Patents

Literature

30results about How to "Zero scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Helicopter composite material paddle fatigue test piece molding method

InactiveCN102507275AGuaranteed symmetryShorten the manufacturing cycleMachine part testingPreparing sample for investigationEngineeringRejection rate

The invention belongs to a composite material molding technology, and relates to helicopter composite material paddle fatigue test piece molding technological process which is suitable for helicopter composite material technological process molding. According to the invention, a platform thickness spacing tool is adopted, an interval between two splints of a paddle fatigue test piece is effectively ensured, and simultaneously the positioning of the spacing tool can insure symmetry of the two splints; and a working procedure of numerical control processing is directly omitted from a technical process, furthermore a manufacturing cycle is also shortened, once alternating detection qualification rate of the paddle fatigue test piece is improved, the rejection rate of the paddle fatigue test piece is zero, and the stability and the smoothness of the assembly process of the paddle fatigue test piece are ensured.

Owner:中航直升机股份有限公司

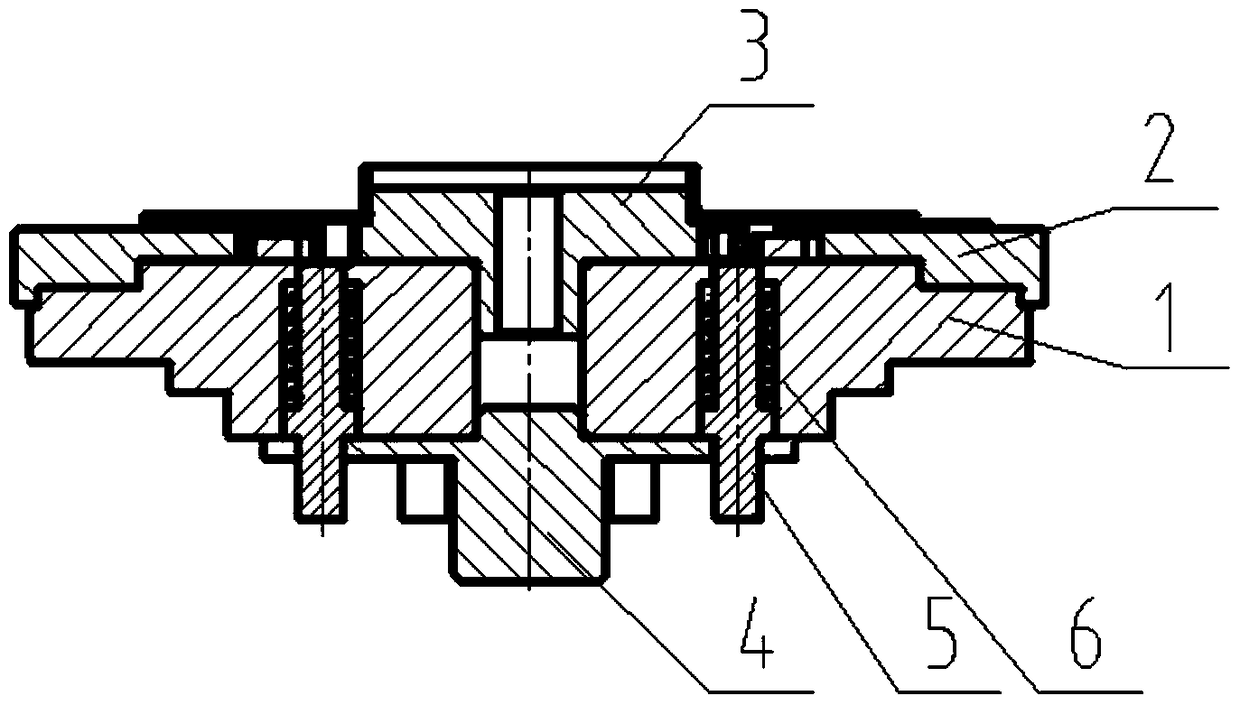

Vehicle shock absorber piston rod spraying technology

ActiveCN103147033AImprove bindingGood coating strengthMolten spray coatingWorking environmentPiston rod

The invention relates to a vehicle shock absorber piston rod spraying technology. The vehicle shock absorber piston rod spraying technology comprises the following steps of: coarse grinding, degreasing, surface roughening, non-spraying surface protection, preheating, spraying and fine grinding. When a piston rod is treated according to the spraying technology provided by the invention, the performances such as the binding force, the coating intensity, the coating thickness, the abrasion resistance, the corrosion resistance and the like of a coating of the piston rod are all superior to those of a durionise layer, and the cost performance of the coating is also superior to that of the durionise layer, so that the technology is a precedence technology used for replacing a durionise technology; and particularly, the technology does not pollute the environment, is beneficial to improvement of the working environment and the health and the safety of an operator. The technology has the advantages that production period is short, production efficiency is high, defective rate is low, the treated vehicle shock absorber piston rod has good rust-proof performance, good abrasion resistance and long service life; moreover, automation operation is easily realized, production efficiency is high and the production cost is lowered.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

