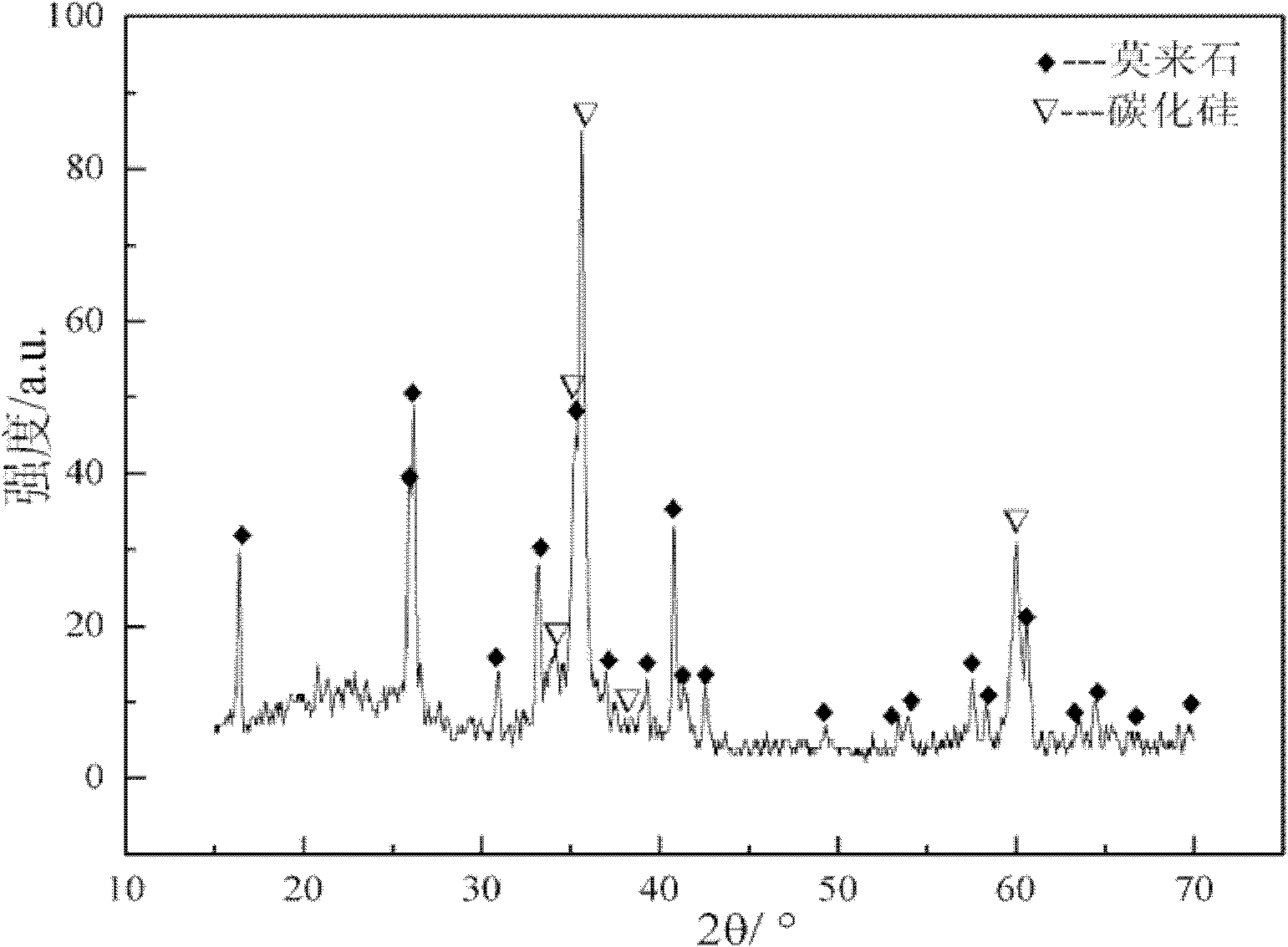

Preparation method of SiC coated mullite complex coating of C/C composite material

A composite coating and composite material technology, which is applied in the field of preparation of C/C composite composite coatings, can solve the problems of extreme preparation conditions, expensive equipment and harsh preparation processes, etc., and achieves high oxidation resistance, uniform thickness, Good physicochemical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

