High temperature, high efficiency thermoelectric module

A thermoelectric module and high-temperature technology, which is applied in thermoelectric device parts, manufacturing/processing of thermoelectric devices, thermoelectric device junction lead-out materials, etc., can solve problems such as degradation performance and cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] first preferred embodiment

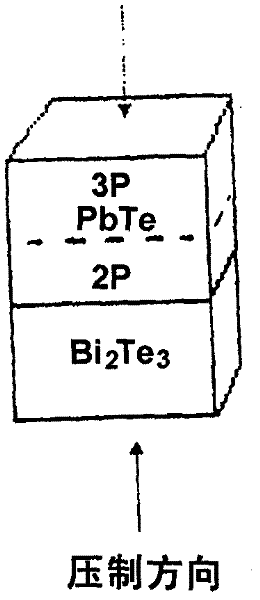

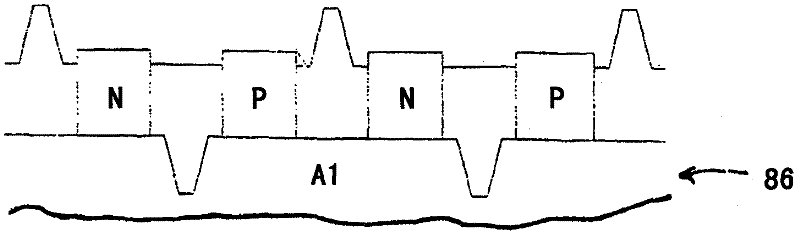

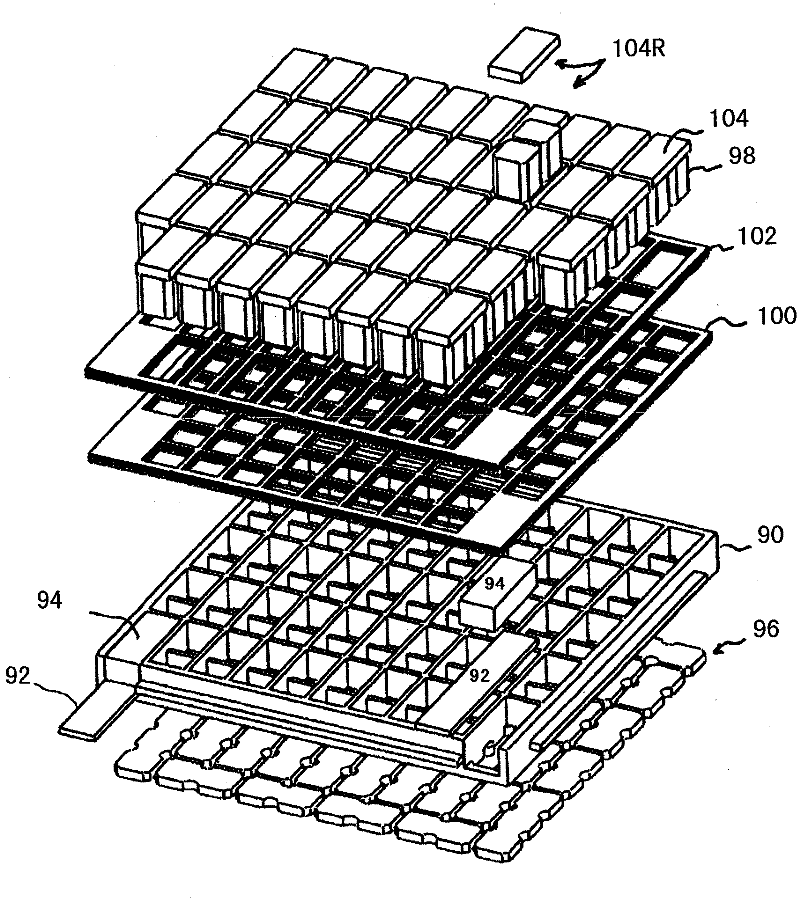

[0065] The first preferred embodiment of the present invention can be seen by referring to the attached Figure 4 , 4A and 7 to describe. Figure 4 and 4A From parent application S / N.12 / 317,170, but this first preferred module is a substantially improved and more efficient version of the embodiment described in the parent application, which is hereby incorporated by reference. For example, a significant difference is that the first preferred embodiment of the present application uses three segmented thermoelectric legs in the module instead of only two segments. Specifically, for this preferred embodiment, Figure 4 and Figure 4A Each of the segments 72a and 74a shown in is composed of two types of lead telluride material instead of only one type as in the parent application. exist Figure 7 This preferred embodiment is shown in more detail in , where the two types of lead telluride material in each pin are cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com