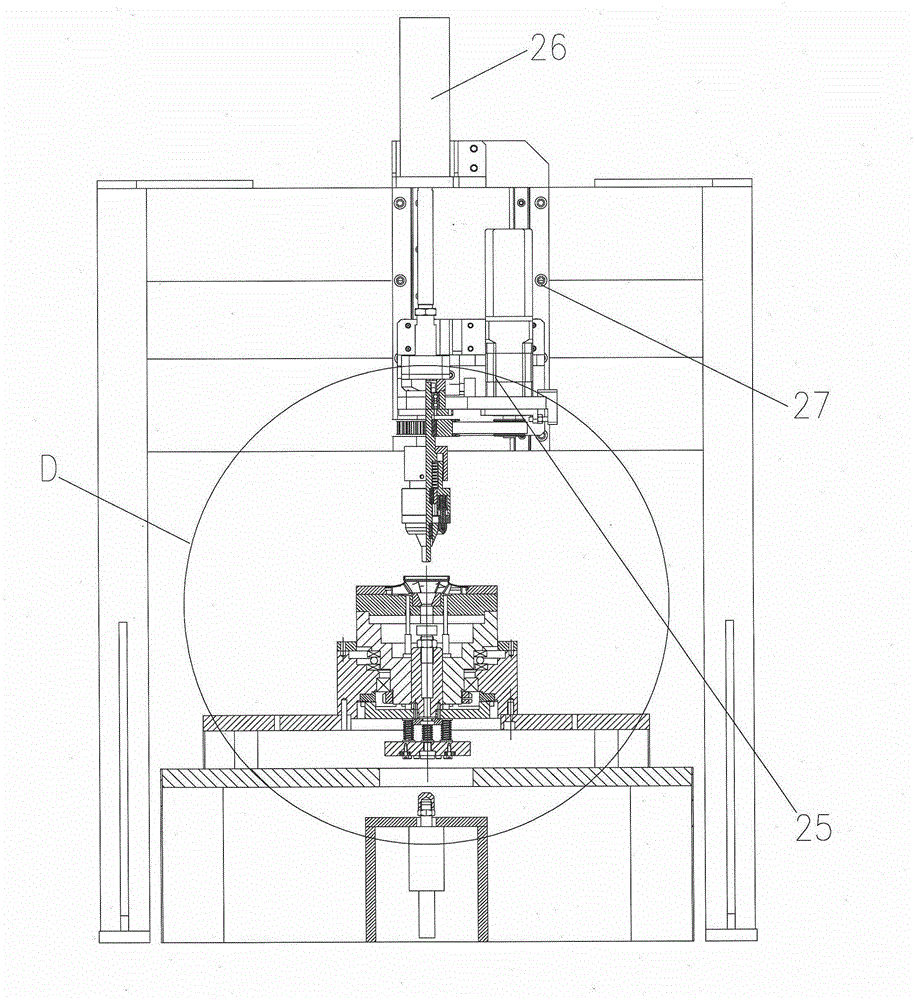

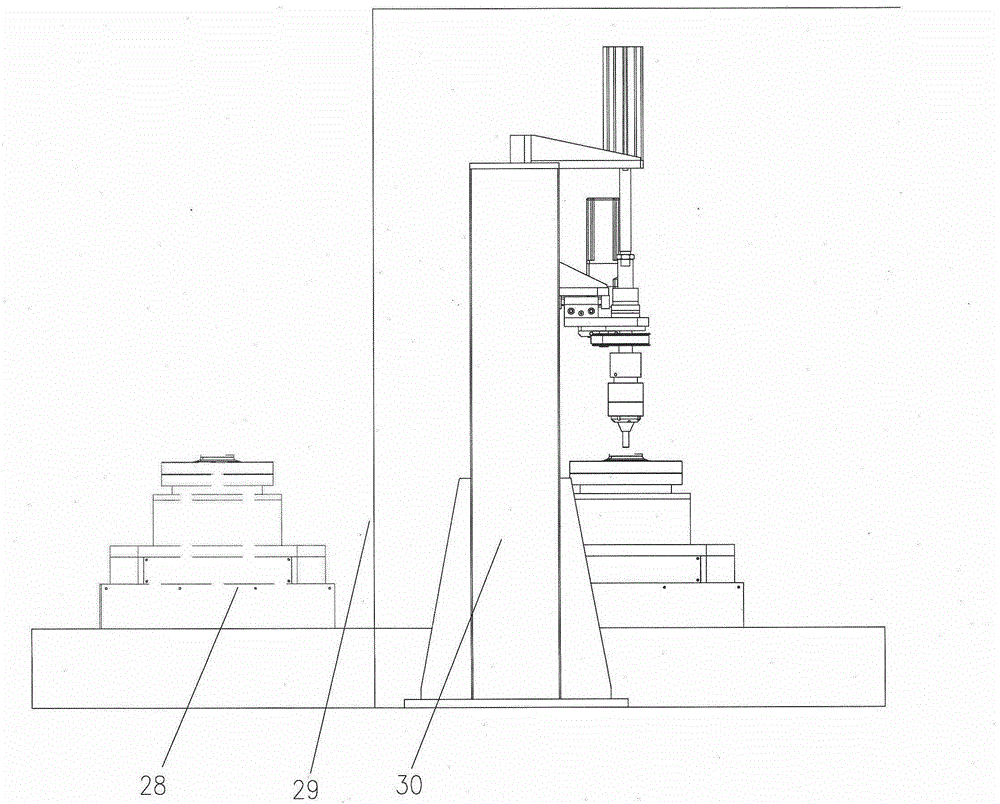

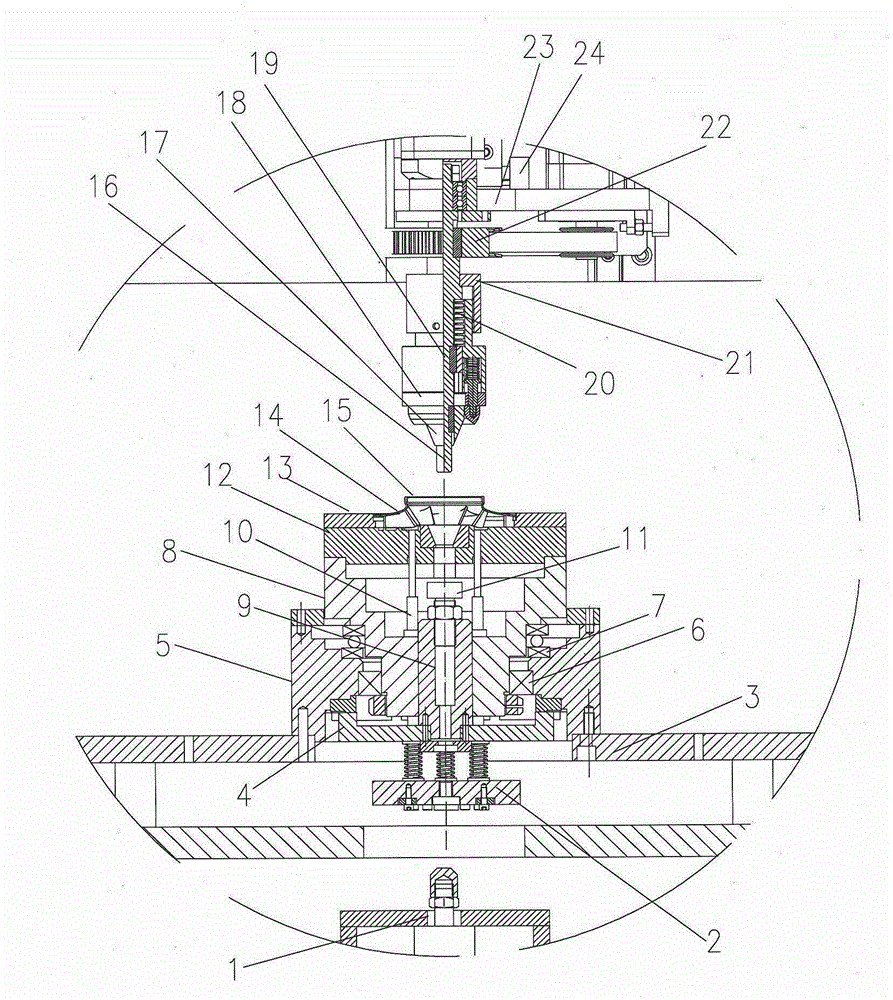

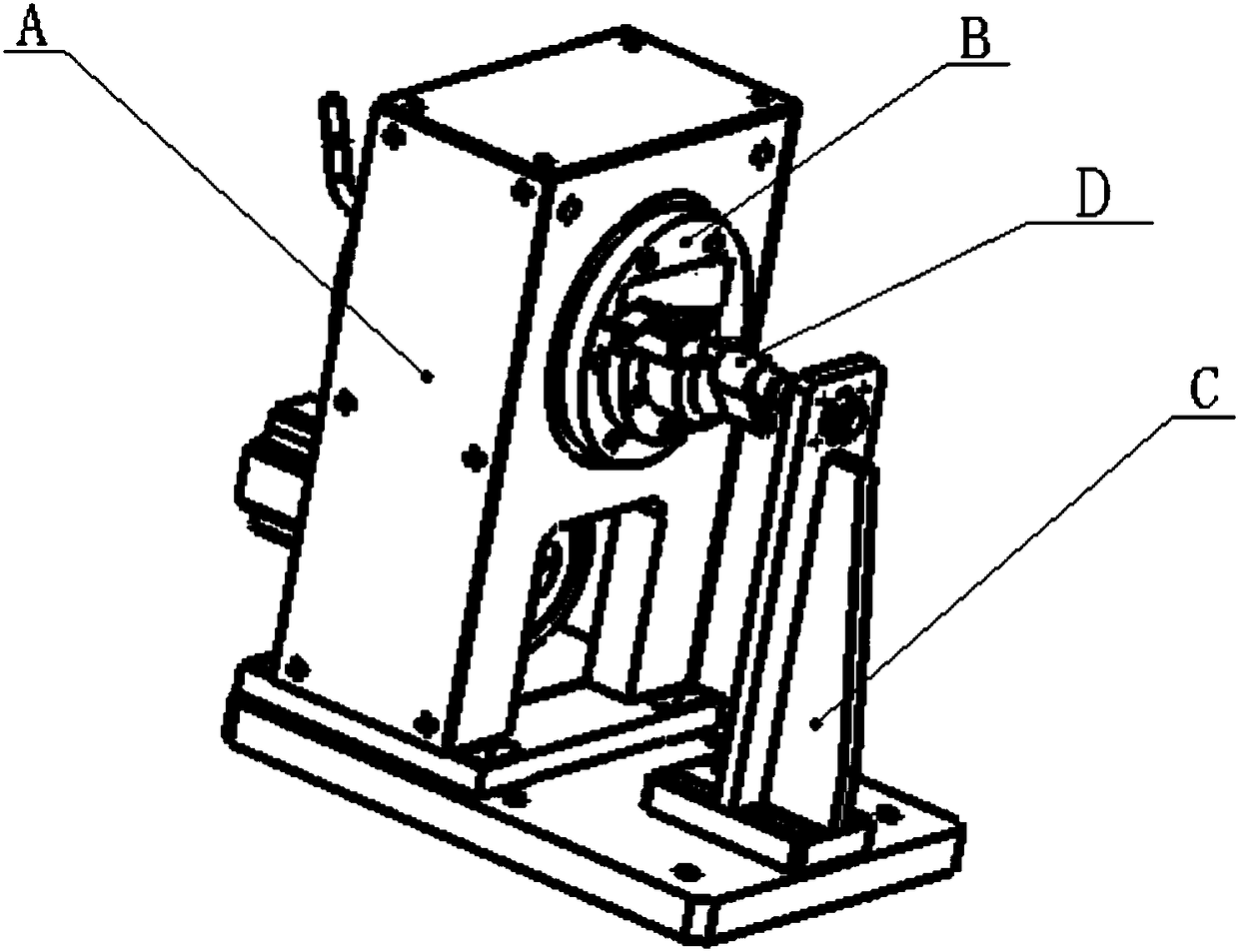

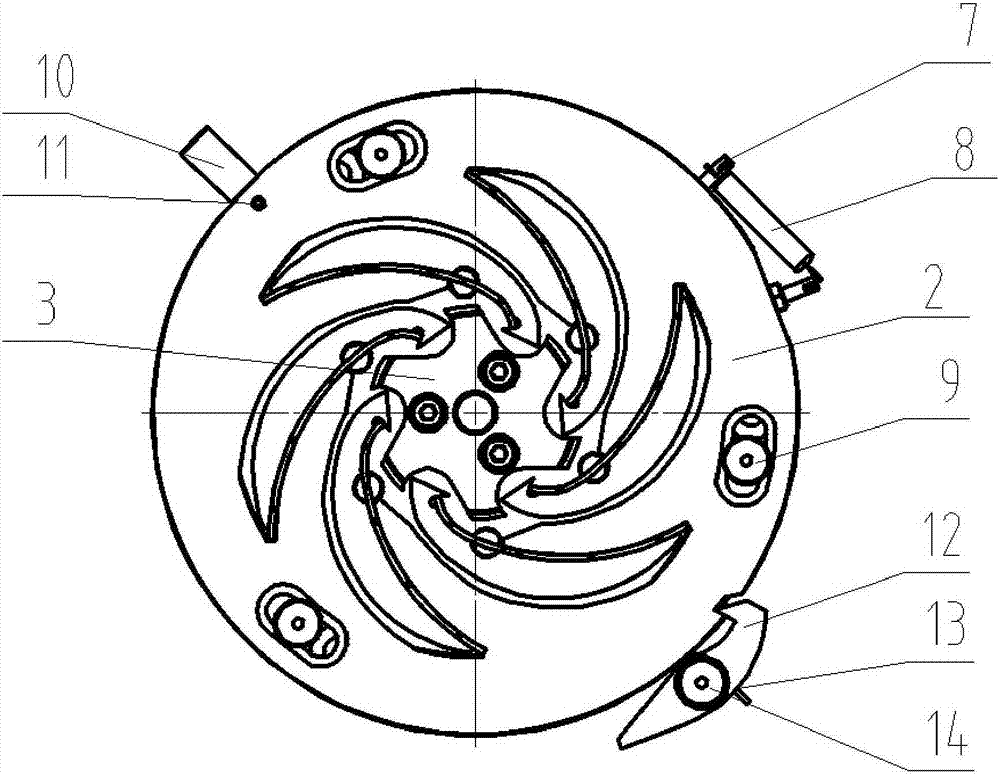

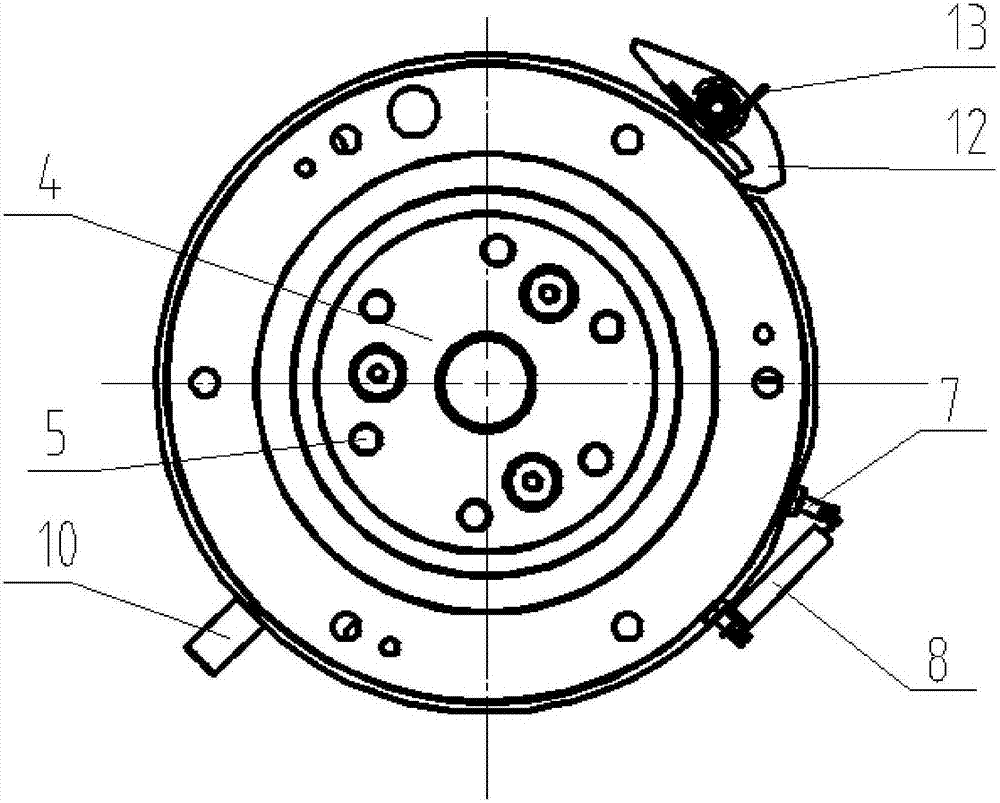

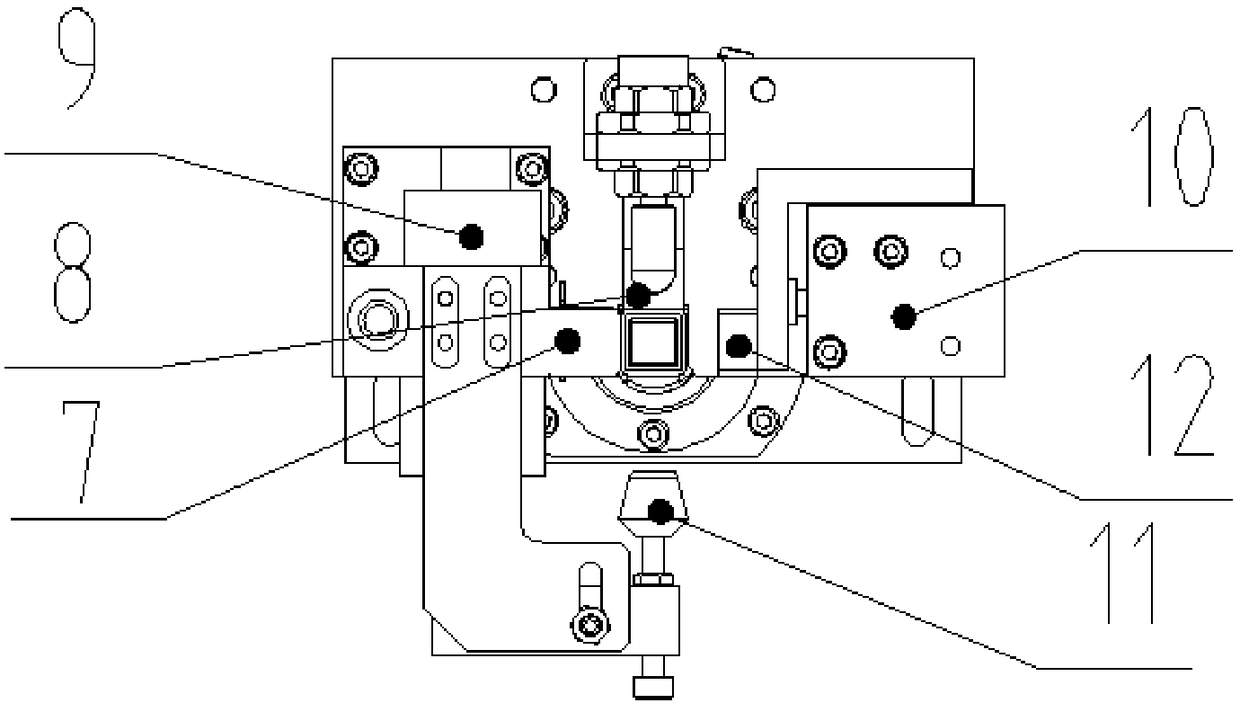

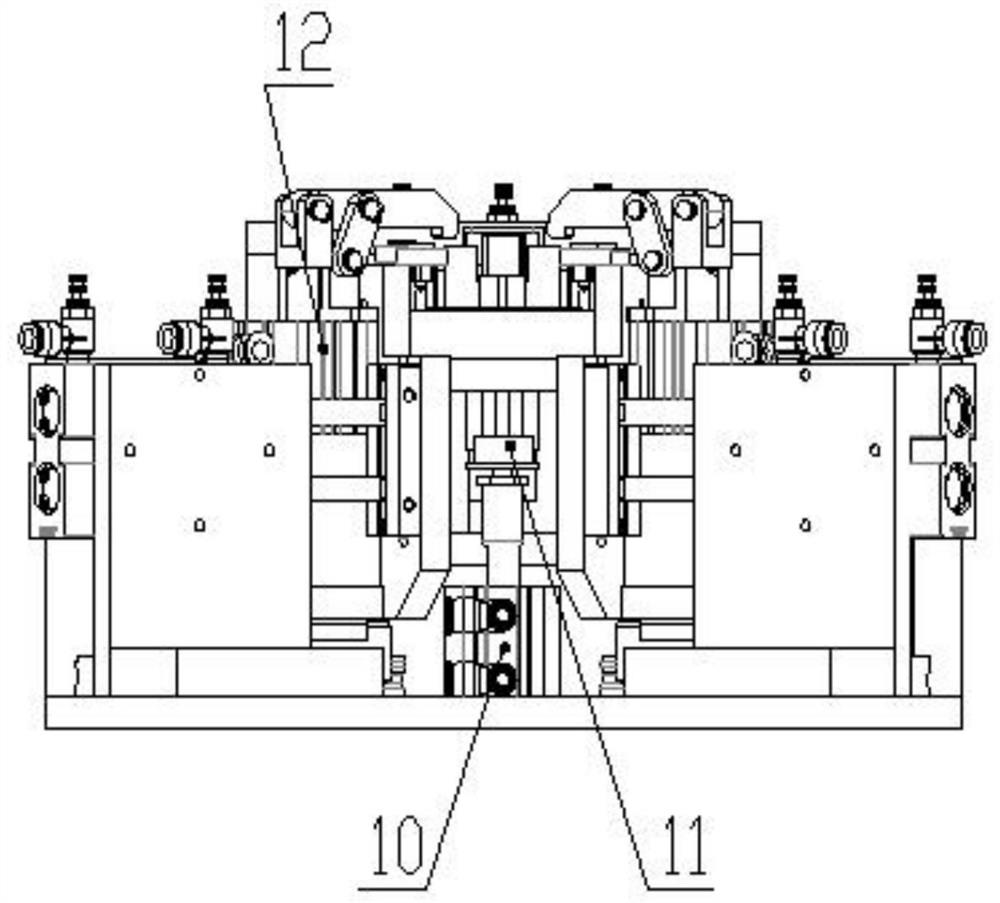

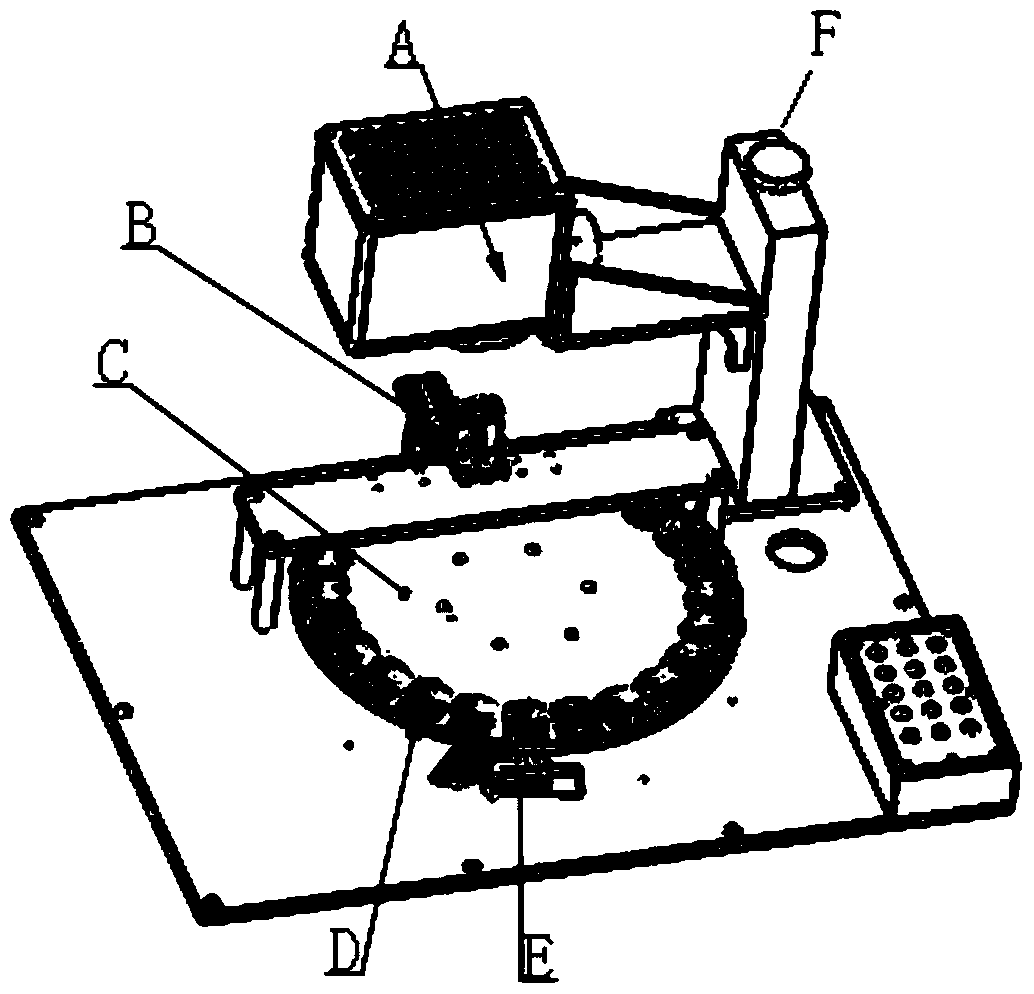

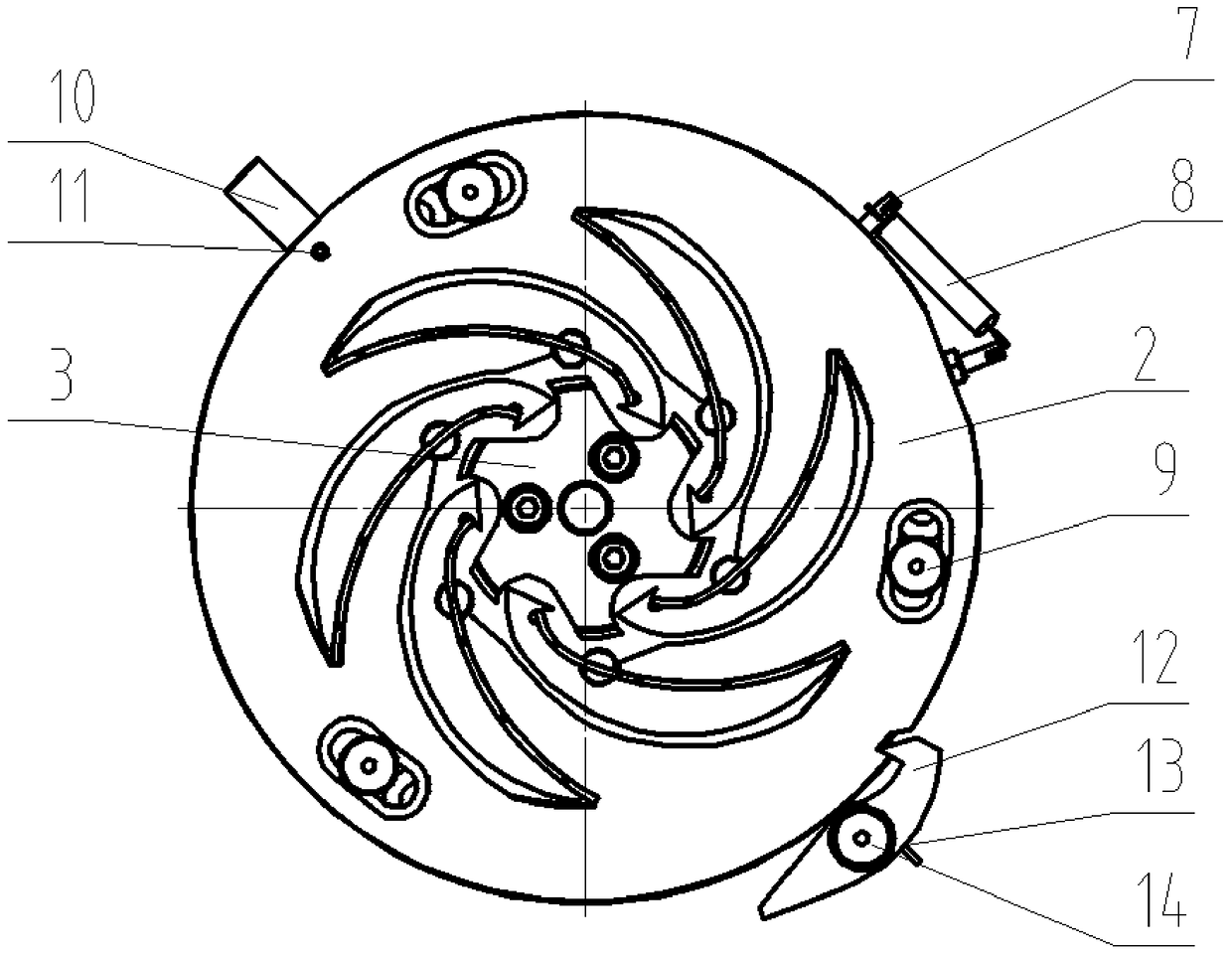

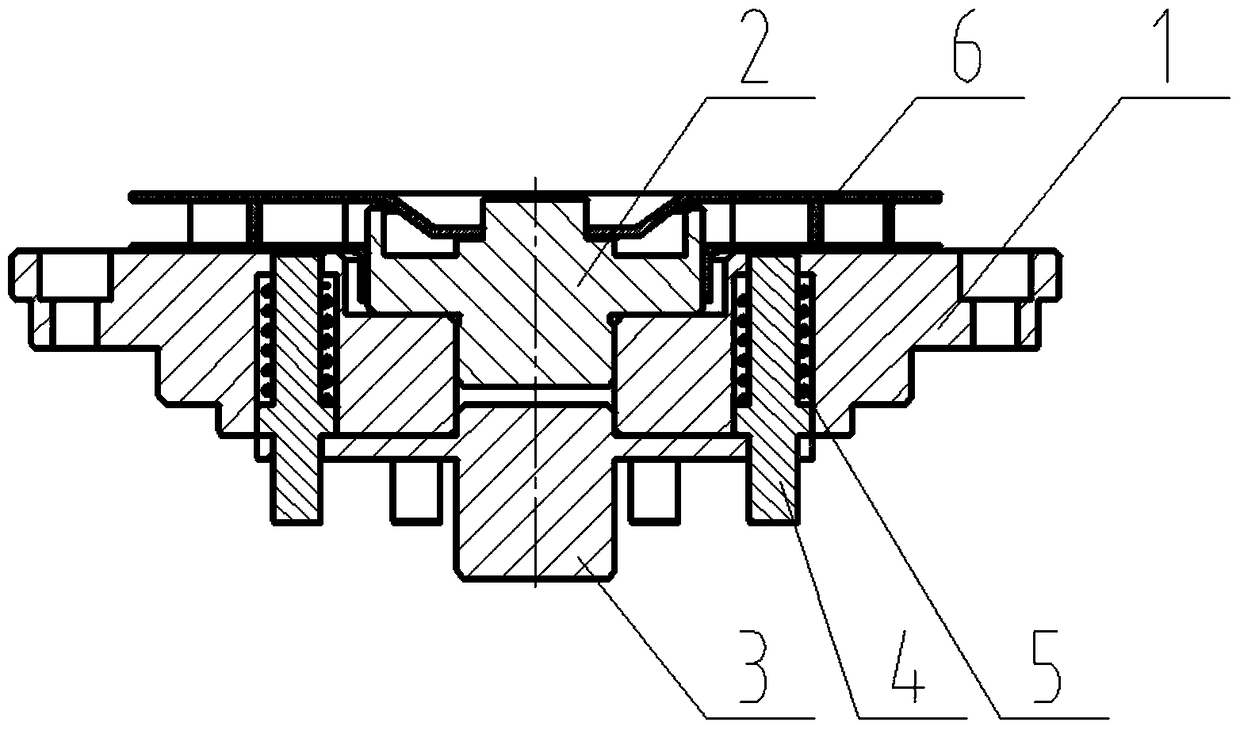

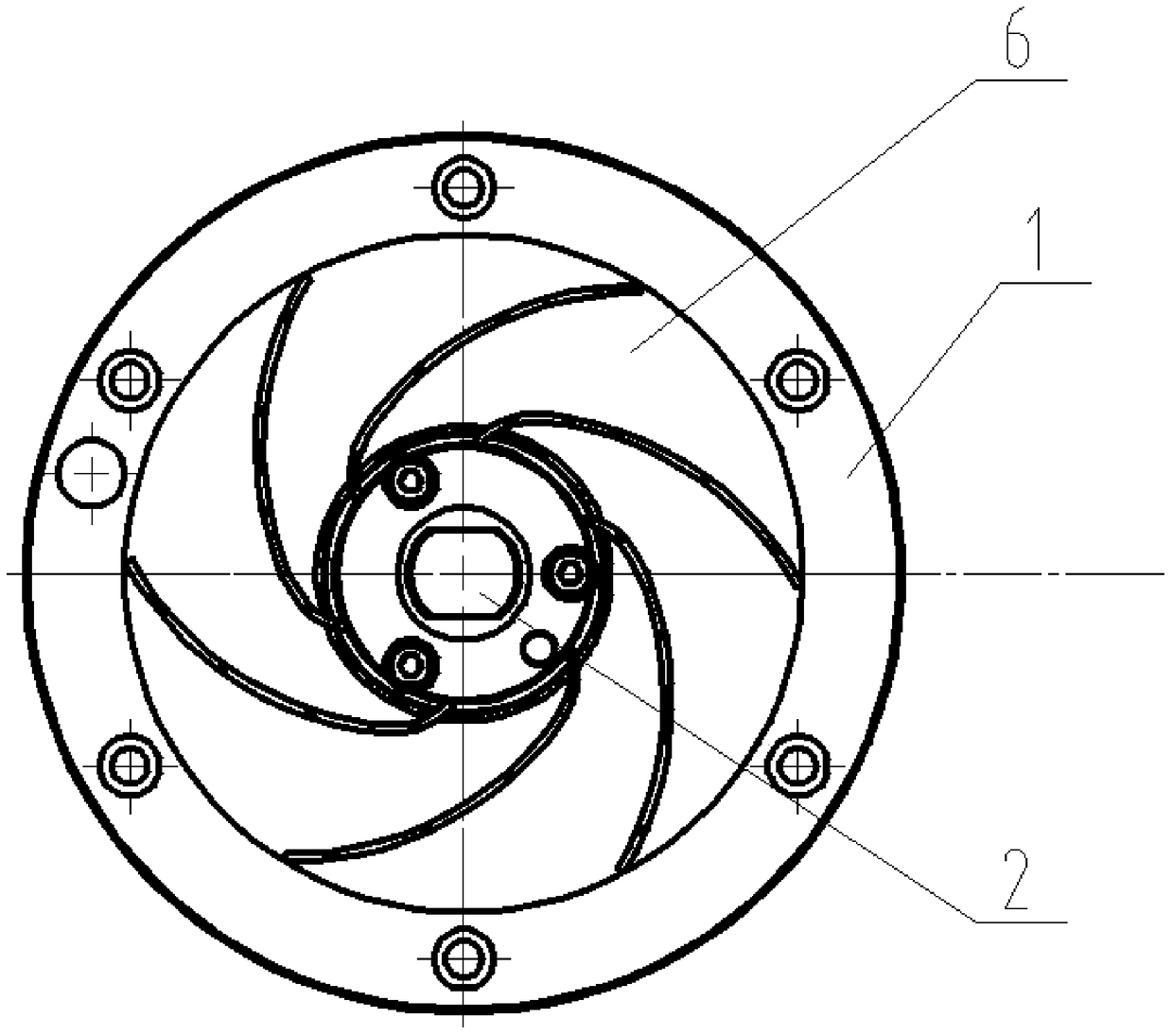

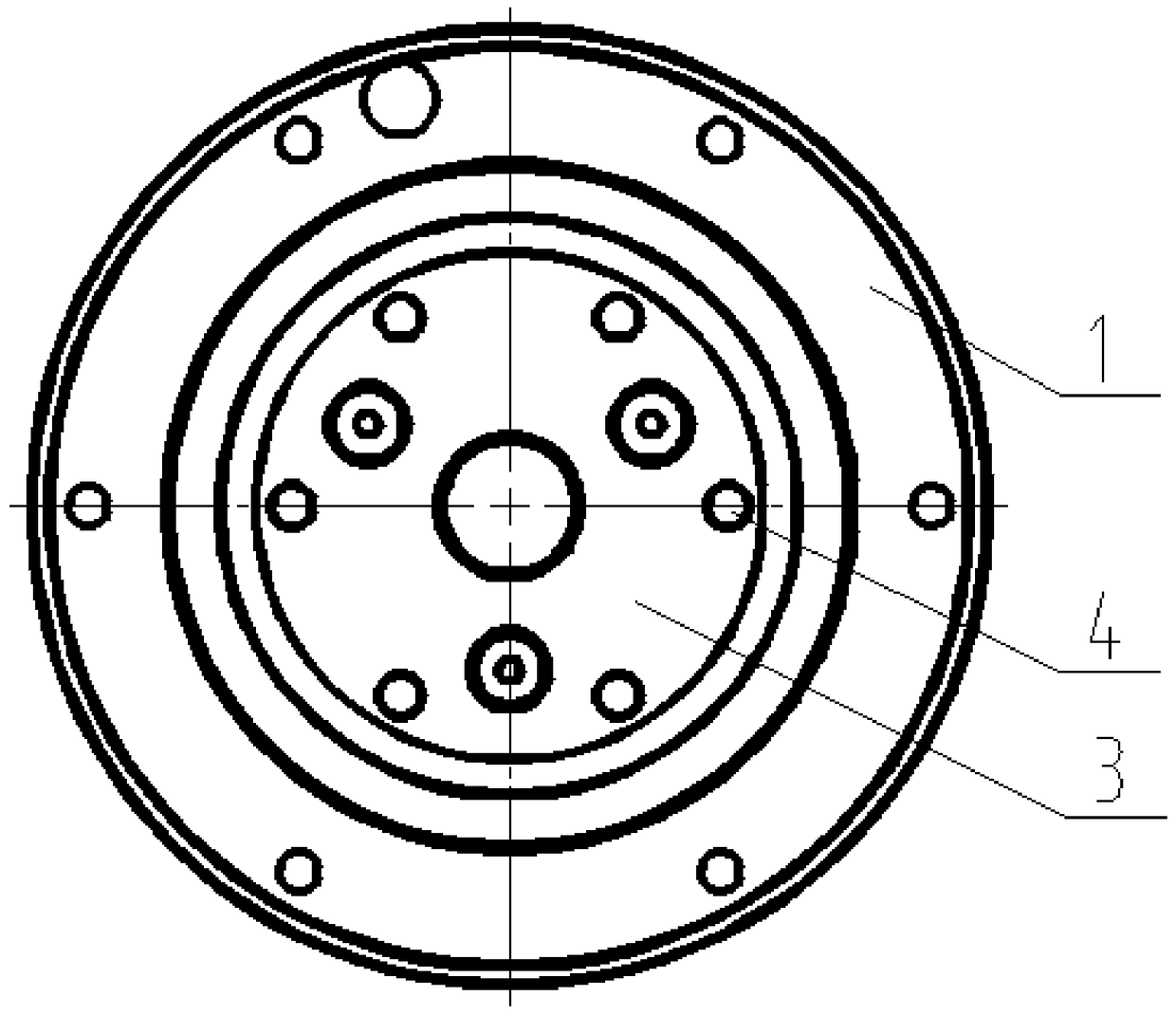

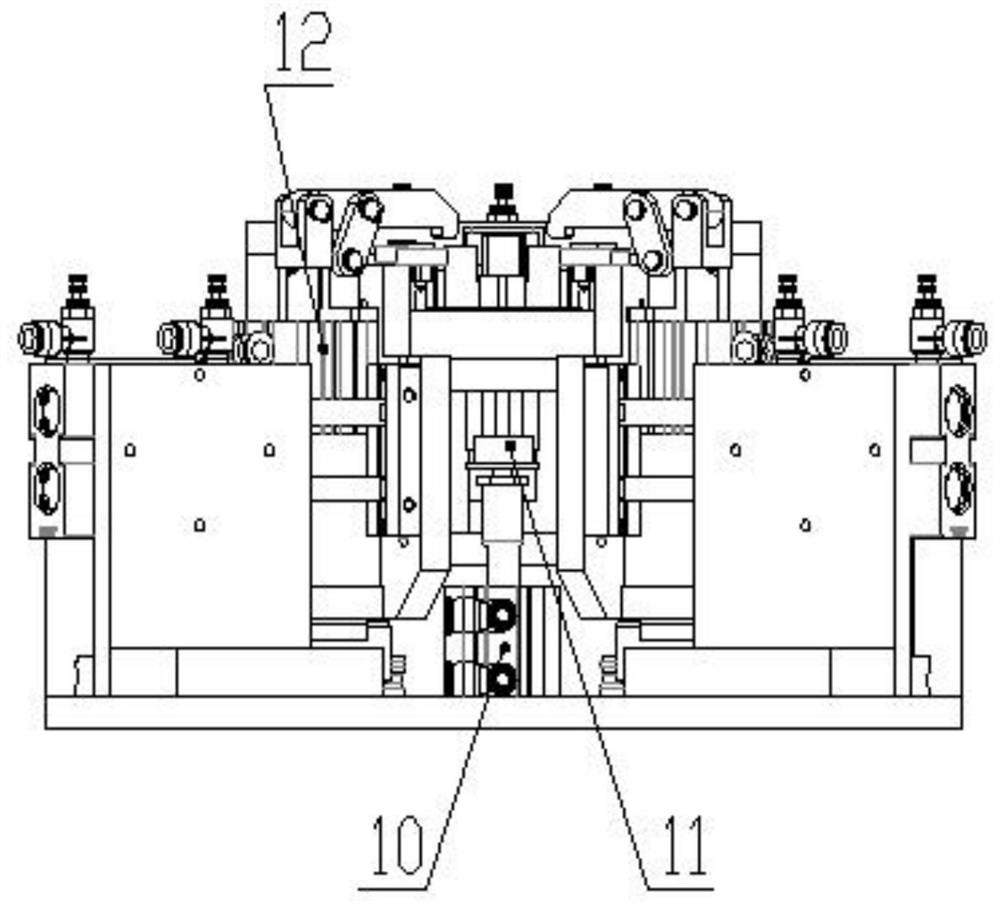

Welding clamp of water pump impeller

ActiveCN106312338AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlImpeller

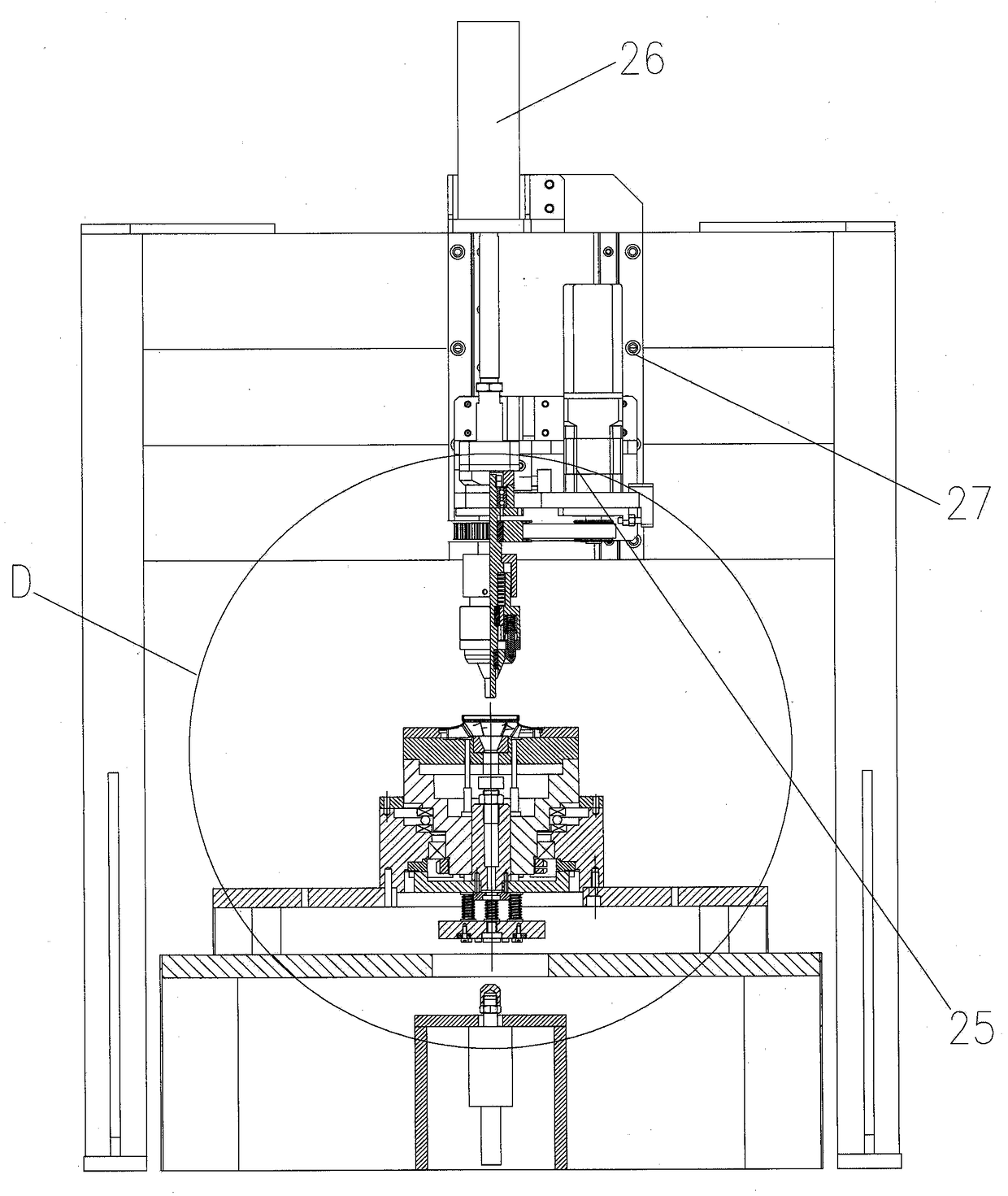

