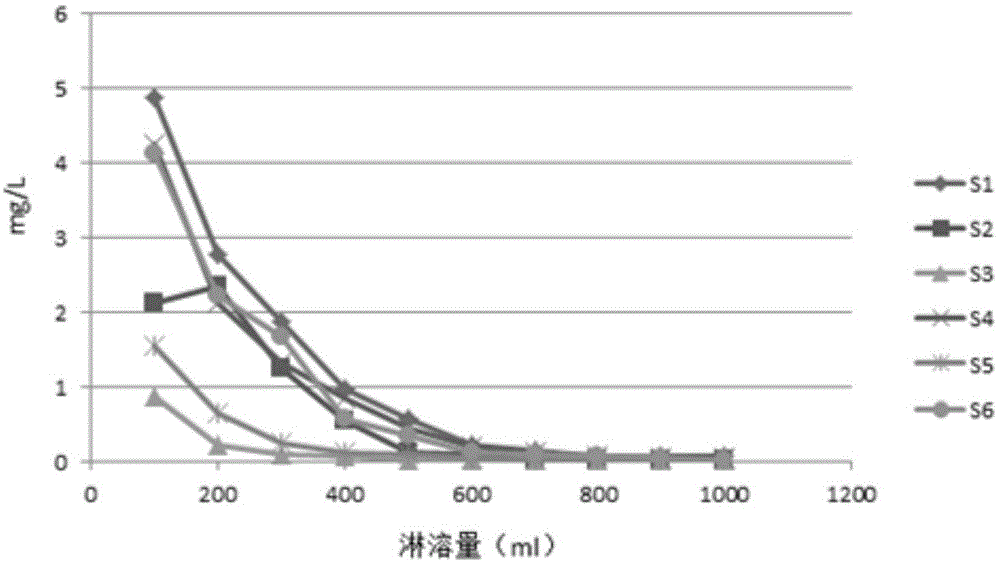

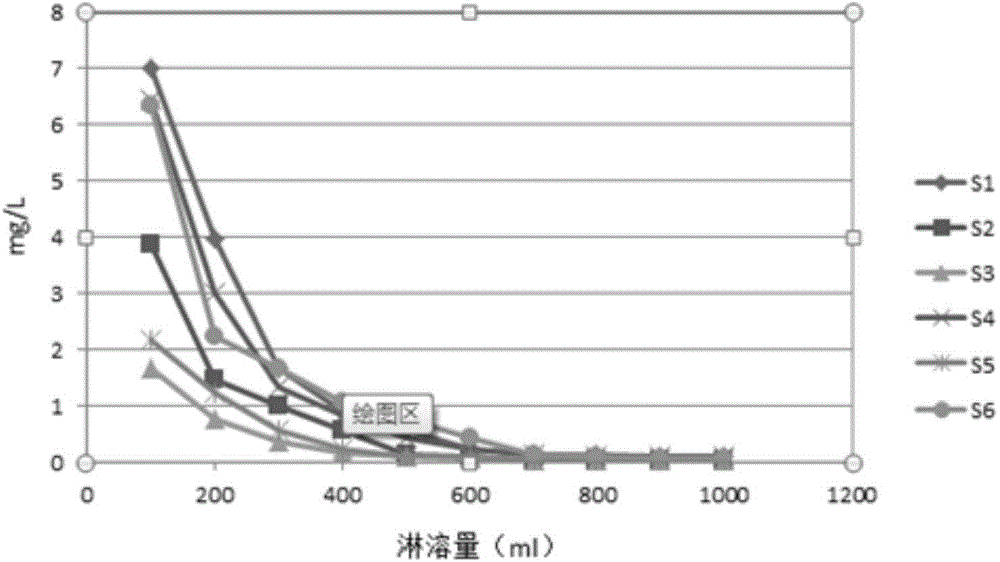

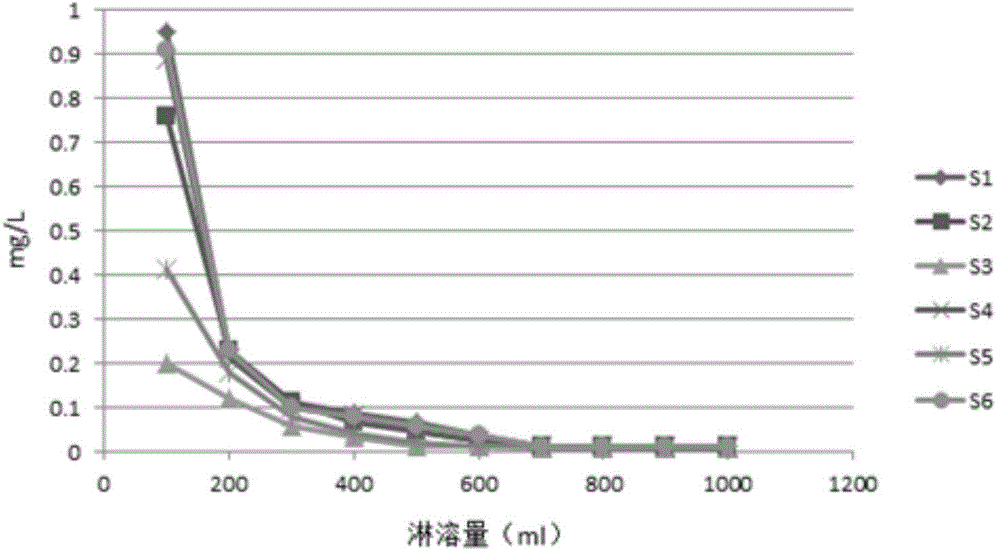

[0032] Cd, Cu, Hg complex heavy metal pollution passivation:

[0033] Take 70kg of the above-mentioned polluted soil, divide it into 7 parts, numbered S1-S6, and S1 is a blank polluted soil, add different passivating agents to S2-S6 respectively, the total addition amount is not more than 2.5kg, fully stir, so that the passivating agent and Mix the contaminated soil evenly, pour it into the prepared water agent, and ensure that the soil moisture content is 30%, keep the moisture in the stack for 7 days, and measure the leaching amount of heavy metals in the soil. The specific test results are shown in the table below:

[0034]

[0035] Class 3A small-pore molecular sieves have very poor adsorption and exchange performance for heavy metals due to the limitation of pore size. Due to the heterogeneous crystal phase and irregular pores of natural zeolite, its adsorption and exchange performance for heavy metals is not very good.

[0036] Long-term stability test of passivated...

Embodiment 2

[0039] A polluted soil passivator, which is formed by mixing the following raw materials in weight percentage: 30% of natural clay mineral material (bentonite), 60% of industrial harmless waste (blast furnace slag), and 10% of cation exchanger (X-type molecular sieve). Mix natural clay mineral materials and industrial harmless wastes, then fully mix them with cation exchangers, and crush them to less than 100 meshes to obtain polluted soil passivation agents.

