Novel compound material propeller

A composite material, propeller technology, applied in propeller, transportation and packaging, aircraft parts, etc., can solve the problems of low production efficiency, complex propeller molding process, low production efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

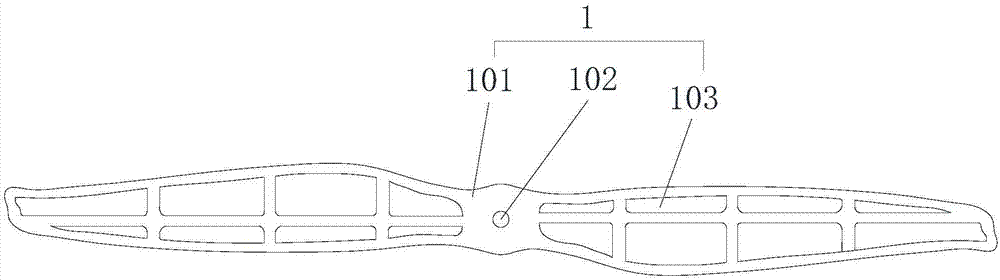

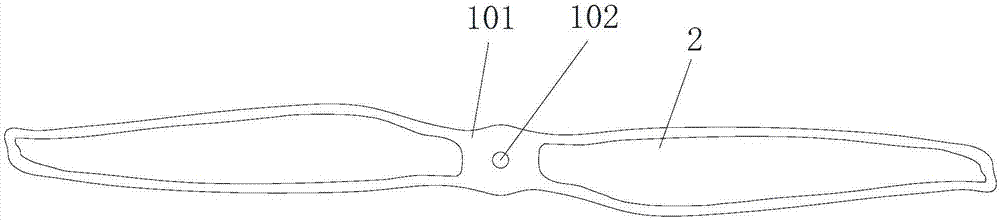

[0020] refer to figure 1 and figure 2 , a new type of composite material propeller proposed by the present invention includes a skeleton 1 and a skin layer 2, the skeleton 1 includes a skeleton body 101, a mounting hole 102 and a hollow 103, and the center of the skeleton body 101 is provided with a mounting hole 102, The skeleton body 101 is provided with an irregular hollow 103 , and the skin layer 2 is adhered to the hollow 103 .

[0021] The raw materials of the skeleton body 101 include by weight: 55 parts of polystyrene, 25 parts of polymethyl methacrylate, 10 parts of polystyrene, 6 parts of polyvinyl chloride, 6 parts of polyolefin, 5 parts of unsaturated polyester resin 3.5 parts of styrene-butadiene-styrene triblock copolymer, 2.5 parts of ethylene-vinyl acetate copolymer, 4.5 parts of polytetrafluoroethylene resin, 5 parts of polyhydroxybutyrate, 4.5 parts of chopped carbon fiber, 6.5 parts of urea-formaldehyde resin, 6 parts of trimethyl phosphate, 3.5 parts of ...

Embodiment 2

[0026] refer to figure 1 and figure 2 , a new type of composite material propeller proposed by the present invention includes a skeleton 1 and a skin layer 2, the skeleton 1 includes a skeleton body 101, a mounting hole 102 and a hollow 103, and the center of the skeleton body 101 is provided with a mounting hole 102, The skeleton body 101 is provided with an irregular hollow 103 , and the skin layer 2 is adhered to the hollow 103 .

[0027] The raw materials of the skeleton body 101 include by weight: 50 parts of polystyrene, 30 parts of polymethyl methacrylate, 5 parts of polystyrene, 8 parts of polyvinyl chloride, 3 parts of polyolefin, 6 parts of unsaturated polyester resin 2 parts, styrene-butadiene-styrene triblock copolymer 2 parts, ethylene-vinyl acetate copolymer 4 parts, polytetrafluoroethylene resin 3 parts, polyhydroxybutyrate 8 parts, chopped carbon fiber 3 parts, 9 parts of urea-formaldehyde resin, 3 parts of trimethyl phosphate, 5 parts of zinc stearate, 1 pa...

Embodiment 3

[0032] refer to figure 1 and figure 2 , a new type of composite material propeller proposed by the present invention includes a skeleton 1 and a skin layer 2, the skeleton 1 includes a skeleton body 101, a mounting hole 102 and a hollow 103, and the center of the skeleton body 101 is provided with a mounting hole 102, The skeleton body 101 is provided with an irregular hollow 103 , and the skin layer 2 is adhered to the hollow 103 .

[0033] The raw materials of the skeleton body 101 include by weight: 60 parts of polystyrene, 20 parts of polymethyl methacrylate, 15 parts of polystyrene, 4 parts of polyvinyl chloride, 9 parts of polyolefin, 4 parts of unsaturated polyester resin 5 parts of styrene-butadiene-styrene triblock copolymer, 1 part of ethylene-vinyl acetate copolymer, 6 parts of polytetrafluoroethylene resin, 2 parts of polyhydroxybutyrate, 6 parts of chopped carbon fiber, 4 parts of urea-formaldehyde resin, 9 parts of trimethyl phosphate, 2 parts of zinc stearate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com