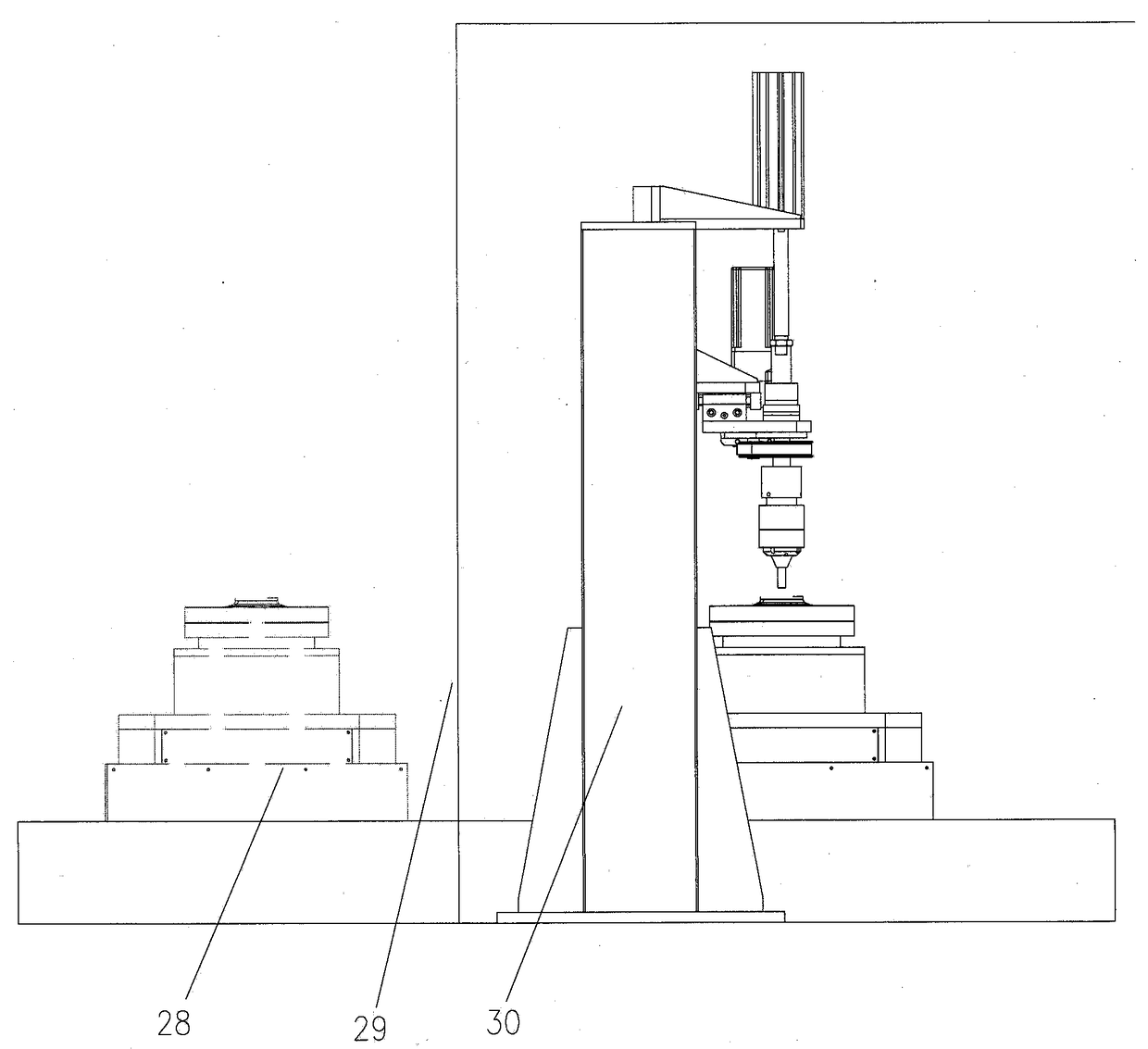

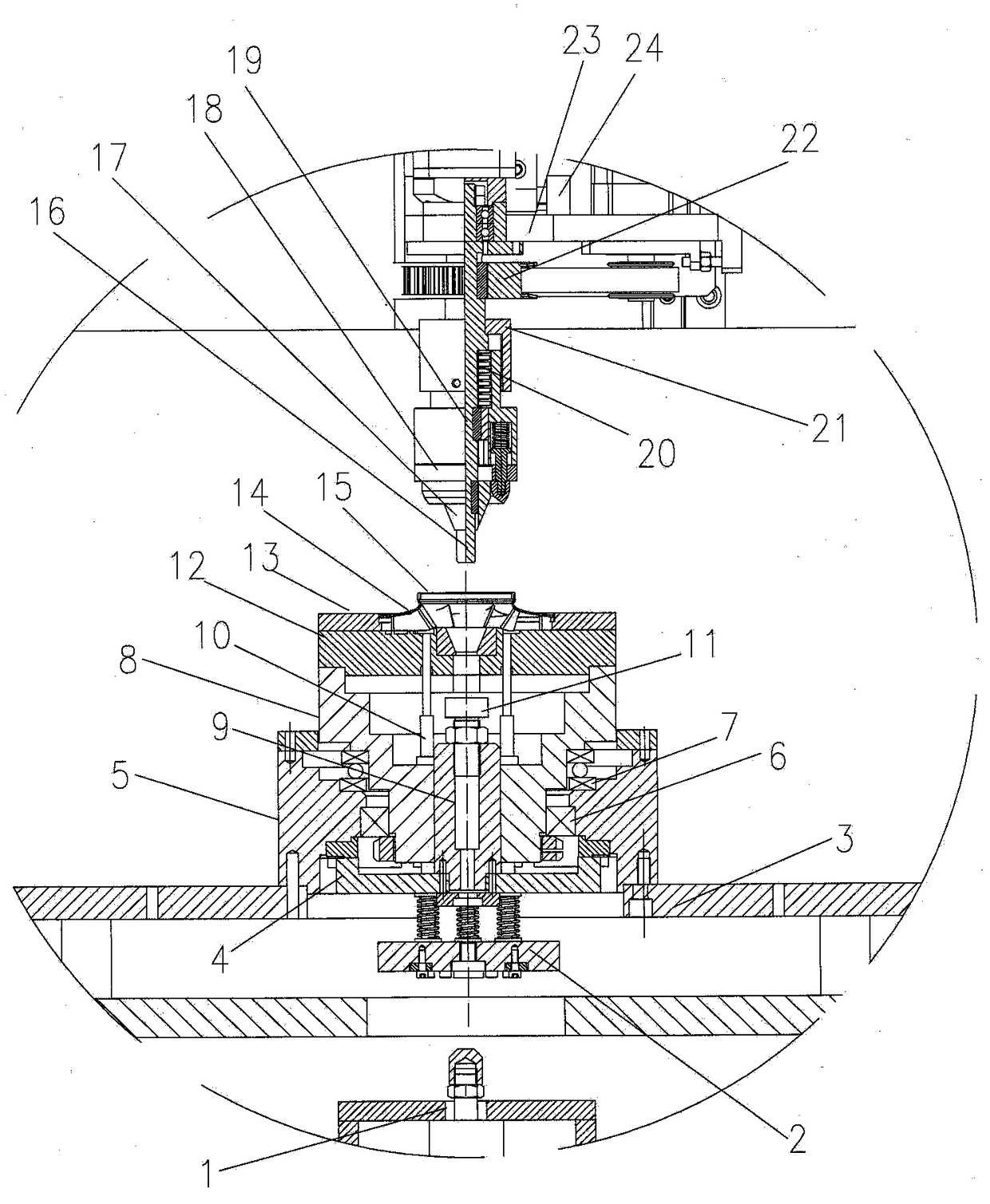

The invention relates to a welding clamp of a water pump impeller. The welding clamp comprises a rotating base, a mold seat, a pressing and rotating device, a friction transmission pair, a portal frame, a discharging device and a one-dimensional numerical control workbench. The mold seat is mounted on the rotating base and is coaxial with the rotating base, and the rotating base is mounted on the one-dimensional numerical control workbench. The pressing and rotating device is mounted on the portal frame. One end of the friction transmission pair is mounted on the pressing and rotating device, and the other end of the friction transmission pair is mounted on the mold seat. The discharging device is mounted on the lower portion of the rotating base. The portal frame is mounted above the rotating base in a stretching-over manner. It can be guaranteed that a rotating shaft of the pressing and rotating device and the rotating base are coaxial by adjusting the portal frame and the pressing and rotating device. Compared with a traditional welding device, the welding clamp is simple and fast in clamping and accurate in locating; through combination with the modern laser welding process, fast welding can be achieved; the welding quality is reliable; the zero rejection rate is achieved; the production efficiency is high; and the labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

