Aqueous epoxy antistatic coating with nano-core-shell structural conductive polyaniline and preparation method thereof

A conductive polyaniline and nano-core-shell technology, applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of polyaniline inability to melt, poor mechanical properties, and easy precipitation, etc., to achieve low cost and high conductivity Controllable, excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of a water-based epoxy antistatic coating containing nano-core-shell conductive polyaniline

[0027] Use epoxy resin (E-44) and polyethylene glycol (PEG-4000) as raw materials, control the molar ratio of epoxy resin and polyethylene glycol to be 1:1, and use the catalyst as AlCl 3 (the amount of catalyst used is 0.5% of the total mass of epoxy resin and polyethylene glycol), the reaction temperature is controlled at 100° C., and the reaction is carried out for 6 hours to prepare a self-made emulsifier for future use.

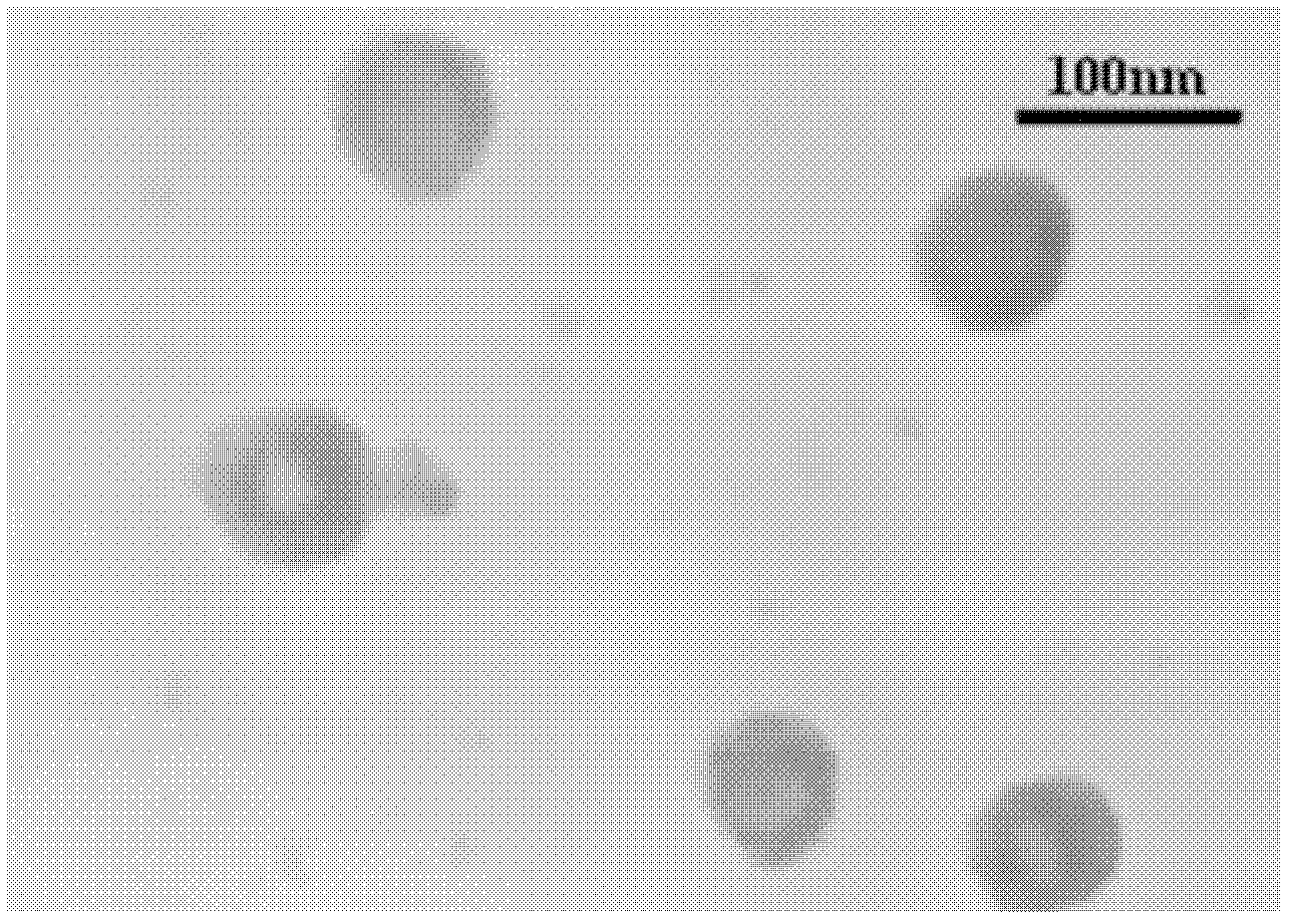

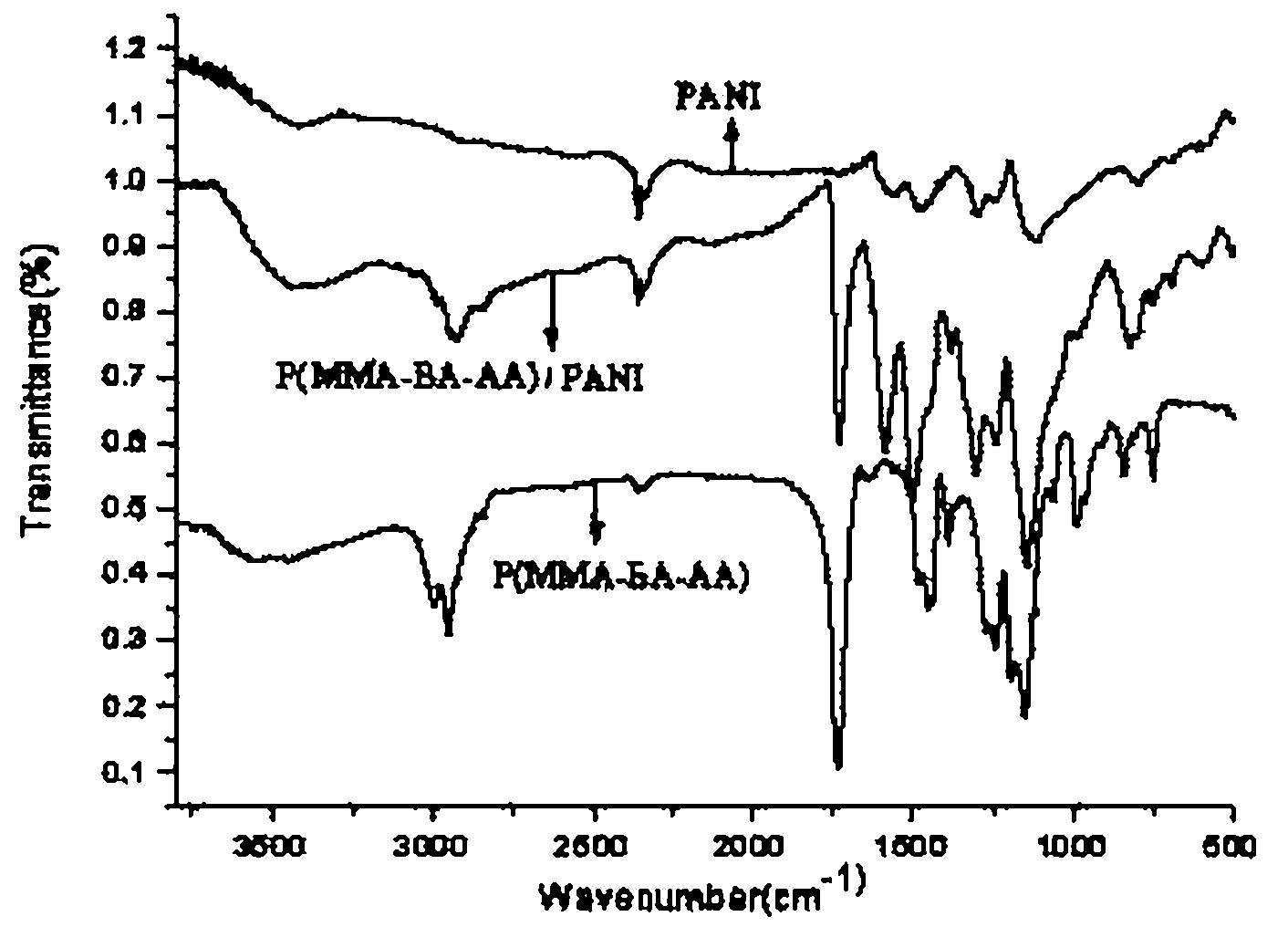

[0028] In a round bottom flask, dissolve 0.75g sodium dodecylsulfonate and 0.75g self-made emulsifier in 60g deionized water, and stir vigorously for 1 hour until completely dissolved. Add 7.5g of methyl methacrylate, 1.5g of butyl acrylate, and 0.375g of acrylic acid and continue magnetic stirring for 20 minutes to obtain a uniformly stirred pre-emulsion. Put the pre-emulsion into an ultrasonic cleaner filled with ice water and so...

Embodiment 2

[0030] Example 2: Preparation of a water-based epoxy antistatic coating containing nano-core-shell conductive polyaniline

