Method for simultaneously stabilizing heavy metals and deeply dewatering municipal sludge for municipal sludge

A technology for dewatering municipal sludge and sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve problems such as long treatment cycle, reduced leaching rate, and limited resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: Stability determination and speciation determination of heavy metals in dewatered sludge

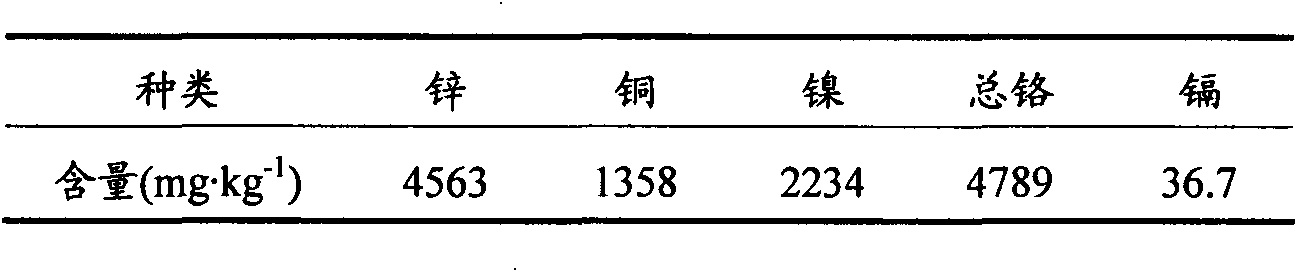

[0069] Take the sludge from a sewage treatment plant in Shanghai, the water content is 81%, and the heavy metal content is as follows:

[0070]

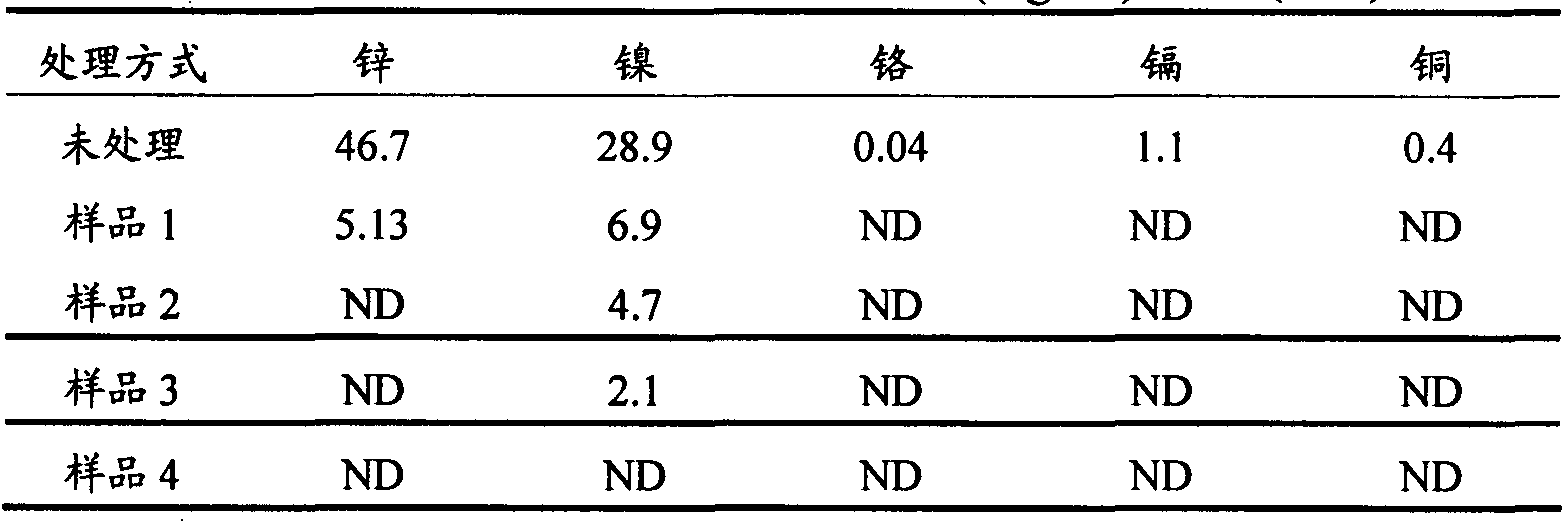

[0071] Four parts of the same weight of the above sludge were taken as sample 1, sample 2, sample 3 and sample 4 respectively.

[0072] According to the above-mentioned steps (1) and (2) in the method of the present invention, in percentage by weight, add successively in sample 1 the ferrous sulfate heptahydrate that is 10% of sludge dry weight and the ferrous sulfate that is 5% of sludge dry weight lime (calcium hydroxide).