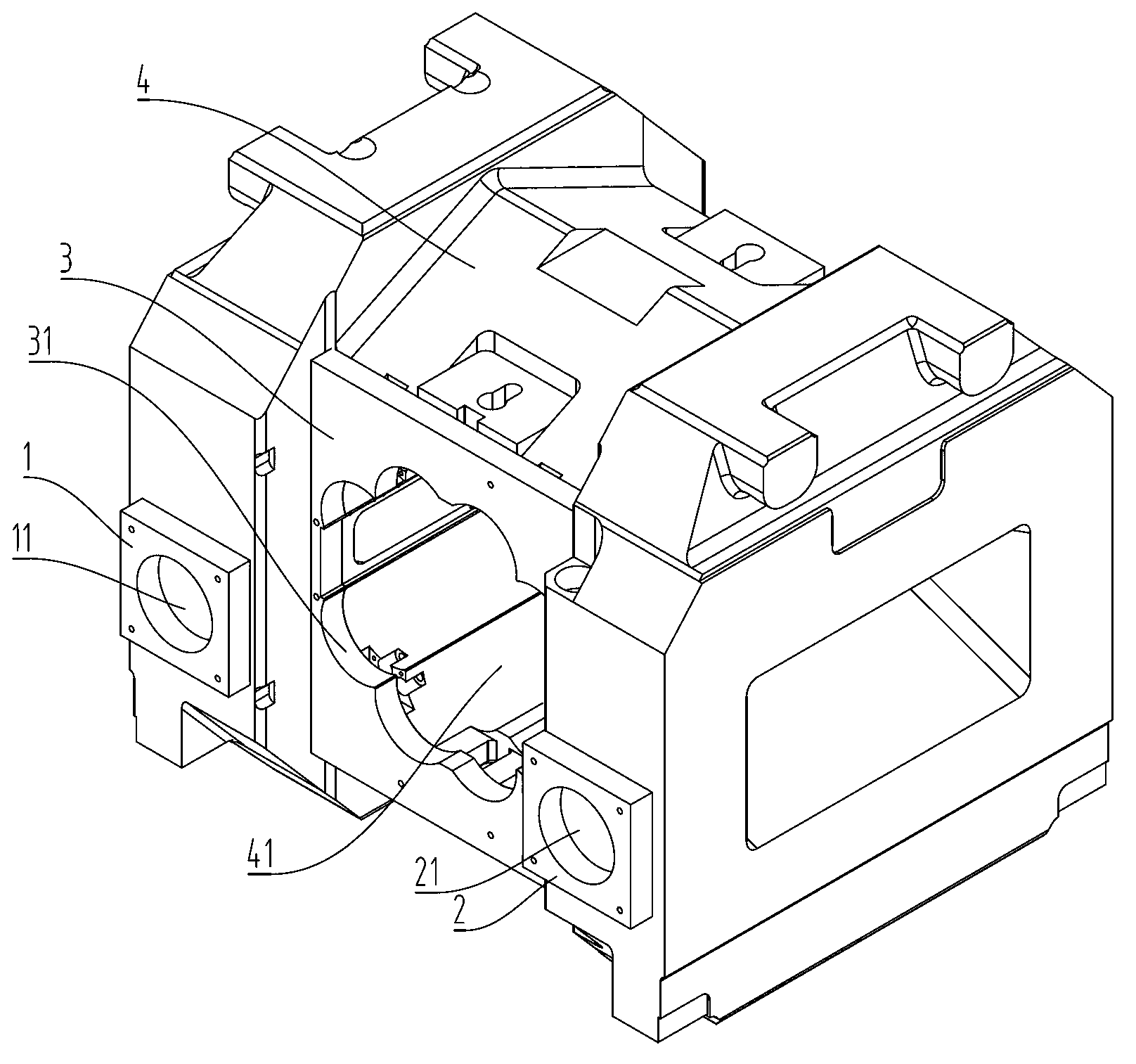

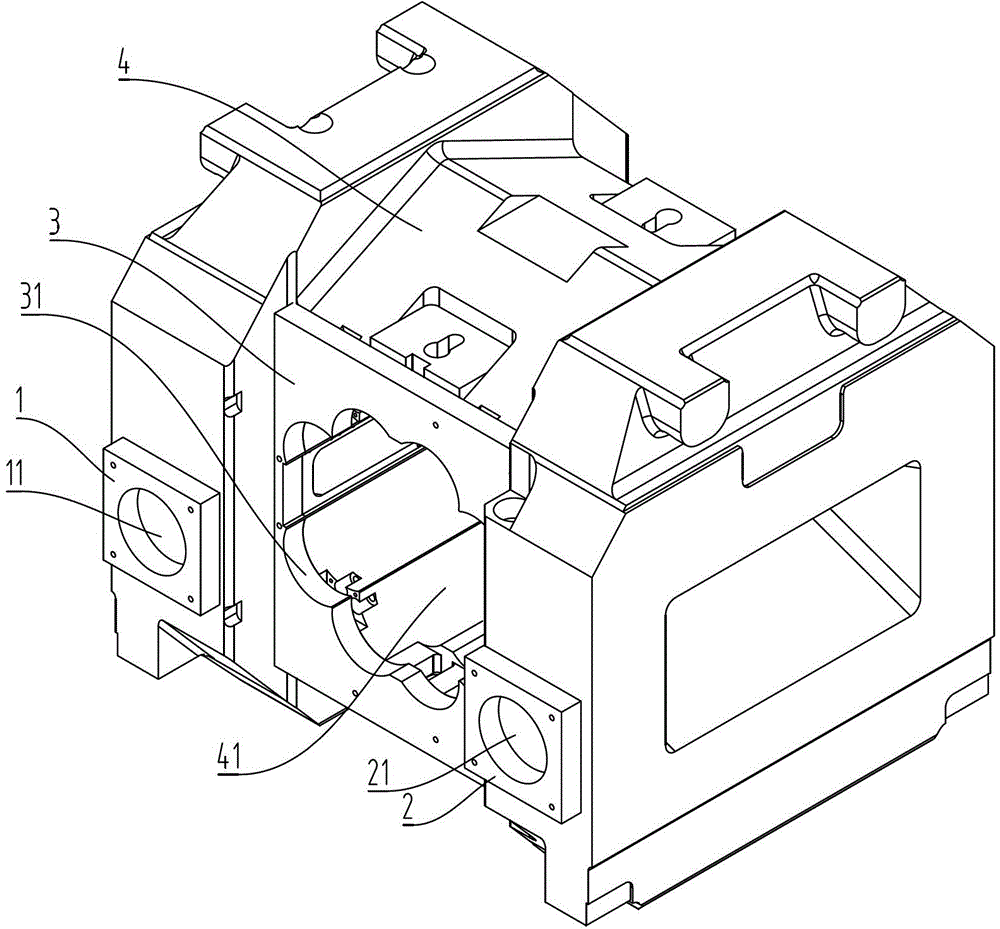

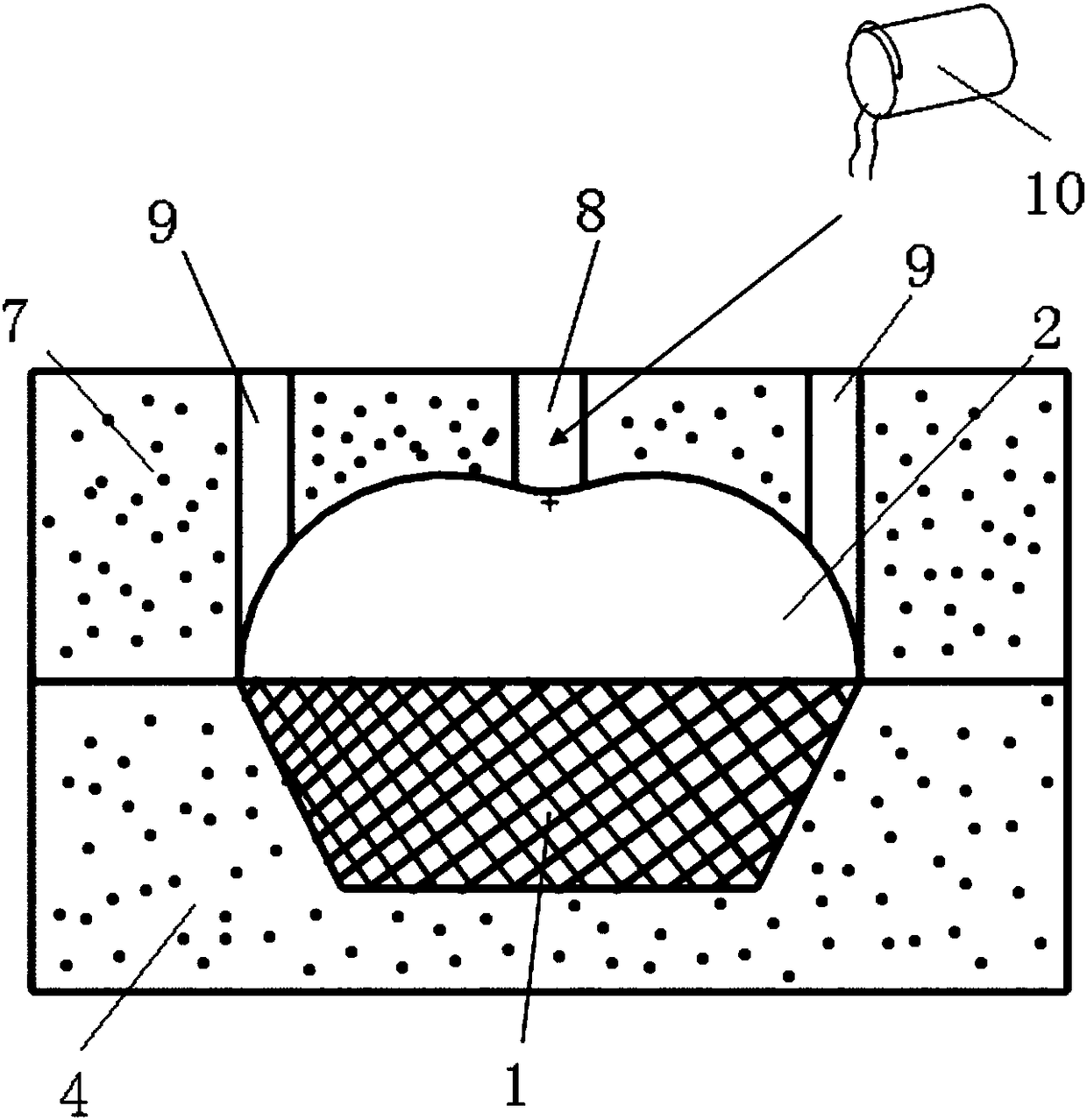

Processing method of mill housing

The invention discloses a processing method of a milling housing. A first plum blossom hole is formed in the housing and formed through cutting machining and abrasive machining on a housing substrate. The processing method is characterized in that during the cutting, the empirical formula of a cutting speed is as follows: V=3.14*D*n*eta<2> / 1000, wherein V represents the cutting speed with a unit of m / min; n represents the revolving speed of a machine tool spindle with a unit of rpm; D represents a cutting radius ranging from 260mm to 360mm; eta<2> is a coefficient ranging from 0.05 to 0.08; the smaller the difference between the size of the plum blossom hole and a design value is, the larger the value of the plum blossom hole is; and otherwise, the value of the plum blossom hole is smaller. By means of the processing method of the mill housing, the mill housing which meets the accuracy requirement can be processed. According to the processing method, the dimensional tolerance of diagonal plum blossom holes of the mill housing are smaller than or equal to 0.01mm, the total tolerance is smaller than or equal to 0.02mm, and the straightness of each hole is smaller than or equal to 0.01mm. With the adoption of the method for processing the housing, under the condition that smooth and efficient processing is guaranteed, the housing substrate cannot be scrapped, and the scrappage rate is zero under the condition that the processing efficiency is improved by over 20%.

