Spin welding oil cup clamp capable of preventing welding oxidation and control method

A rotary welding and oil cup technology, which is applied in the control field of anti-welding and oxidation-proof rotary-welding oil-cup fixtures and anti-welding and oxidation-proof rotary-welding oil cup fixtures, can solve the problem of increasing production costs, reducing production efficiency, and unsightly welds, etc. problems, to achieve the effect of zero scrap rate, high production efficiency, and reliable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

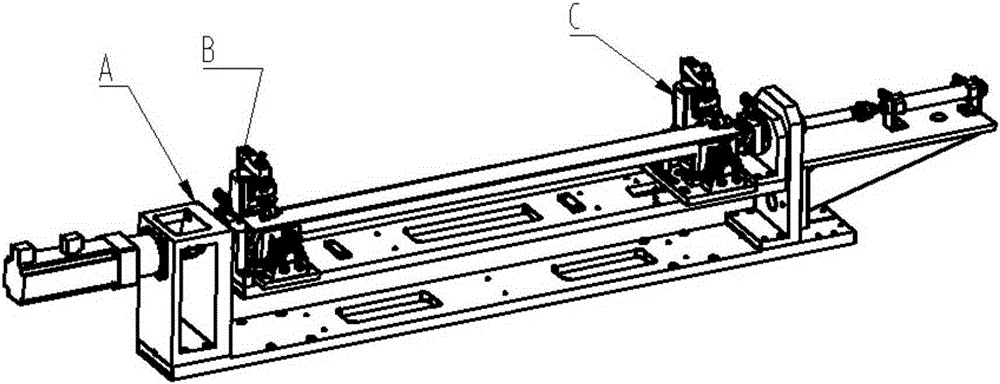

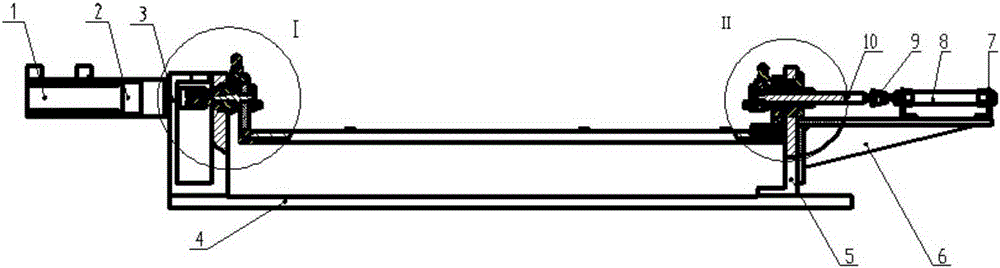

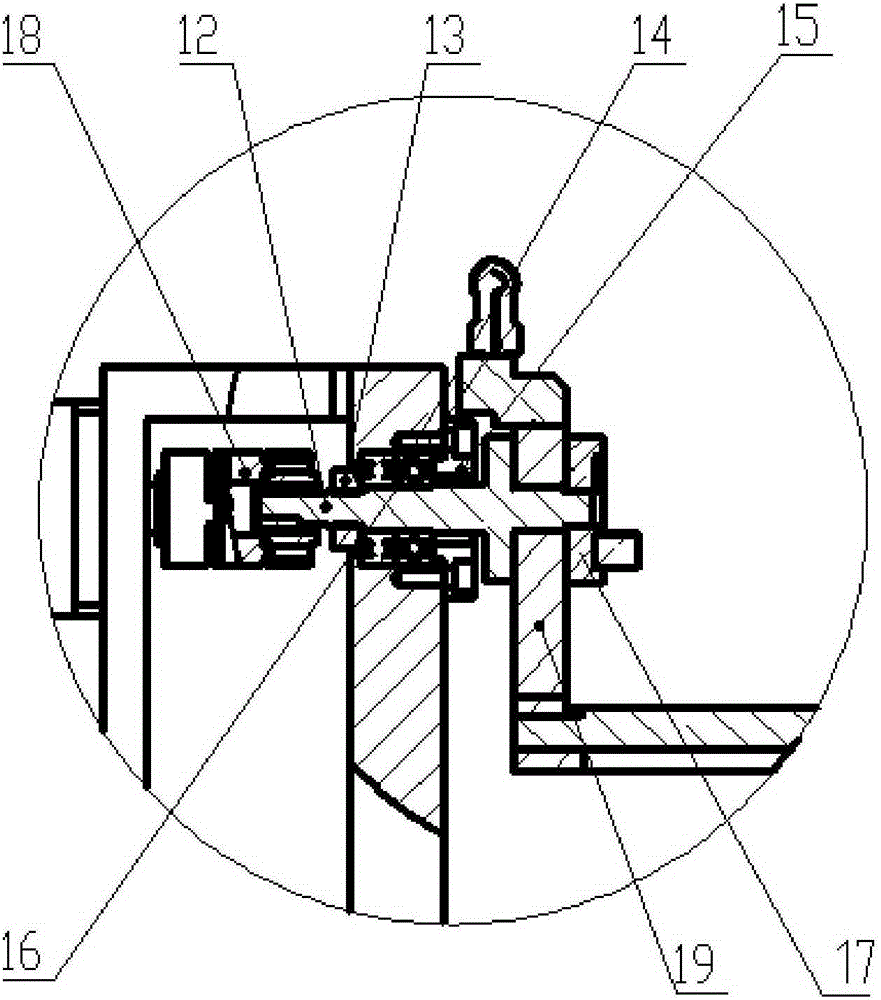

[0032] see figure 1 - Figure 9 , a kind of anti-welding oxidation rotary welding oil cup fixture of the present invention, comprises hanging basket part, left side clamping part, right side clamping part, protective gas channel, left side clamping part, right side clamping part are respectively installed On both sides of the hanging basket part, it plays the role of positioning and clamping. The shielding gas passage is located in the middle of the left clamping part and the right clamping part respectively. The shielding gas passage is used to blow out the shielding gas during welding to prevent the workpiece from being oxidized during welding. Discoloration, keep the surface of the workpiece clean, the oil cup workpiece is placed on the fixture, the left clamping part and the right clamping part position and clamp the workpiece at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com