Preparation method of nanometer rare earth silicate powder

A technology of silicate powder and nano-rare earth, applied in chemical instruments and methods, rare earth metal compounds, silicon compounds, etc., to achieve the effect of no oxidation phenomenon, narrow particle size distribution, and excellent heat insulation performance

Inactive Publication Date: 2012-04-04

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But so far, there has been no report on the method of synthesizing nano-scale rare earth silicate powder at low temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

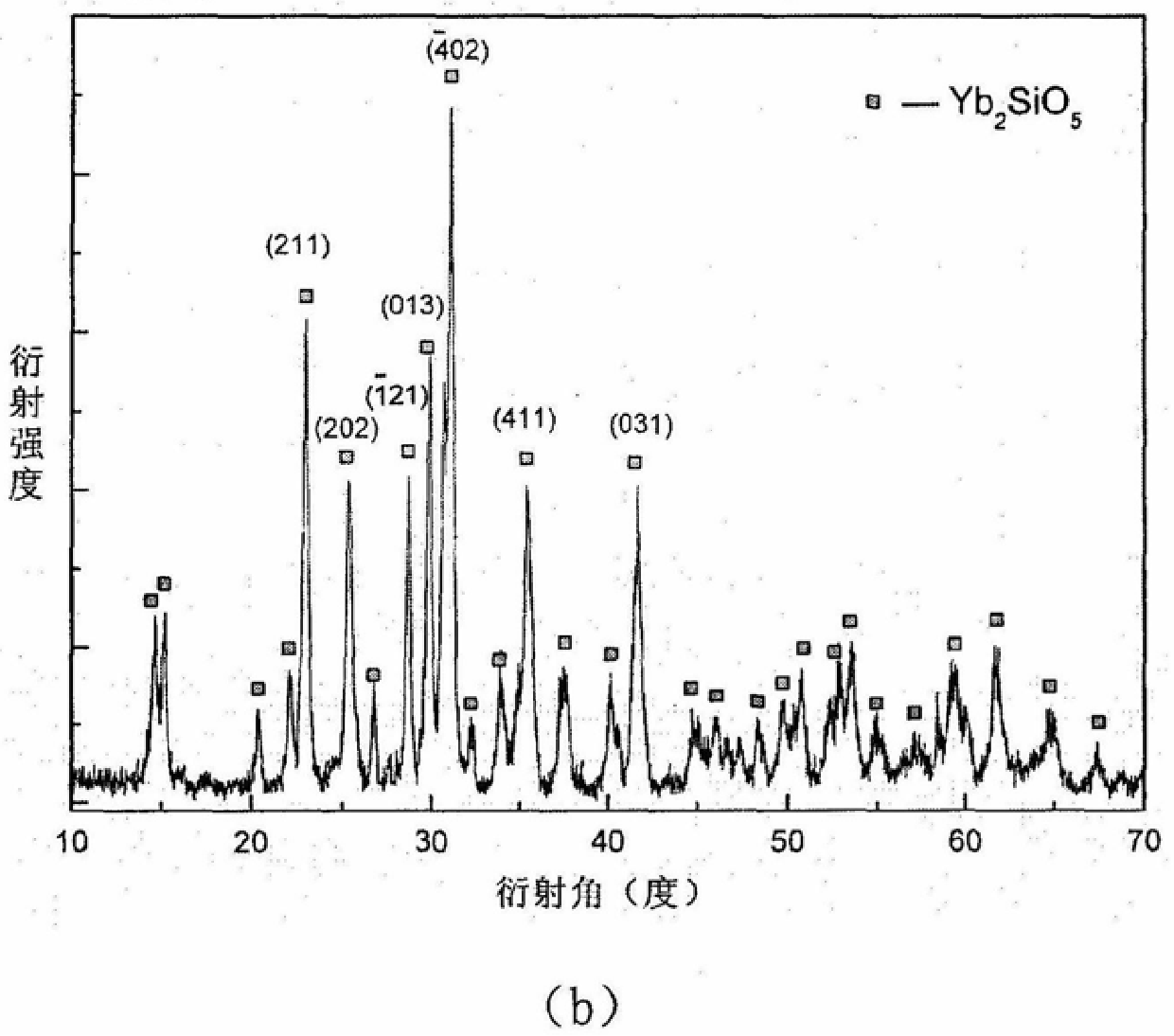

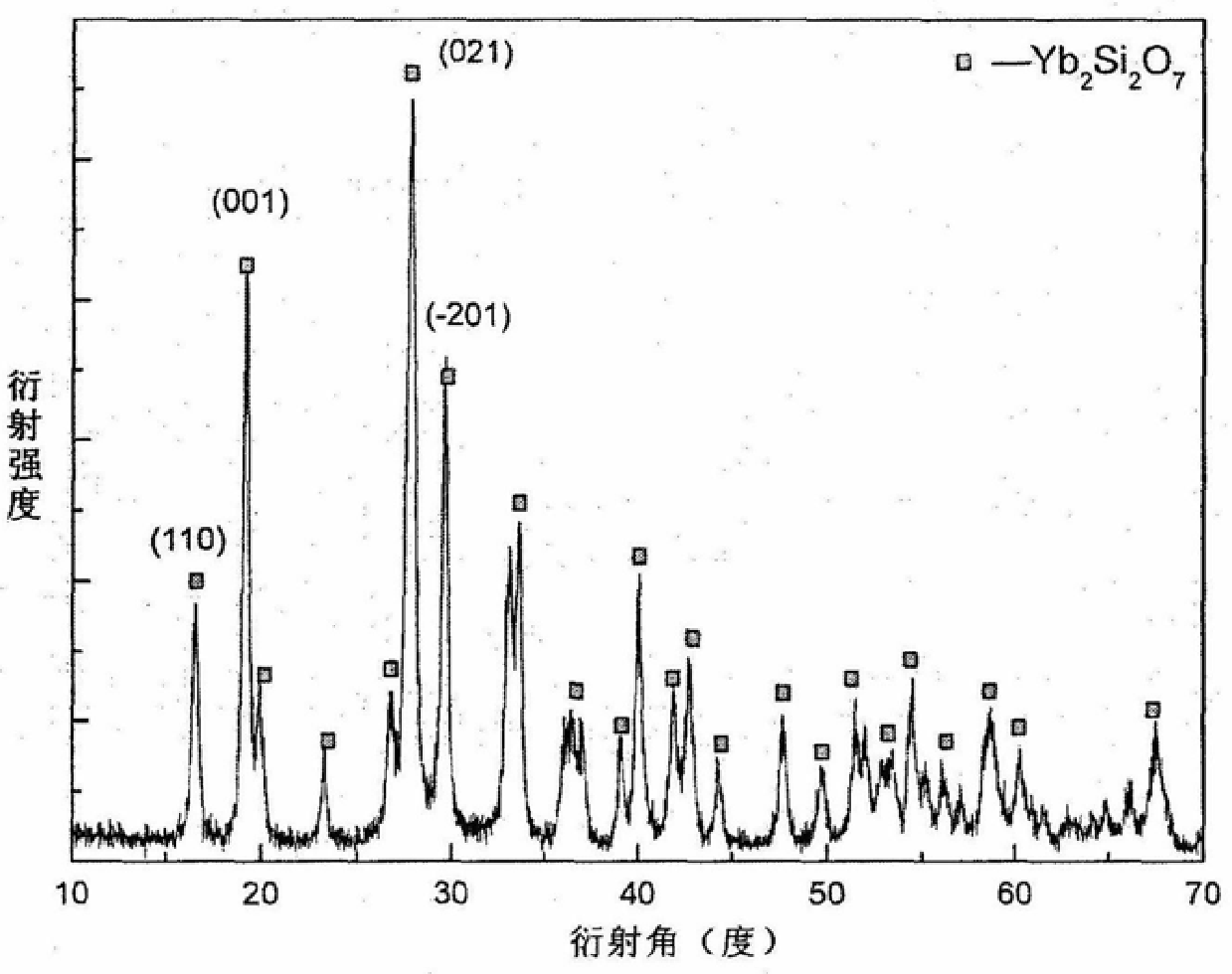

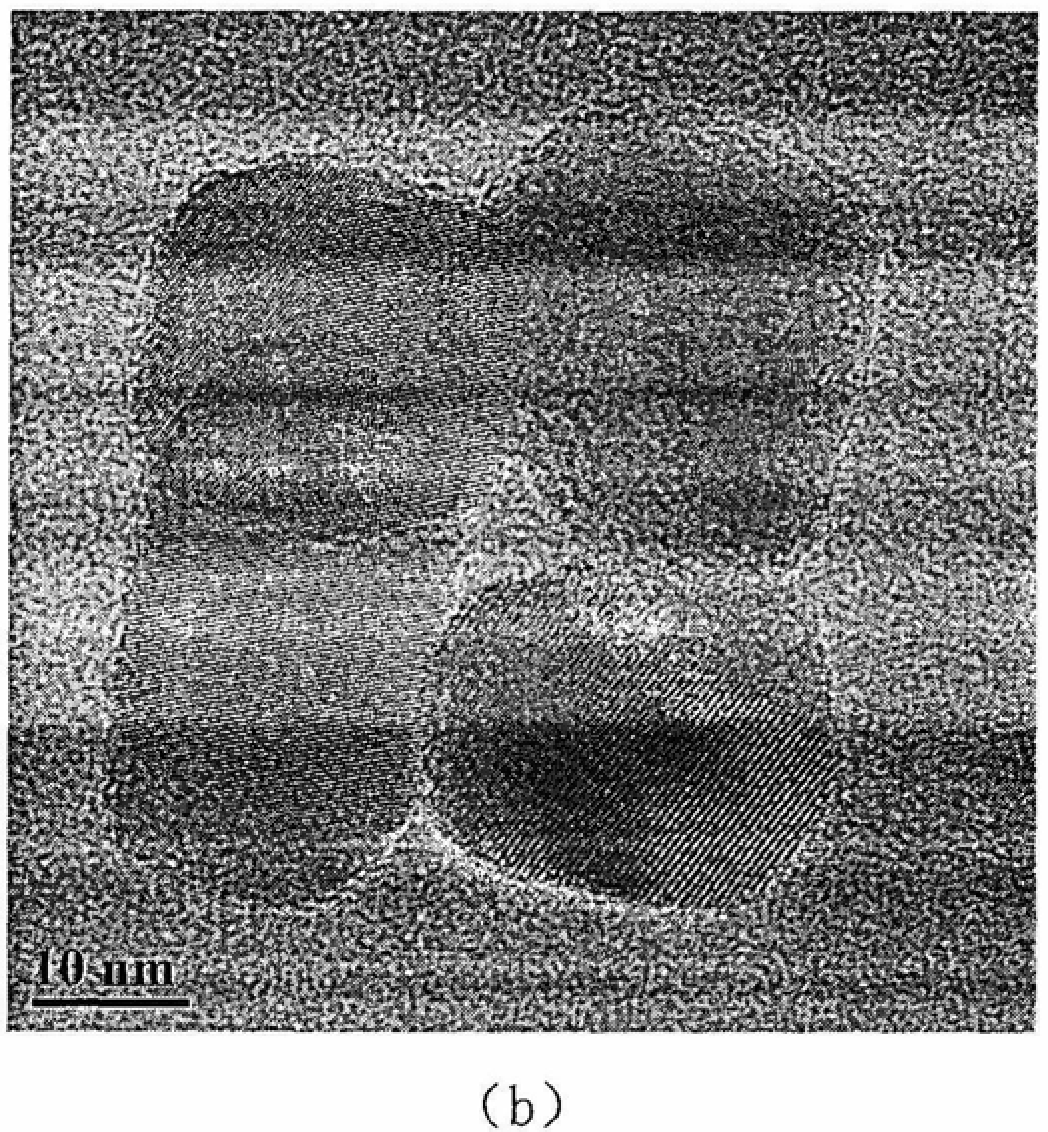

The invention relates to a preparation method of nano-rare earth silicate powder, which is characterized in that a certain stoichiometric ratio of rare earth oxides or rare earth soluble salts and silicon sources are formulated into solutions