Owner:上海山弈冶金技术有限公司

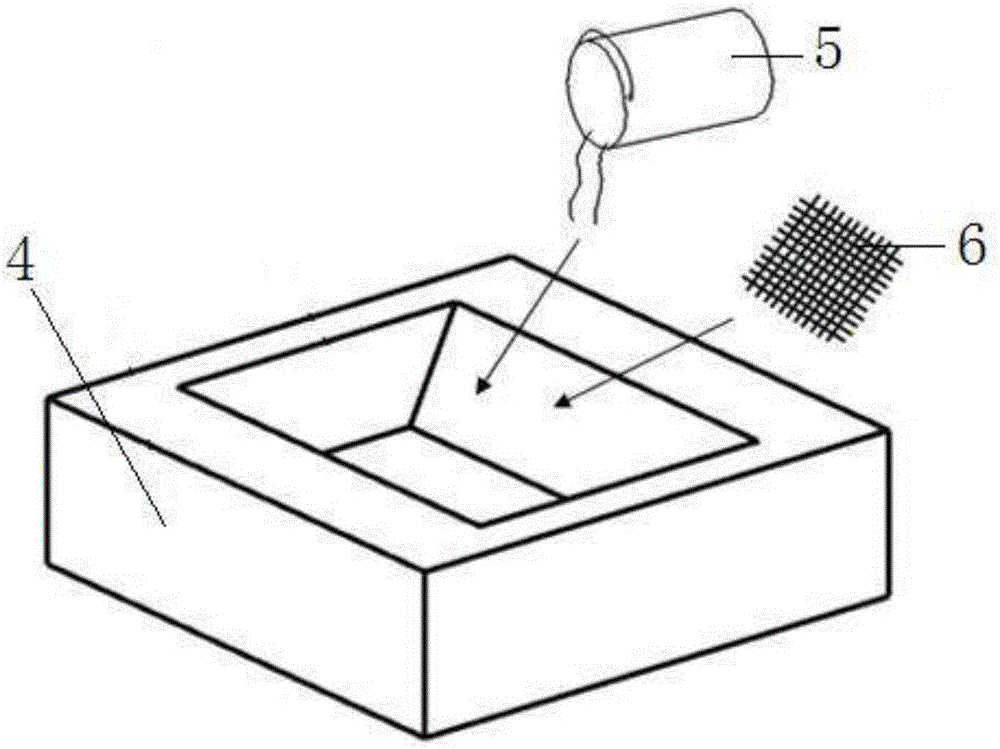

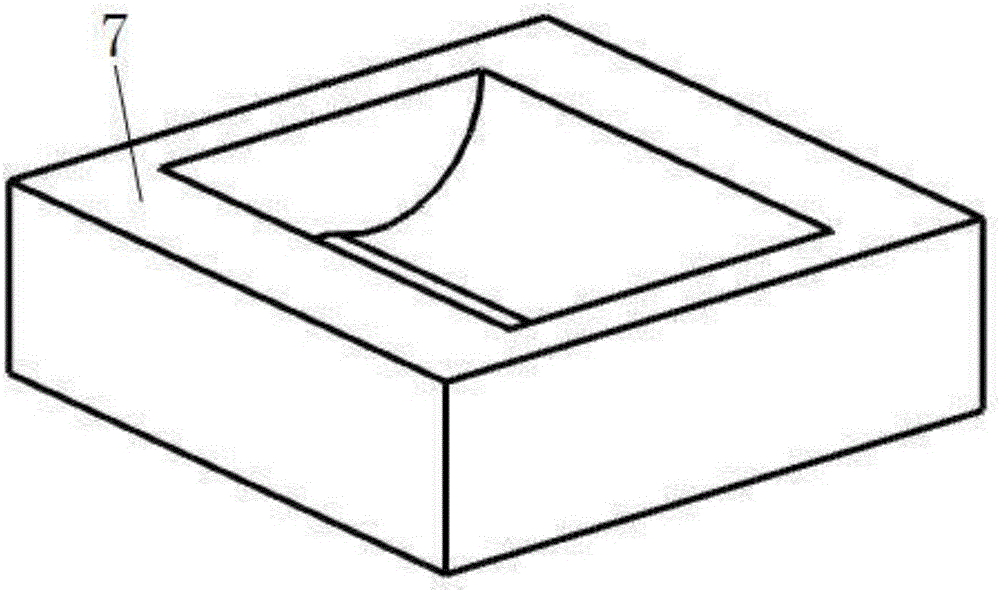

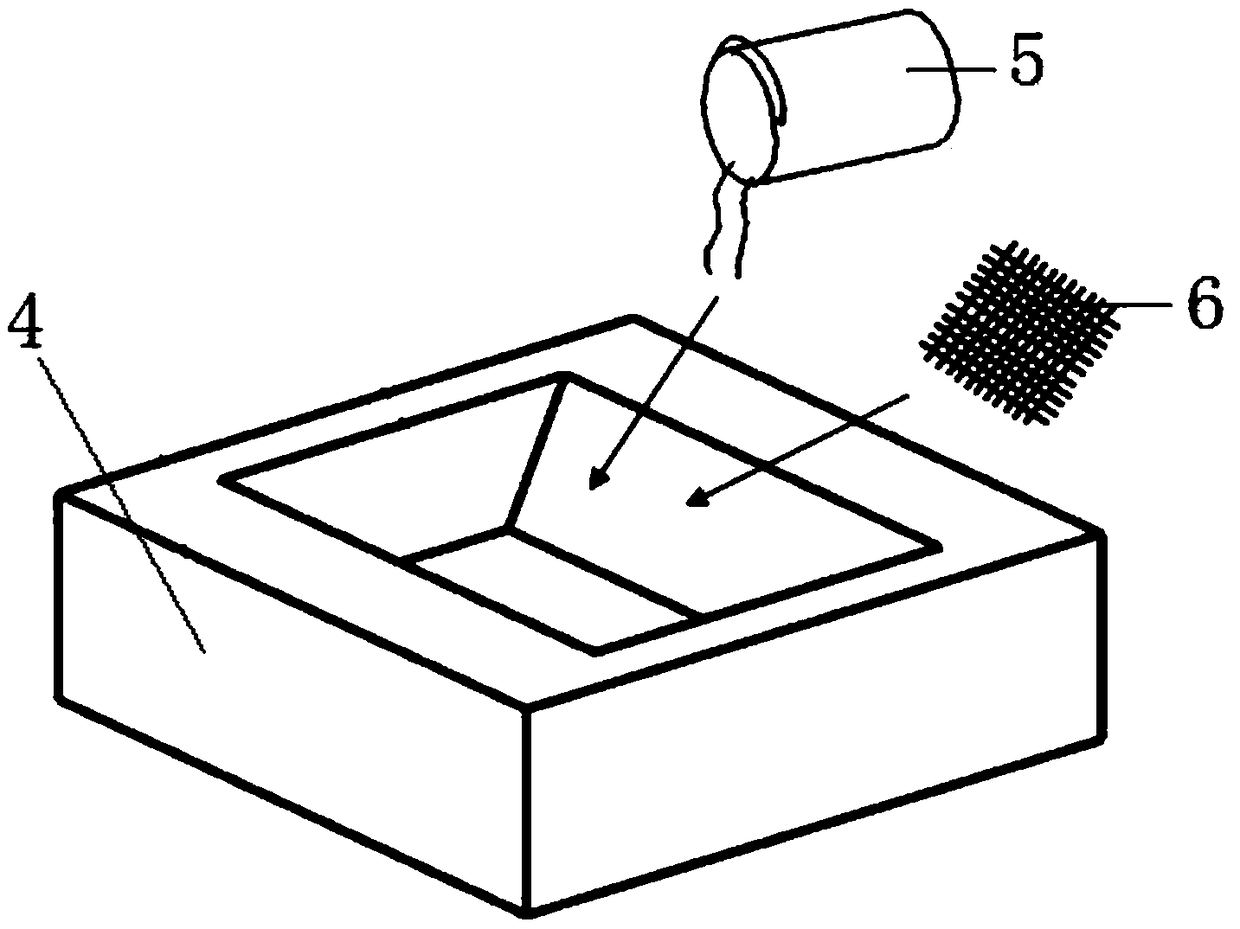

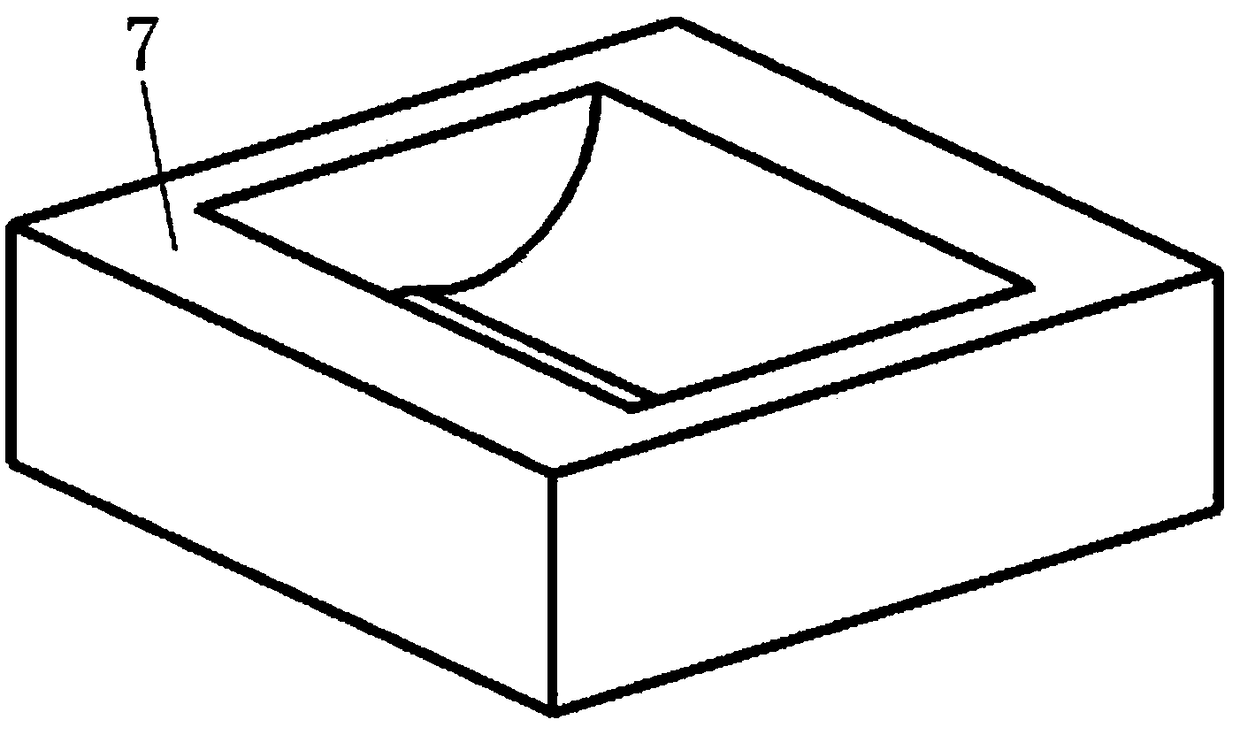

Manufacturing method for airplane part stretch-forming mold made of resin matrix composite

ActiveCN105945159AWith self-lubricating functionUniform surface hardnessShaping toolsNumerical controlResin matrix

The invention discloses a manufacturing method for an airplane part stretch-forming mold made of a resin matrix composite and mainly aims to solve the problems that existing molds are large in manufacturing difficulty, hard to store and large in weight and cannot be repaired. The provided manufacturing method for the airplane part stretch-forming mold made of the resin matrix composite comprises the steps that a matrix and a surface are manufactured with the resin matrix composite; and then the airplane part stretch-forming mold is machined and manufactured through a numerical control machine tool. By means of the manufacturing method, the mold using rate is increased, especially, the part productivity is improved, the mold manufacturing cost is reduced, and the mold manufacturing period is shortened.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

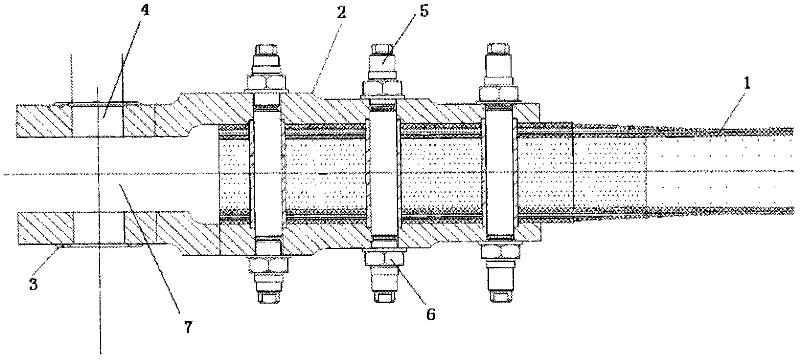

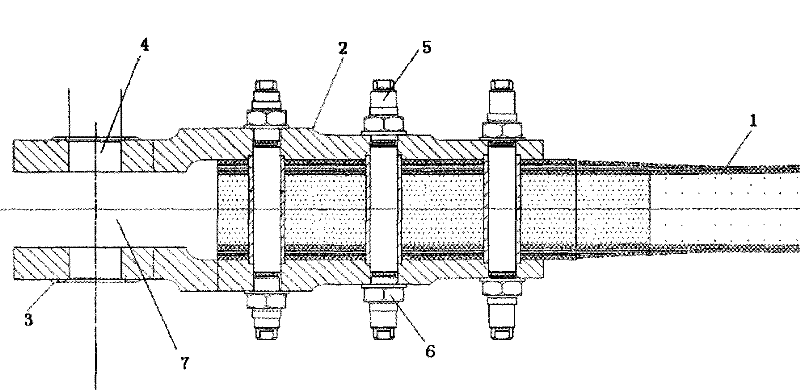

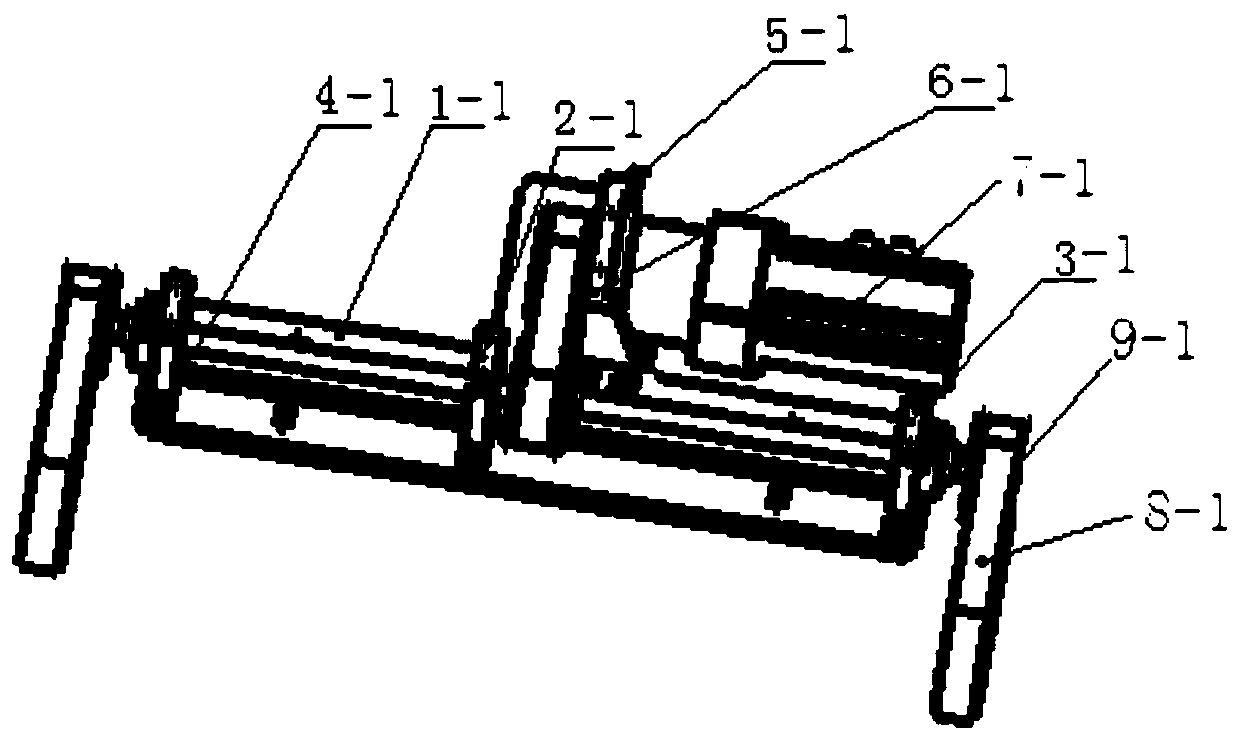

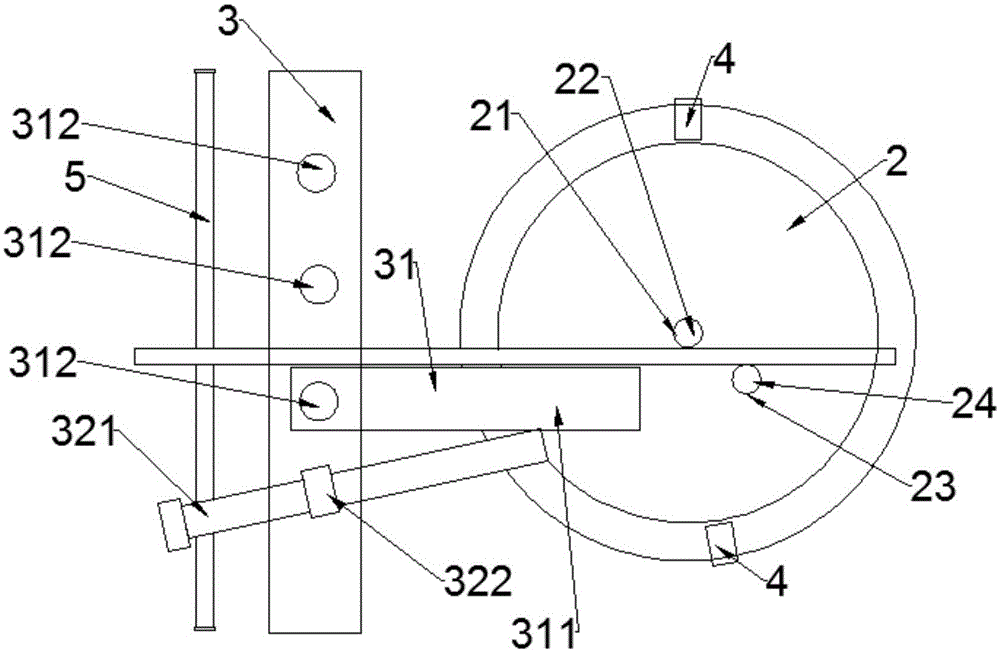

Circular oil distributing pipe welding clamping device

InactiveCN108422113AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe welding

The invention relates to a circular oil distributing pipe welding clamping device including a self-made synchronous belt rotating assembly, an external chuck assembly and a mounting bracket assembly.The external chuck assembly is arranged on the self-made synchronous belt rotating assembly. The self-made synchronous belt rotating assembly is arranged on the mounting bracket assembly. The self-made synchronous belt rotating assembly, the external chuck assembly and the mounting bracket assembly are arranged on a device working table. A photoelectric sensor is arranged on the self-made synchronous belt rotating assembly. As an initiator of a signal, the photoelectric sensor ensures the consistency and the stability of welding in welding process of a workpiece. The circular oil distributingpipe welding clamping device of the invention has accurate positioning, reliable welding and high efficiency.

