Novel inner circular seam automatic welding mechanism for cylinder assembly

An automatic welding and inner circumferential seam technology, applied in the field of welding boilers and pressure vessels, can solve the problems of low efficiency, high labor intensity and high welding seam repair rate, and achieve the effects of high efficiency, small workload and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

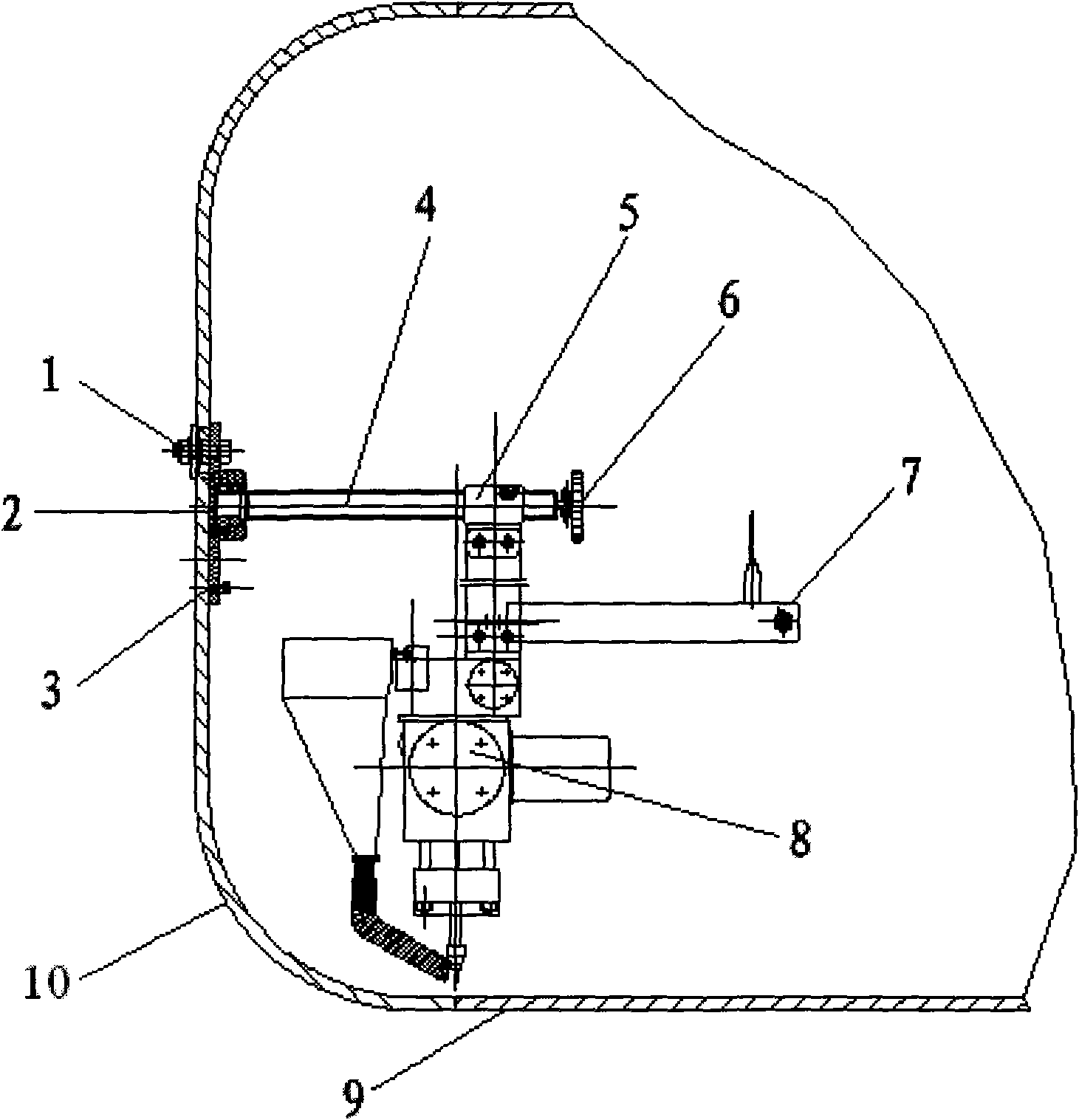

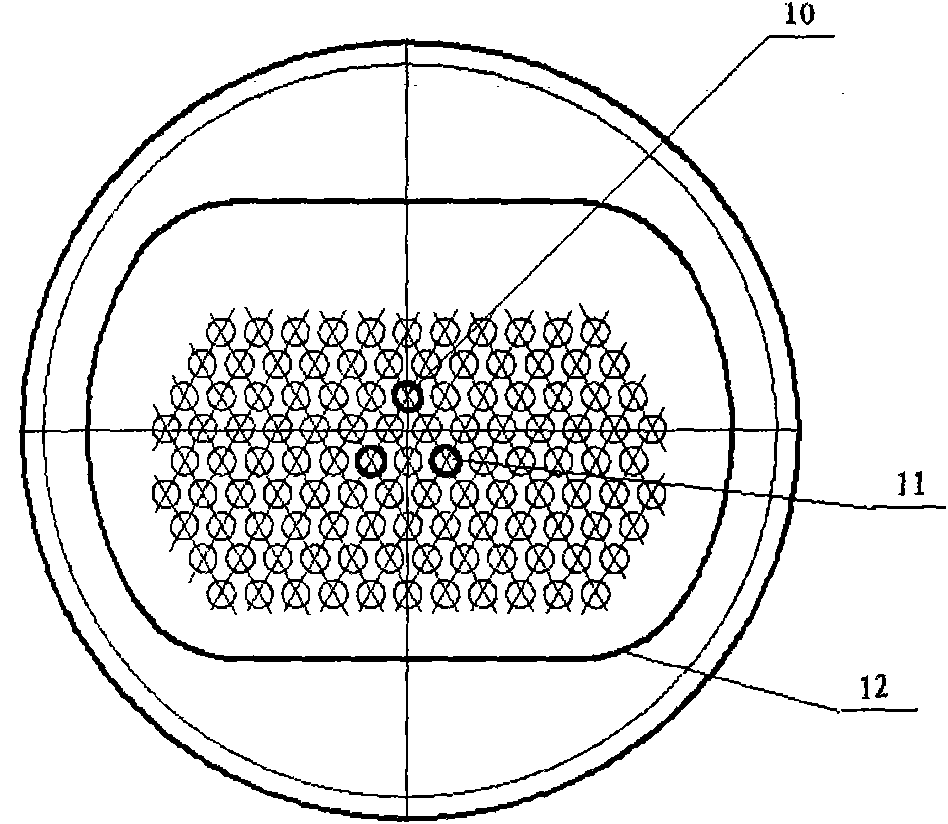

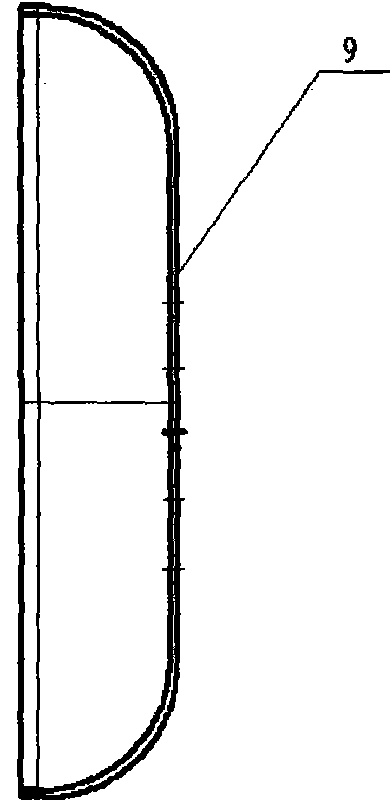

[0011] Three head holes (11) are selected on the arched tube sheet head (10) as positioning datums. Through the positioning backing plate (12) of three head holes (11), the base plate on the positioning bearing seat (1) is positioned and connected with the arched tube plate head (10) with bolts (2). The cantilever screw (4) is installed on the positioning bearing seat (1), and is guaranteed to be coaxial with the head cylinder (9). The suspension type submerged arc welding machine head (8) is fixed on the nut connecting plate (5). When the handwheel (6) is turned, the nut connecting plate (5) drives the suspended submerged arc welding head (8) and the welding wire reel support (7) to move axially. When the positioning bearing seat (1) is rotated and welded with the cylinder (9), the shaft of the cantilever screw (4) is relatively stable, which is satisfactory for automatic welding. The suspended submerged arc welding machine head (8) and accessories enter the cylinder body (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com