[0073] According to the above-mentioned steps (1)-(3) in the method of the present invention, in percentage by weight, add successively in sample 2 the ferrous sulfate heptahydrate that is 10% of sludge dry weight, be the ferrous sulfate heptahydrate of 5% of sludge dry weight Calcium hydroxide and ...

Embodiment 2-3

[0094] Embodiment 2-3: Stability determination and speciation determination of heavy metals in dewatered sludge

[0095] Except that the order of adding sample 4 is changed to add successively the ferrous sulfate heptahydrate which is 10% of the dry weight of the sludge, the calcium hydroxide which is 5% of the dry weight of the sludge, and the fluorophosphorus ash which is 2.5% of the dry weight of the sludge. stone and the clay mineral (corresponding embodiment 2) that is 2.5% of sludge dry weight, and change to add successively the ferrous sulfate heptahydrate that is sludge dry weight 10%, the calcium hydroxide that is sludge dry weight 5% In addition to the homogeneous mixture (corresponding to Example 3) obtained by mixing the clay minerals of 2.5% of the sludge dry weight with the fluorapatite of the sludge dry weight of 2.5%, carried out respectively in the same manner as in Example 1 Examples 2 and 3, and carried out heavy metal leaching test and speciation distribut...

Embodiment 4

[0097] Example 4: Stability determination and speciation determination of heavy metals in dewatered sludge

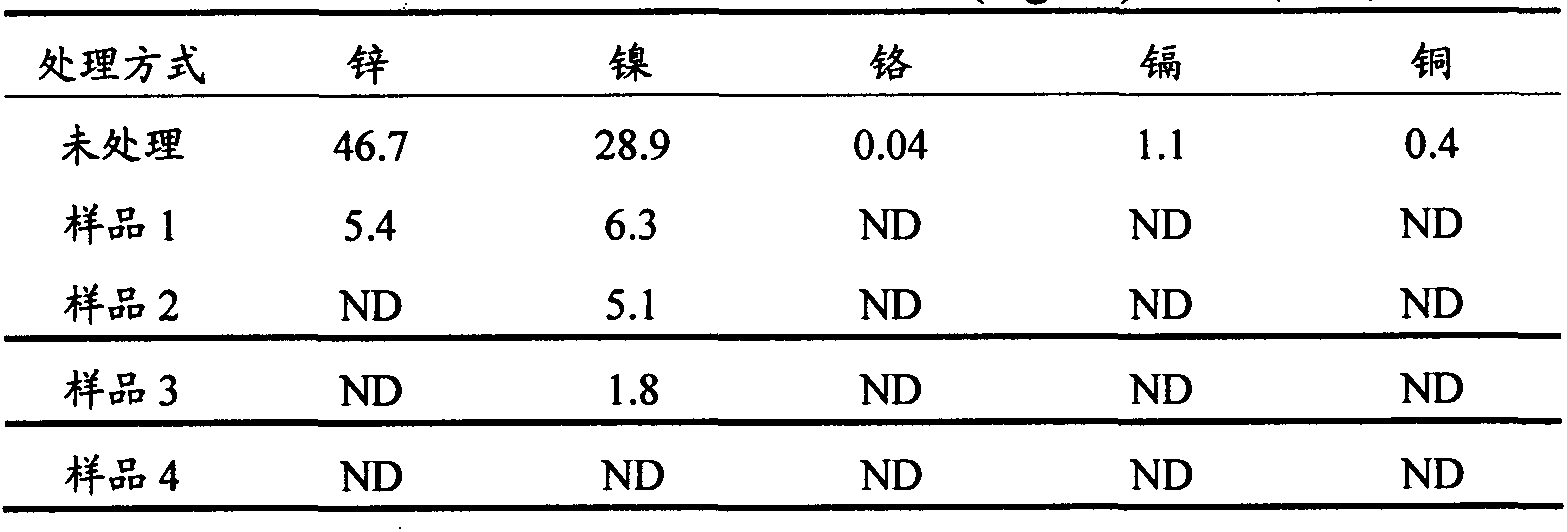

[0098] In addition to adding various components accounting for the following percentages of sludge dry weight in the following samples, and the kaolinite added therein has a Blaine specific surface area of 3000cm 2 / g, particle size is 400 orders, and the particle size of fluoroapatite is outside 400 orders, has carried out heavy metal leaching test and shape distribution determination in the same manner as embodiment 1:

[0099] Sample 1: 15% ferrous sulfate heptahydrate + 7.5% lime;

[0100] Sample 2: 15% ferrous sulfate heptahydrate + 7.5% lime + 10% kaolinite;

[0101] Sample 3: 15% ferrous sulfate heptahydrate + 7.5% lime + 10% fluorapatite;

[0102] Sample 4: 15% ferrous sulfate heptahydrate + 7.5% lime + 5% kaolinite + 5% fluorapatite.

[0103] The stability results are shown in Table 2 below.

[0104] Table 2. Heavy metal leaching concentrations before a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com