Owner:WUHAN CHUTIAN IND LASER EQUIP

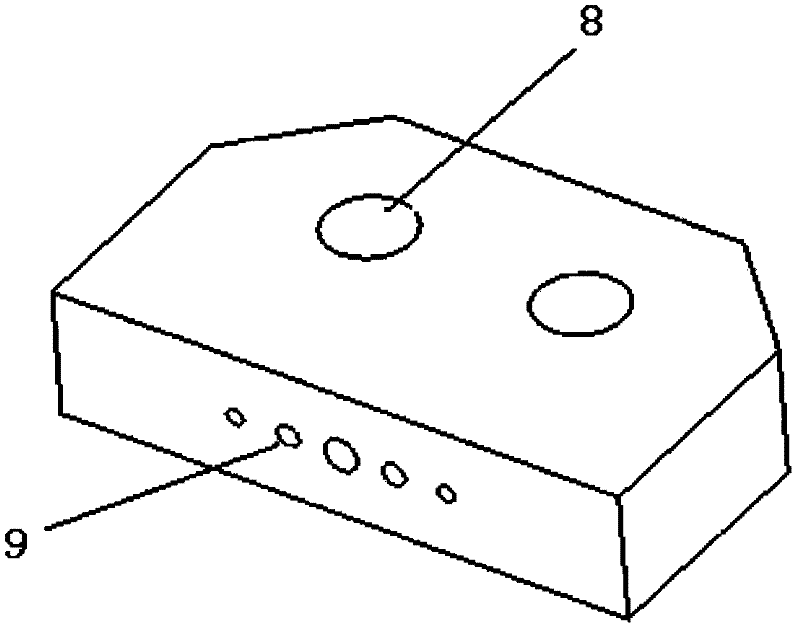

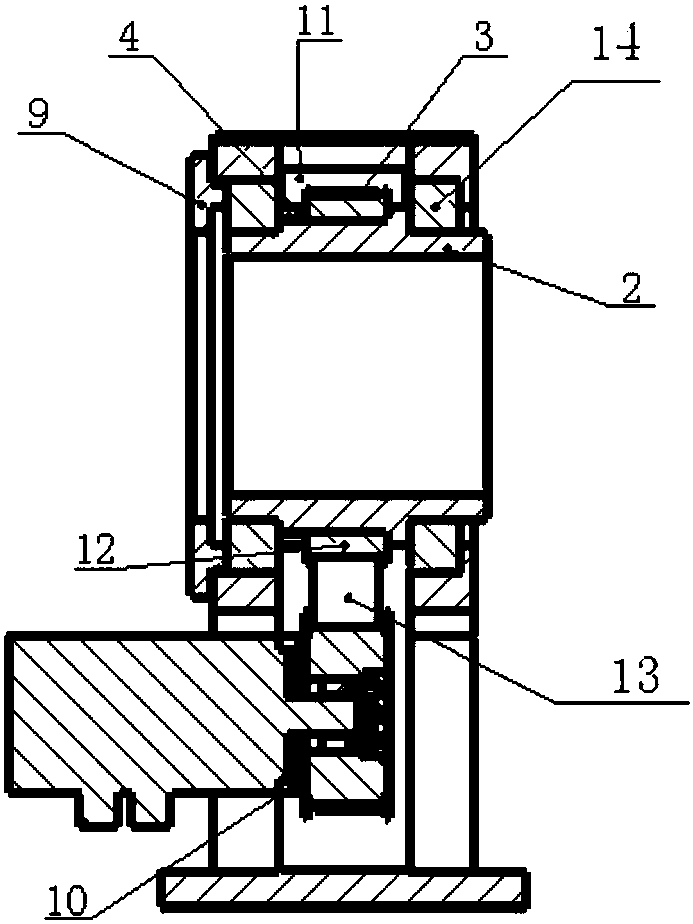

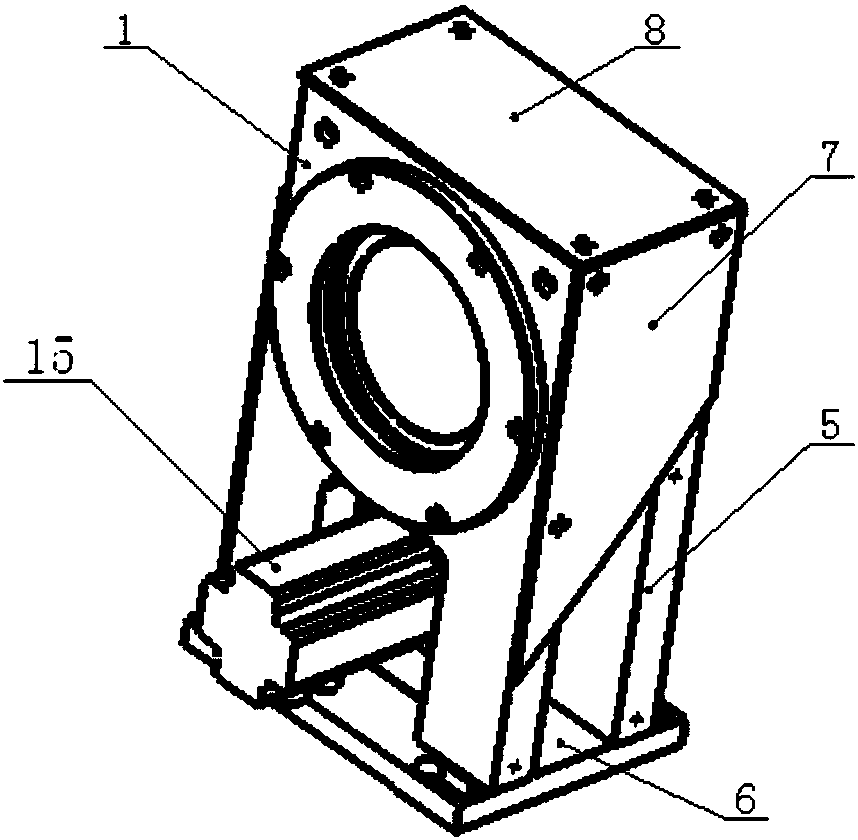

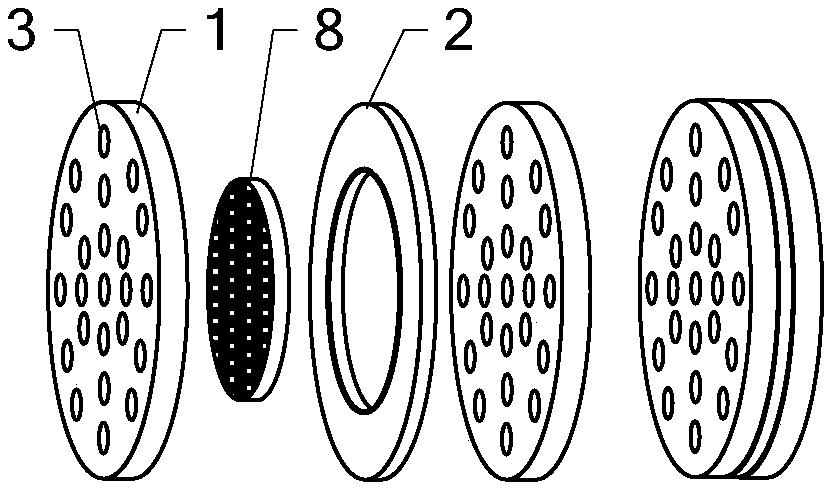

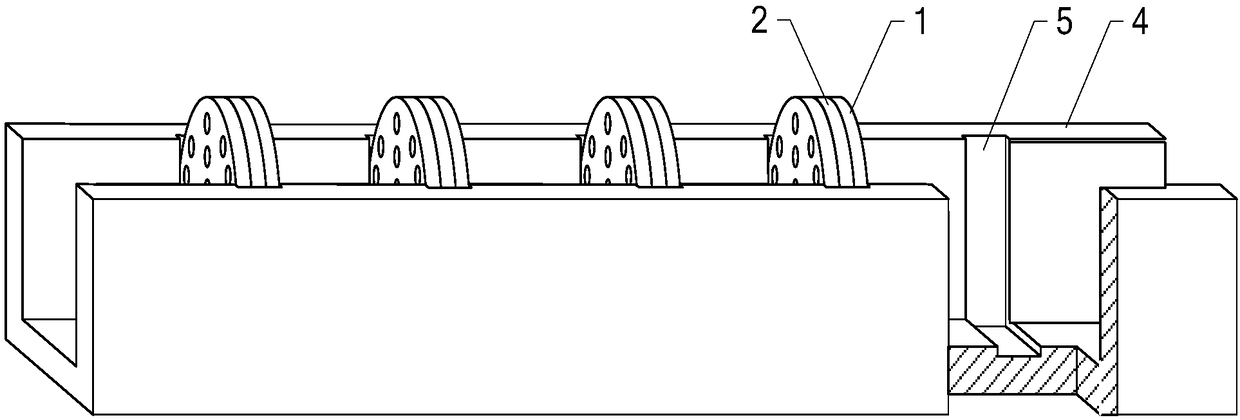

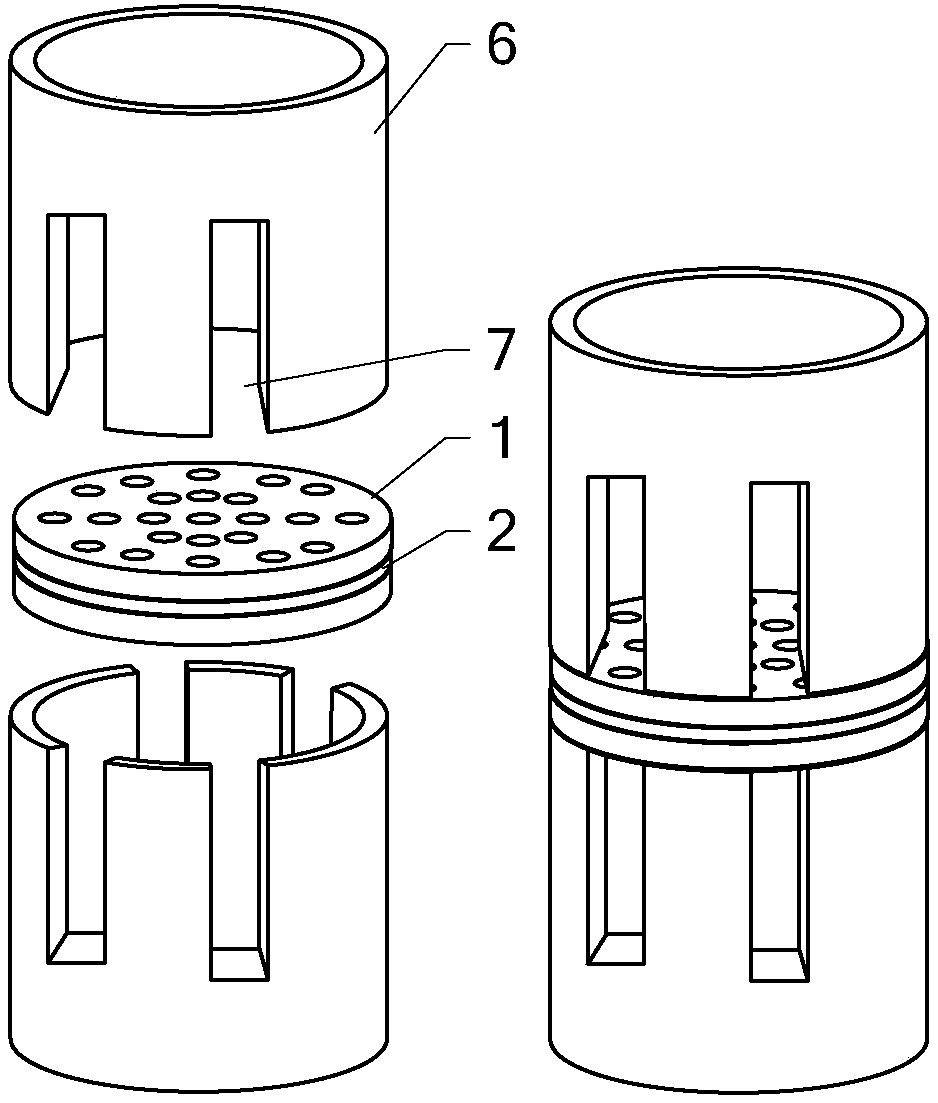

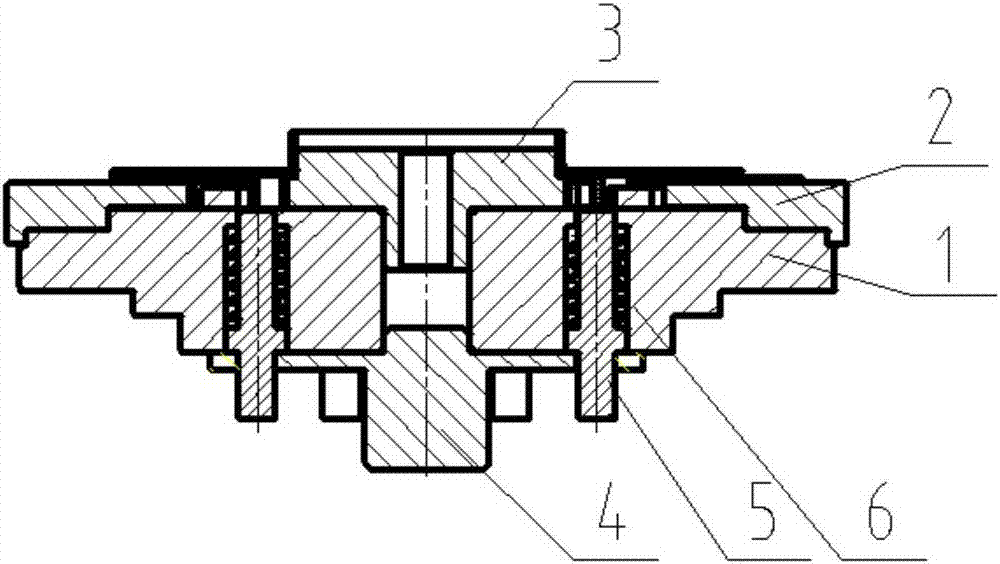

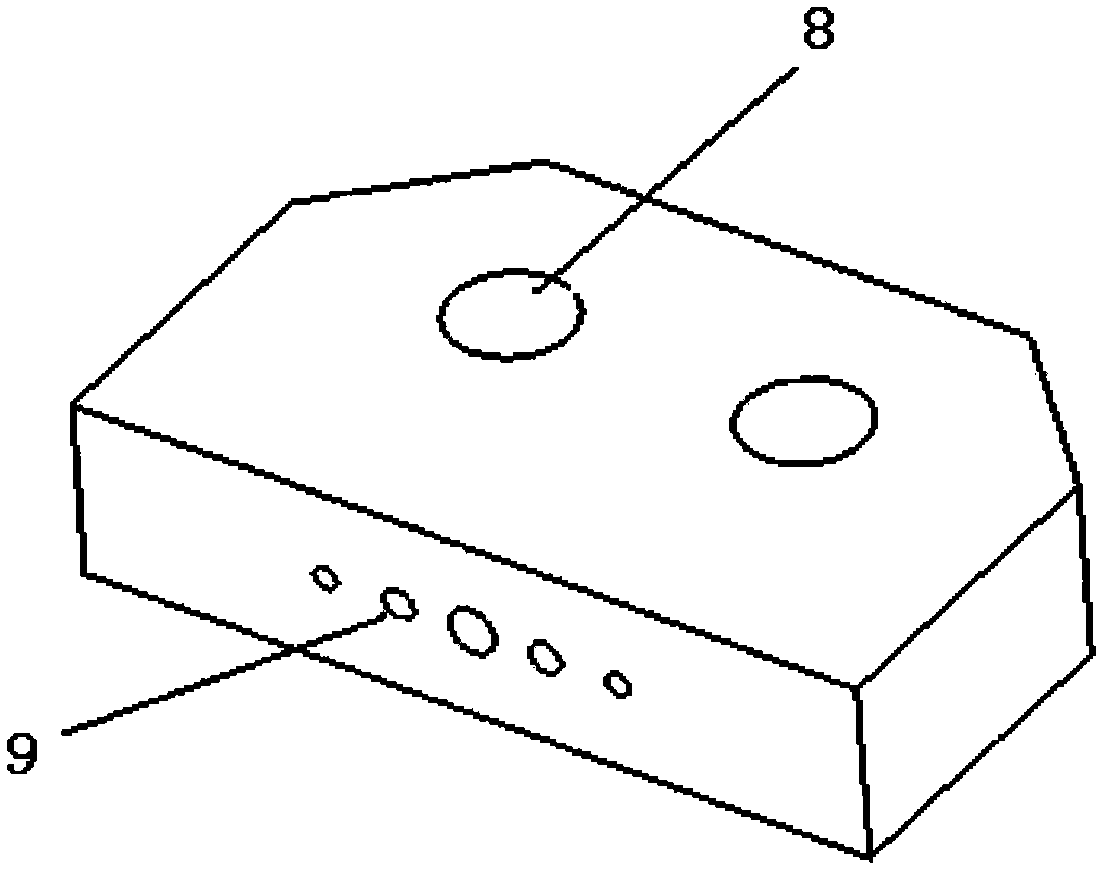

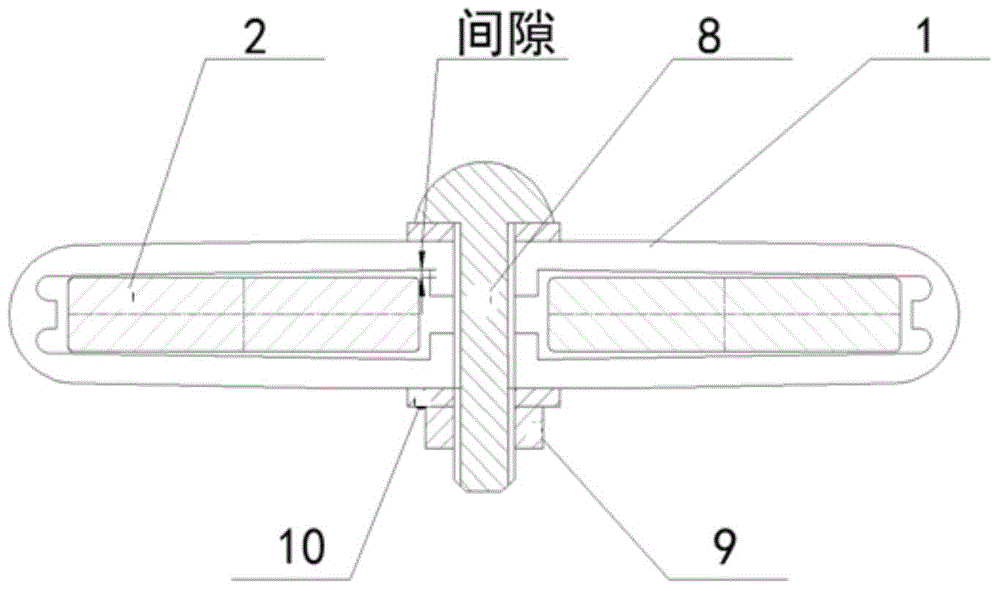

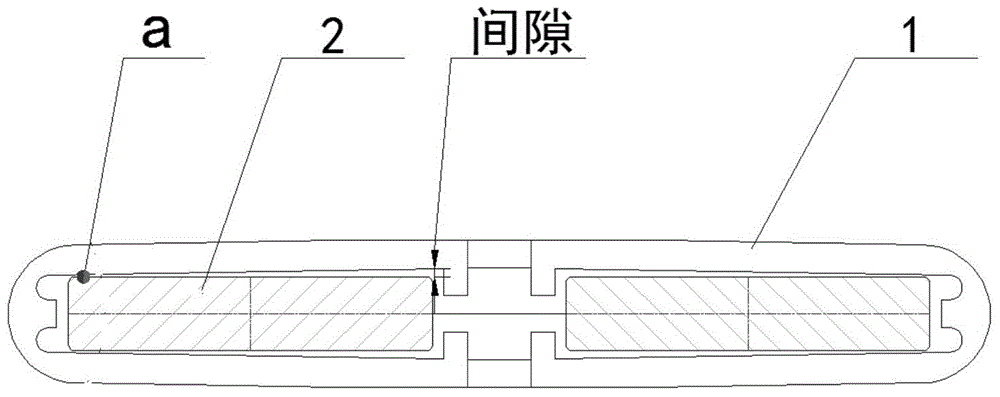

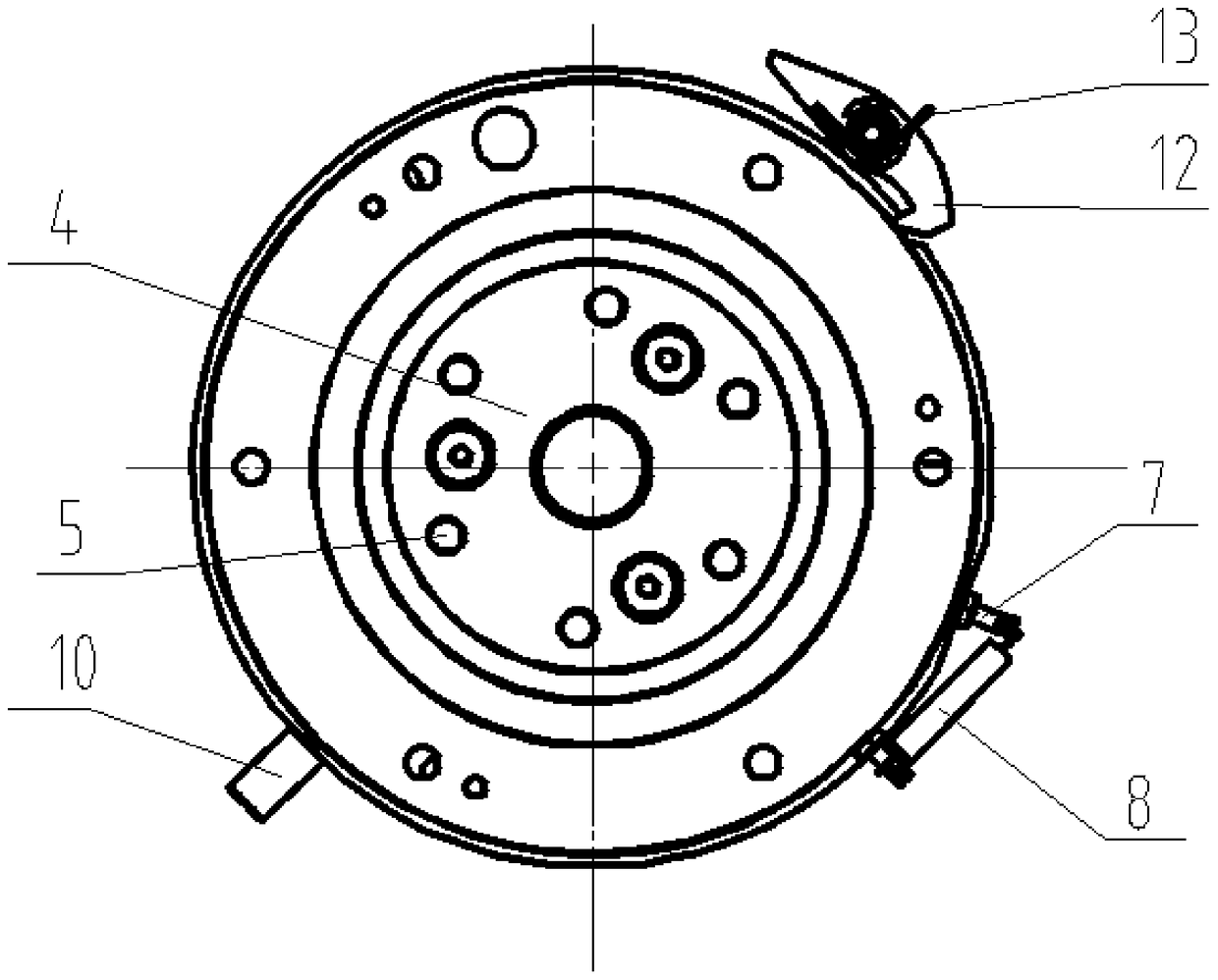

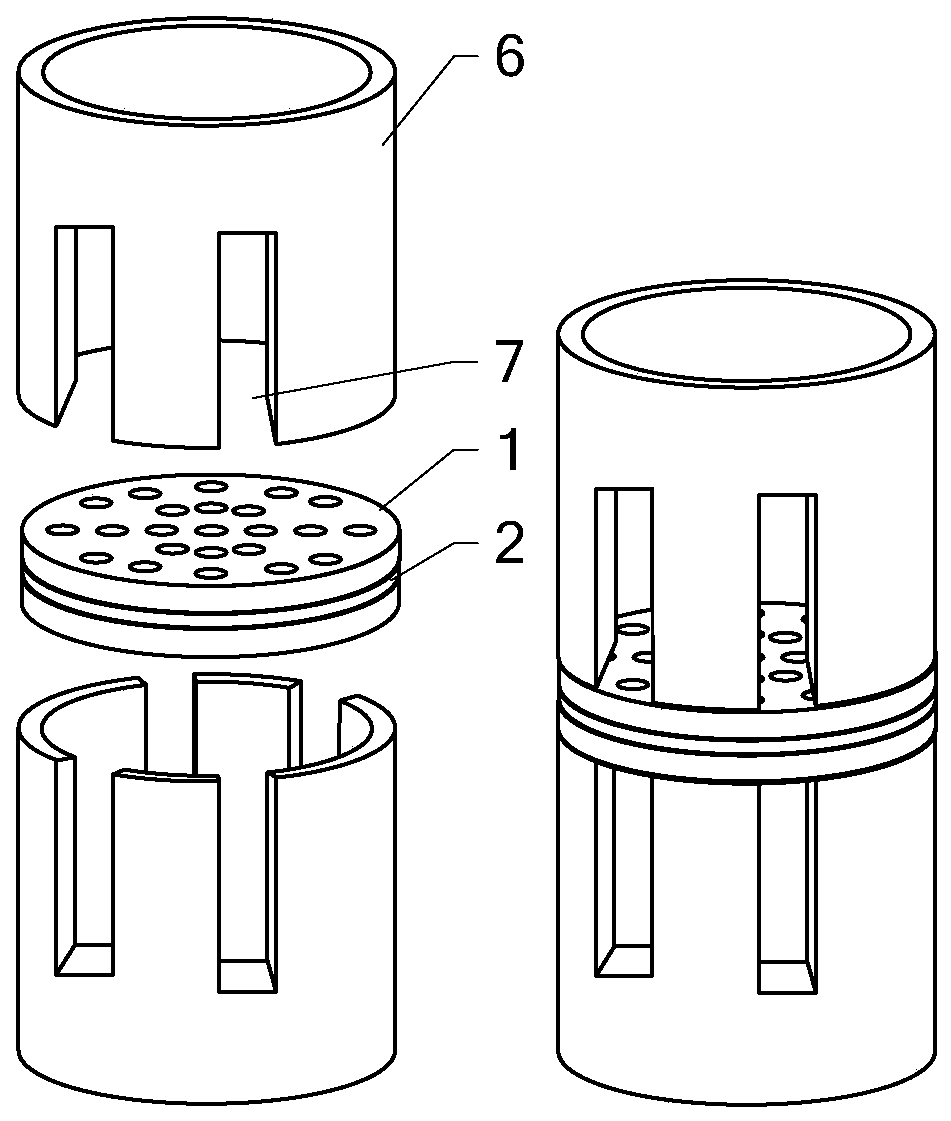

Si-microchannel plate base integral oxidation anti-deformation constraint device

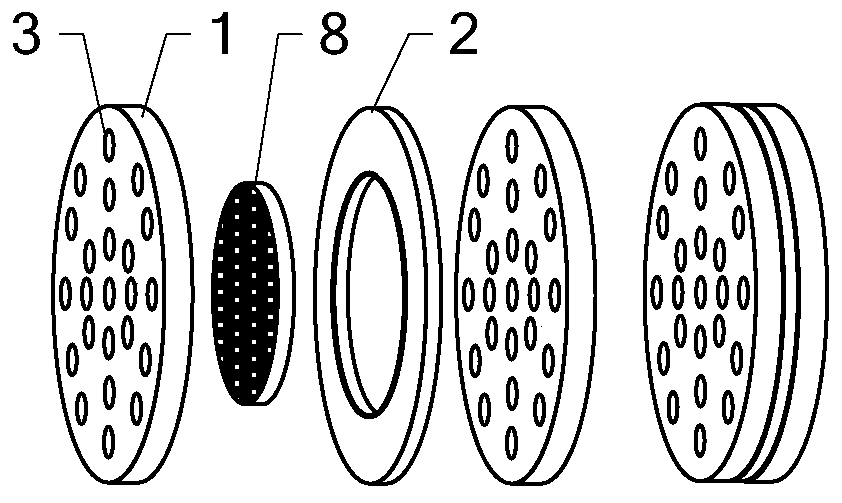

ActiveCN108281338AZero scrap rateNo sintering phenomenonDecorative surface effectsPhoto-emissive cathodes manufactureCircular discTotal thickness

The invention discloses an Si-microchannel plate base integral oxidation anti-deformation constraint device and belongs to the technical field of photoelectron devices, aiming to overcome the defect of deformation of the Si-microchannel plate base due to oxidation. The anti-deformation constraint device is characterized in that a left guard plate and a right guard plate clamp one retainer ring, the guard plates and the retainer ring are made of sapphire crystals and shaped as circular discs having the same outside diameter, the middles of the guard plates are provided with pores uniformly, theguard plates are 2-3mm in thickness, and the retainer ring is 25-30mm in inside diameter and 350-400 microns in thickness; a plurality of clamp slots are uniformly distributed transversely in a groove-shaped horizontal clamp mount, the width of the clamp slots is greater than the total thickness of the two guard plates and the retainer ring by 20-30 microns; the rims of vertical hold-down barrelsare provided with elongated pores; the horizontal clamp mount and the vertical hold-down barrel are both made of quartz glass; the two guard plates and the retainer ring are positioned in one clamp slot or held down by the upper and lower vertical hold-down barrels, and the rims of the two vertical hold-down barrels are in opposite arrangement. The tolerance of flatness of the Si-microchannel plate is smaller than 10 microns after integral oxidation.