[0040] The soil used for the test was taken from a polluted site in Shanghai, and the total amount of heavy metals measured was Cd122mg / kg, Cu488mg / kg, and Hg150mg / kg.

[0041] Add the passivator to the polluted soil in an amount of 20wt%, and the addition ratio of the passivator is determined according to the degree of pollution. In order to ensure that the polluted soil and the passivator are mixed evenly, the moisture content of the polluted soil must be controlled below 15%. Make passivator and polluted soil mix eve...

Embodiment 3

[0044] A polluted soil passivator, which is formed by mixing the following raw materials in weight percentage: 60% of natural clay mineral material (attapulgite), 30% of industrial harmless waste (fly ash), cation exchanger (pore diameter greater than 4A) molecular sieve) 10%. Mix natural clay mineral materials and industrial harmless wastes, then fully mix them with cation exchangers, and crush them to less than 100 meshes to obtain polluted soil passivation agents.

[0045] The application of polluted soil passivator, in polluted soil, apply passivator by the addition amount of 15wt%, and wherein the addition ratio of passivator is determined according to pollution degree, in order to guarantee that polluted soil and passivator are mixed evenly, polluted soil The moisture content needs to be controlled below 15%; the passivating agent and the polluted soil are evenly mixed, poured into the prepared mixed acid solution of nitric acid and sulfuric acid with a pH value of 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com