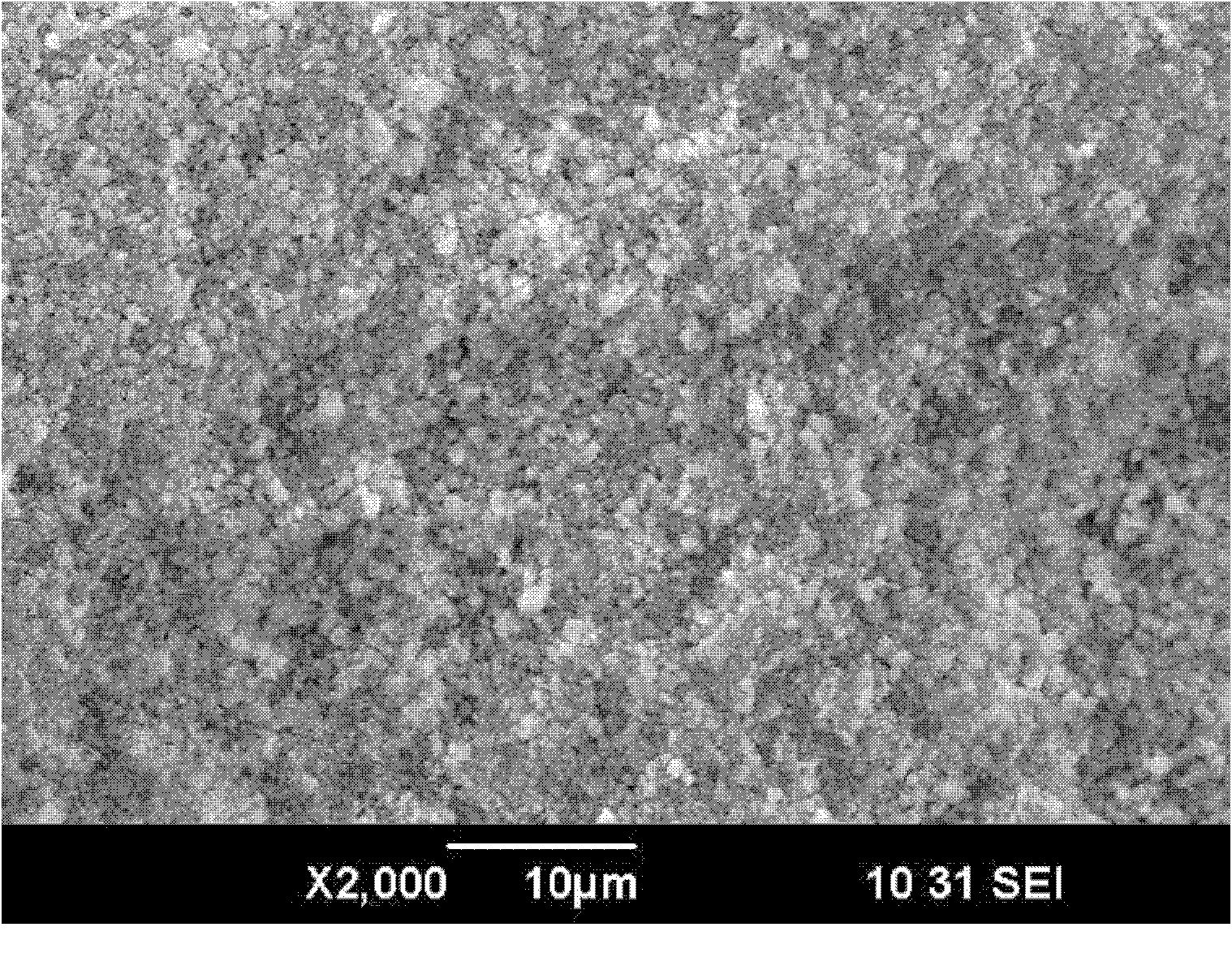

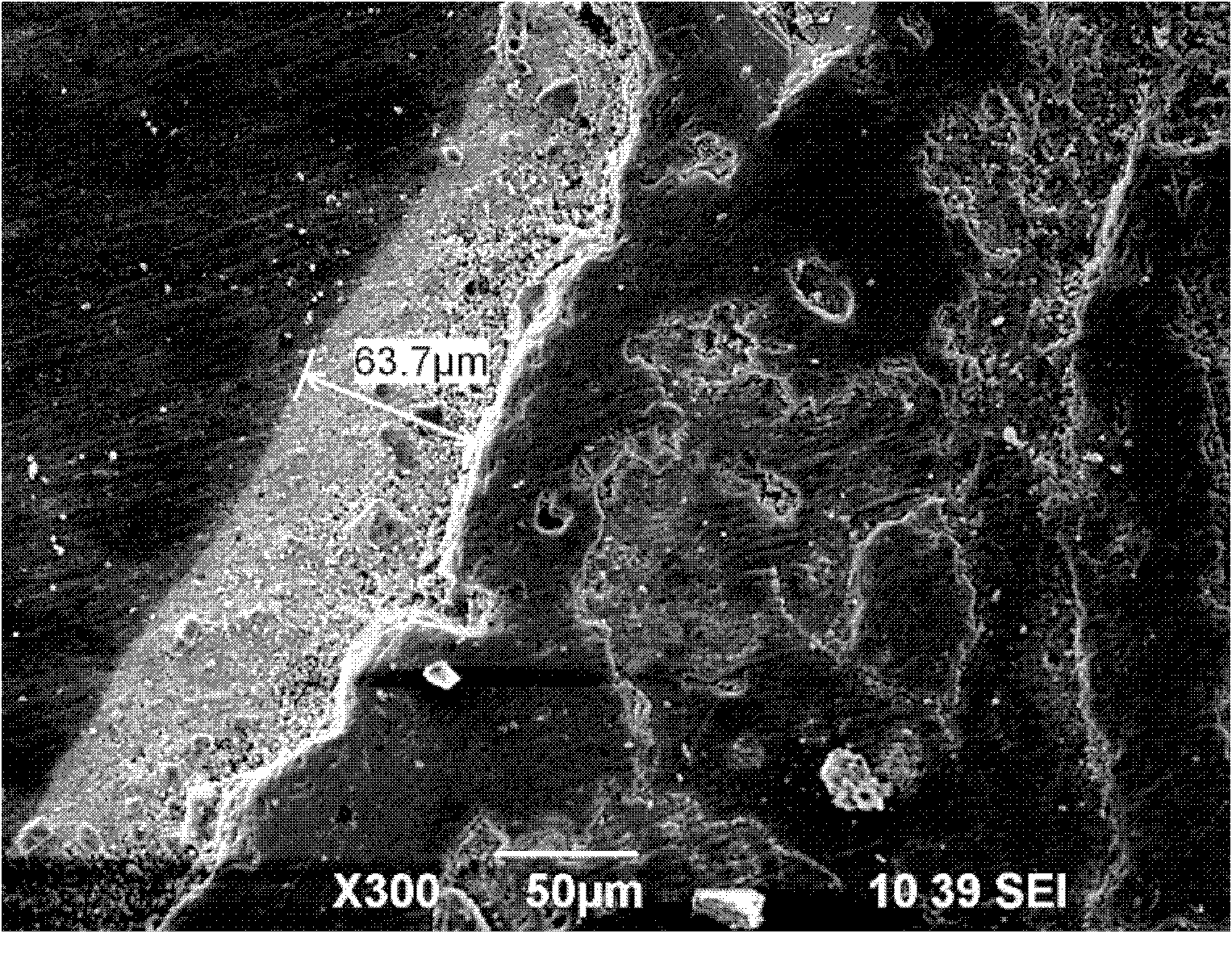

Embodiment 1

[0012] Embodiment 1: 1) get 5ml SiO 2 The content is greater than or equal to 28% tetraethyl orthosilicate, 20ml of absolute ethanol and 10ml of distilled water are mixed evenly, and then the pH value of the solution is adjusted to 4 with hydrochloric acid, and magnetically stirred for 1 hour at room temperature to prehydrolyze the tetraethyl orthosilicate to obtain ethyl orthosilicate Ester solution; 2) get 25.12g of analytically pure Al(NO 3 ) 3 9H 2 Al(NO 3 ) 3 aqueous solution; 3) the Al(NO) prepared in step 2) 3 ) 3The aqueous solution is mixed with the tetraethyl orthosilicate solution prepared in step 1), and then magnetically stirred at room temperature for 2-4 hours to obtain a sol. During this process, the pH value of the sol is adjusted to 4.5 with ammonia water at pH=10.7; 4) Take 5 g of the average particle size of 40nm The nano-SiC powder is dispersed in the sol and ultrasonically dispersed by an ultrasonic generator with a power of 100-300W so that the nan...

Embodiment 2

[0016] Embodiment 2: 1) get 5ml SiO 2 The content is greater than or equal to 28% ethyl orthosilicate, 20ml of absolute ethanol and 10ml of distilled water are mixed evenly, and then the pH value of the solution is adjusted to 3 with hydrochloric acid, and magnetically stirred for 40 minutes at room temperature to pre-hydrolyze ethyl orthosilicate to obtain ethyl orthosilicate Ester solution; 2) get 25.12g of analytically pure Al(NO 3 ) 3 9H 2 Al(NO 3 ) 3 aqueous