Gas impermeable tube joint and method of forming same

a technology of impermeable tube joints and gas, which is applied in the direction of hose connections, other domestic objects, mechanical instruments, etc., can solve the problems of gas infiltration and exfiltration, the amount of fuel vapor that may escape, and the danger to the environment of fuel vapor escape from the fuel fill system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

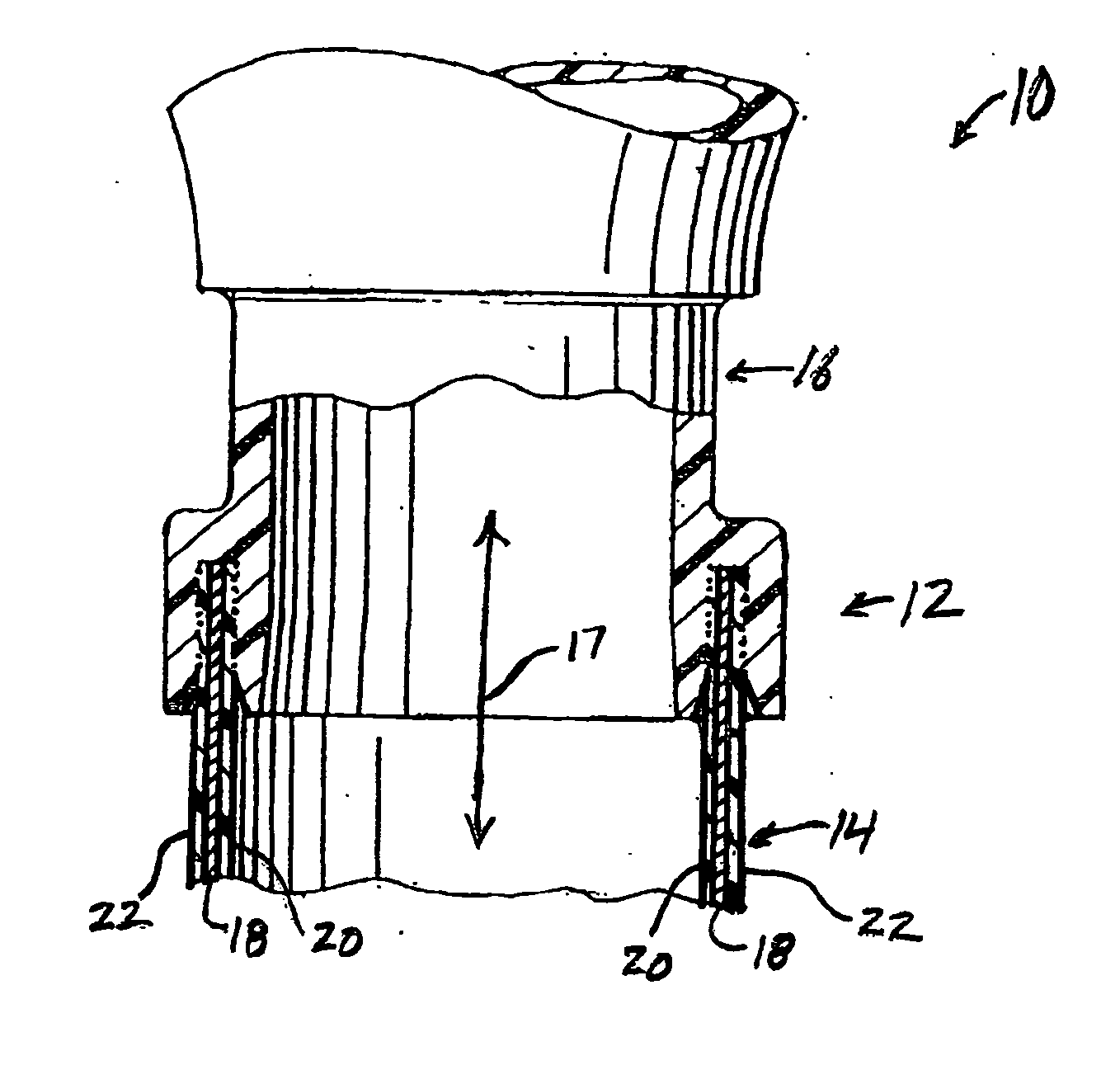

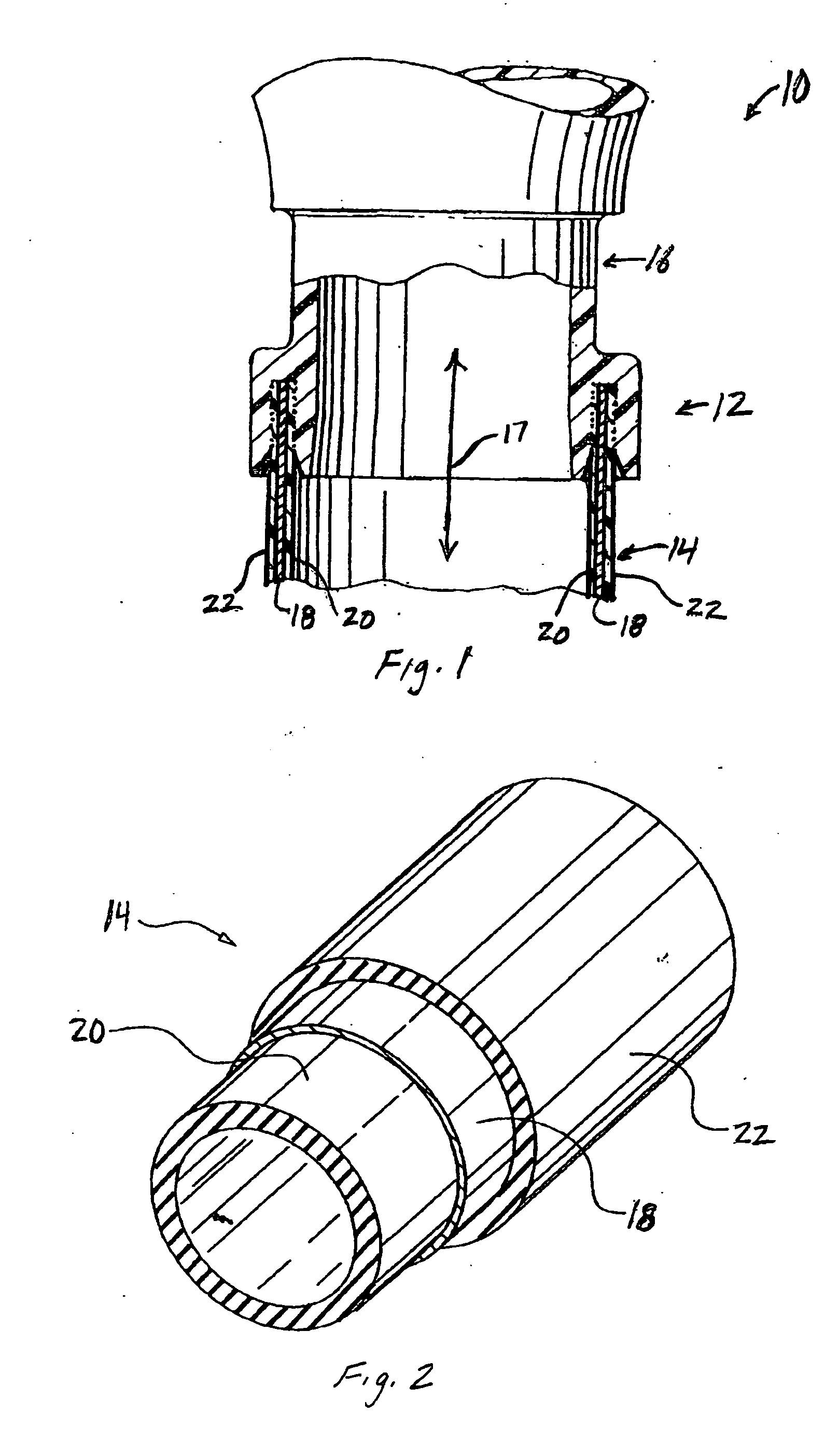