[0031] Use epoxy resin (E-44) and polyethylene glycol (PEG-4000) as raw materials, control the molar ratio of epoxy resin and polyethylene glycol to be 1:1, and use the catalyst as AlCl 3 (the amount of catalyst used is 1% of the total mass of epoxy resin and polyethylene glycol), the reaction temperature is controlled at 120° C., and the reaction is carried out for 8 hours to prepare a self-made emulsifier for future use.

[0032] Dissolve 1.12g of sodium dodecylsulfonate and 1.12g of self-made emulsifier in 60g of deionized water in a round bottom flask, and stir vigorously for 1 hour until completely dissolved. Add 15 g of methyl methacrylate, 3 g of butyl acrylate, and 0.75 g of acrylic acid and continue magnetic stirring for 20 minutes to obtain a uniformly stirred pre-emulsion. Put the pre-emulsion into an ultrasonic cleaner filled with ice water and...

Embodiment 3

[0034] Example 3: Preparation of a water-based epoxy antistatic coating containing conductive polyaniline with nano-core-shell structure

[0035] Use epoxy resin (E-44) and polyethylene glycol (PEG-4000) as raw materials, control the molar ratio of epoxy resin and polyethylene glycol to be 1:1, and use the catalyst as AlCl 3 (the amount of catalyst used is 1% of the total mass of epoxy resin and polyethylene glycol), the reaction temperature is controlled at 120° C., and the reaction is carried out for 8 hours to prepare a self-made emulsifier for future use.

[0036] Dissolve 1.02g of sodium dodecylsulfonate and 1.22g of self-made emulsifier in 67.5g of deionized water in a round bottom flask, and stir vigorously for 1 hour until completely dissolved. Add 11.25g methyl methacrylate, 2.25g butyl acrylate, 0.45g acrylic acid and continue magnetic stirring for 20min to obtain a uniformly stirred pre-emulsion. Put the pre-emulsion into an ultrasonic cleaner filled with ice water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com