Sea-island fiber water-soluble polyester and preparation method thereof

A technology of sea-island fiber and water-soluble polyester, which is applied in the direction of conjugated synthetic polymer rayon, etc., can solve the problem that the solution is not environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

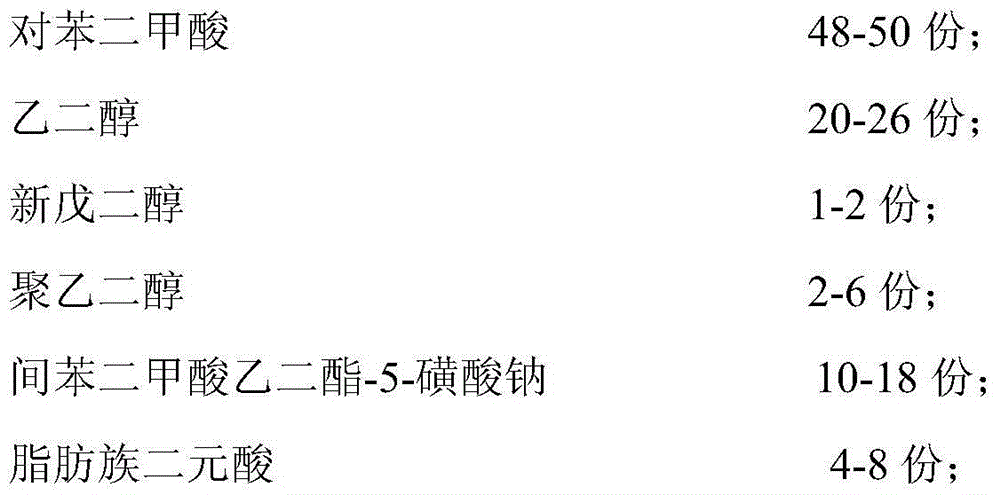

[0025] Sea-island fiber water-soluble polyester is prepared by the following method in the present embodiment:

[0026] 1. Esterification stage

[0027] Mix 11kg of refined terephthalic acid, 4.93kg of ethylene glycol and 0.25kg of neopentyl glycol, add 5.6g of catalyst antimony trioxide and 2.6g of stabilizer trimethyl phosphate at the same time, stir and mix evenly, at 240- React at 250°C and 0.2-0.3MPa for 3-4 hours, and the end of the reaction is determined by the amount of distilled water reaching the theoretically calculated value; after the reaction, add 2.92kg of SIPE, 1.4kg of adipic acid, and 0.8 kg of polyethylene glycol to the reaction solution kg, carry out mixing modification, and react at 230-250°C under normal pressure for 1-1.5 hours to obtain a copolymerized modified ester compound;

[0028] 2. Polymerization stage

[0029] React the copolymerized modified esterified product obtained in the esterification stage at a pressure of 1KPa and a temperature of 250...

Embodiment 2

[0032] Sea-island fiber water-soluble polyester is prepared by the following method in the present embodiment:

[0033] 1. Esterification stage

[0034] 15kg of refined terephthalic acid, 6.73kg of ethylene glycol and 0.32kg of neopentyl glycol were mixed, and 7.6g of catalyst antimony trioxide and 3.6g of stabilizer trimethyl phosphate were added at the same time, stirred and mixed evenly, at 240 React at -250°C and 0.2-0.3MPa for 3-4 hours, and the end of the reaction is determined by the amount of distilled water reaching the theoretical calculation value; after the reaction, add 3.98kg of SIPE, 1.9kg of adipic acid, and polyethylene glycol to the reaction solution 1.1kg, mixed and modified, and reacted at 230-250°C under normal pressure for 1-1.5 hours to obtain a copolymerized modified ester compound;

[0035] 2. Polymerization stage

[0036] React the copolymerized modified esterified product obtained in the esterification stage at a pressure of 1KPa and a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com