respectively, and the two solutions are mixed, and continuously After reacting for 6-24 hours, filtering and drying, monodisperse particles with a particle diameter of 20-30 nm can be obtained. Compared with the commonly used solid-phase reaction method and co-precipitation-calcination method, the synthesis method provided by the present invention has a synthesis temperature lowered by 1000-1300°C, which is more environmentally friendly and energy-saving; the obtained product has good oxidation resistance and compatibility with the substrate Physical and chemical compatibility of materials. The powder obtained by the method of the invention can be used to prepare the anti-oxidation coating on the surface of C / C composite materials and non-oxide silicon-based ceramic materials.

Description

Preparation method of nano rare earth silicate powder technical field The invention relates to a preparation method of nanometer rare earth silicate powder, belonging to the field of thermal barrier materials. Background technique Silicon-based non-oxide ceramics SiC, Si 3 N 4 The high temperature mechanical properties have reached σ=720MPa (1400°C), K IC =15-20MPa (900°C), and has shown good stability in the laboratory dry environment, so it is considered to be the most promising structural material to replace nickel-based superalloys for engine hot-end parts. However, the engine operating environment often contains water vapor. Water vapor reacts with silicon-based non-oxide ceramics at high temperature to form volatile silicon-containing products, which will cause serious surface degradation and quality loss of silicon-based ceramics. Therefore, how to improve the surface stability of silicon-based non-oxide ceramics in the working environment of the engine becomes...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B33/20C01F17/00C04B35/50

Inventor 高彦峰陈宏飞罗宏杰

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com