Organic pollutant-resistant polymer bentonite nanocomposite material and preparation method thereof

A technology of nano-composite materials and organic pollutants, which is applied in the fields of civil engineering and environmental geotechnical engineering, can solve the problems of reduced chemical compatibility, weakened chemical compatibility, anti-seepage characteristics, etc., and achieves simple and easy-to-operate preparation methods, Broad application prospects and environmental protection significance, the effect of low permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

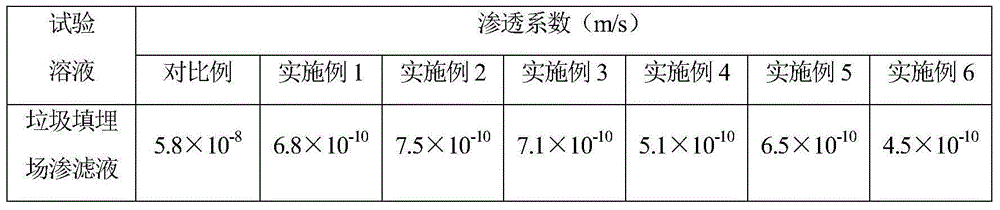

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned polymer bentonite nanocomposite material resistant to organic pollutants comprises the following steps:

[0025] Step 10) mix bentonite and water, and stir with a mixer to prepare bentonite slurry.

[0026] In step 10), preferably, bentonite and water are prepared at a mass ratio of 0.1-0.2:1. Before mixing bentonite with water, pass through a 200-mesh sieve to remove impurities. The bentonite is passed through a 200-mesh sieve to make the particle size not greater than 0.15mm. The rotating speed of the mixer is 500-3000r / min, and the stirring time of the mixer is 5-15min.

[0027] Step 20) Add cationic polyacrylamide solution to the bentonite slurry and stir to form a mixed slurry of cationic polyacrylamide and bentonite.

[0028] In step 20), preferably, the cationic polyacrylamide in the cationic polyacrylamide solution accounts for 0.1-10% of the bentonite mass in the bentonite slurry. The cationic polyacrylamide is ...

Embodiment 1

[0037] Step 10) Pass the calcium-based bentonite through a 200-mesh sieve, mix the bentonite and water, prepare the bentonite and water according to the mass ratio of 0.1:1, stir with a mixer, the speed of the mixer is 2000r / min, and the mixing time is 10min to obtain bentonite mud.

[0038] Step 20) Add cationic polyacrylamide solution to the bentonite slurry and stir, the mass of cationic polyacrylamide accounts for 0.1% of the mass of bentonite in the bentonite slurry to form a mixed slurry of cationic polyacrylamide and bentonite. Among them, the molecular weight of cationic polyacrylamide is 5×10 6 .

[0039] Step 30) Put the cationic polyacrylamide and bentonite mixed slurry in a constant temperature water bath, the water temperature in the constant temperature water bath is 55°C, and stir the cationic polyacrylamide and bentonite mixed slurry at a speed of 200r / min for 4 hours. The cationic polyacrylamide undergoes a nano-intercalation reaction between the bentonite l...

Embodiment 2

[0042] Step 10) Pass the calcium-based bentonite through a 200-mesh sieve, mix the bentonite and water, prepare the bentonite and water according to the mass ratio of 0.2:1, stir with a mixer, the speed of the mixer is 500r / min, and the mixing time is 15min to obtain bentonite mud.

[0043] Step 20) Add cationic polyacrylamide solution to the bentonite slurry and stir, the mass of cationic polyacrylamide accounts for 1% of the mass of bentonite in the bentonite slurry to form a mixed slurry of cationic polyacrylamide and bentonite. Among them, the molecular weight of cationic polyacrylamide is 8×10 6 .

[0044] Step 30) Put the cationic polyacrylamide and bentonite mixed slurry in a constant temperature water bath, the water temperature in the constant temperature water bath is 60°C, stir the cationic polyacrylamide and bentonite mixed slurry at a speed of 1200r / min for 3 hours, The cationic polyacrylamide undergoes a nano-intercalation reaction between the bentonite layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com