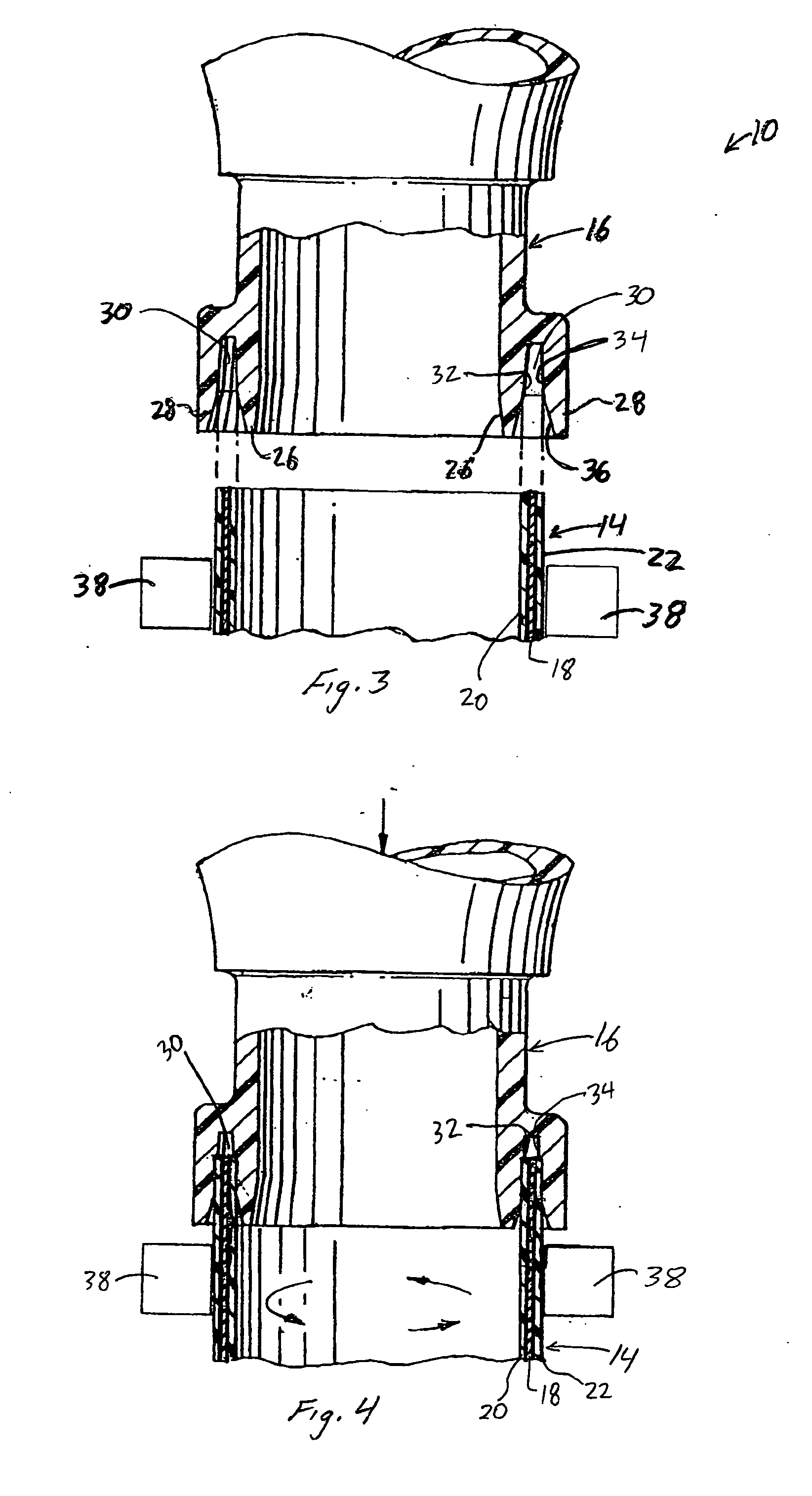

[0029]FIG. 1 is a partial cross-sectional view of a portion of a fluid system 10 including a gas impermeable tube joint 12. The fluid system 10 includes a tube 14 having an end coupled to a component 16 via the joint 12, which allows fluid to be communicated between the tube 14 and the component 16 as indicated by arrow 17. The component 16 may be any component in the fluid system 10 such as, for example a pump, funnel, tank, heat exchanger, valve, tube-to-tube coupling, flange, quick disconnect coupling, filter, and the like. For example, component 16 may be a funnel used within a fuel fill system in a motor vehicle, as described in commonly owned U.S. patent application Ser. No. ______ to Swane (Attorney Docket No. 02-13), filed concurrently herewith and entitled “Fuel Fill System”, which is incorporated by reference herein in its entirety. The component 16 may also be another tube. It will be appreciated that the fluid system 10 may include any number of joints 12 connecting tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com