solution; 3) the Al(NO) prepared in step 2) 3 ) 3 The aqueous solution is mixed with the tetraethyl orthosilicate solution prepared in step 1), and then magnetically stirred at room temperature for 2-4 hours to obtain a sol. During this process, the pH value of the sol is adjusted to 5 with ammonia water at pH=10.7; 4) Take 6 g of the average particle size of 40nm The nano-SiC powder is dispersed in the sol and ultrasonically dispersed by an ultrasonic generator with a power of 100-300W so that the nano-SiC powd...

Embodiment 3

[0017] Embodiment 3: 1) get 5ml SiO 2 The content is greater than or equal to 28% tetraethyl orthosilicate, 20ml of absolute ethanol and 10ml of distilled water are mixed evenly, and then the pH value of the solution is adjusted to 2 with hydrochloric acid, and magnetically stirred for 1 hour at room temperature to prehydrolyze the tetraethyl orthosilicate to obtain ethyl orthosilicate Ester solution; 2) get 25.12g of analytically pure Al(NO 3 ) 3 9H 2 O was dissolved in 20ml of distilled water and stirred magnetically for 30min at room temperature 3 ) 3 aqueous solution; 3) the Al(NO) prepared in step 2) 3 ) 3 Mix the aqueous solution with the tetraethyl orthosilicate solution prepared in step 1) and then magnetically stir at room temperature for 2-4 hours to obtain a sol. During this process, adjust the pH value of the sol to 4.5 with ammonia water at pH=10.7; 4) take 7 g of the average particle size of 40nm The nano-SiC powder is dispersed in the sol, and an ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com