Owner:CHANGCHUN UNIV OF SCI & TECH

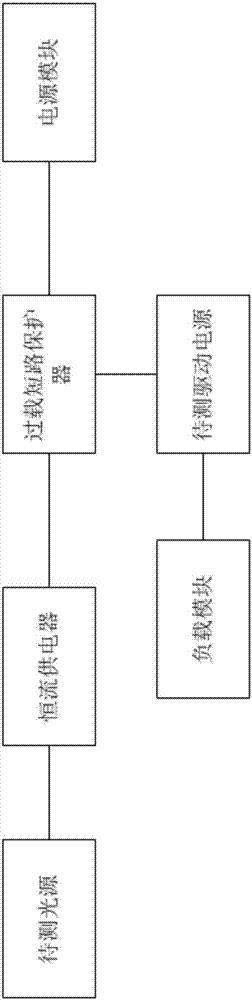

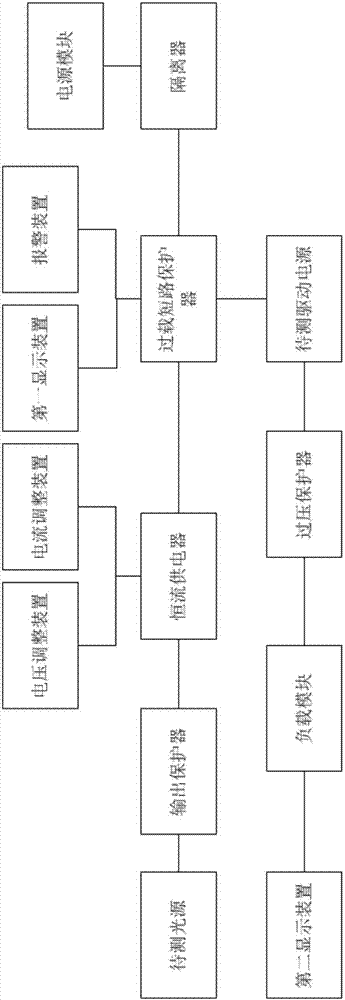

LED multifunctional tester

PendingCN107064825ASimple structureZero scrap rateOverload protection arrangementsPower supply testingCurrent loadControl engineering

The invention relates to the field of LED testing, and especially relates to an LED multifunctional tester. The LED multifunctional tester comprises an overload short-circuit protector, a constant-current power supplier, a load module, a power supply module, a to-be-measured light source and a to-be-measured drive power supply; the power supply module is electrically connected with an input end of the overload short-circuit protector, an input end of the constant-current power supplier is electrically connected with an output end of the overload short-circuit protector, the to-be-measured light source is accessed to an output end of the constant-current power supplier, and the to-be-measured drive power supply is accessed to a part between the output end of the overload short-circuit protector and the load module; and the constant-current power supplier adjusts a voltage and a current of an output end of the to-be-measured light source according to a rated parameter of the to-be-measured light source, and the load module adjusts an resistance value of the to-be-measured drive power supply according to a rated parameter of the to-be-measured drive power supply. The LED multifunctional tester has simple structure, can simultaneously measure the quality of an LED light source and the quality of an LED drive power supply, and also can guarantee the measured light source and the measured drive power supply to be not damaged during testing.

Owner:常东记

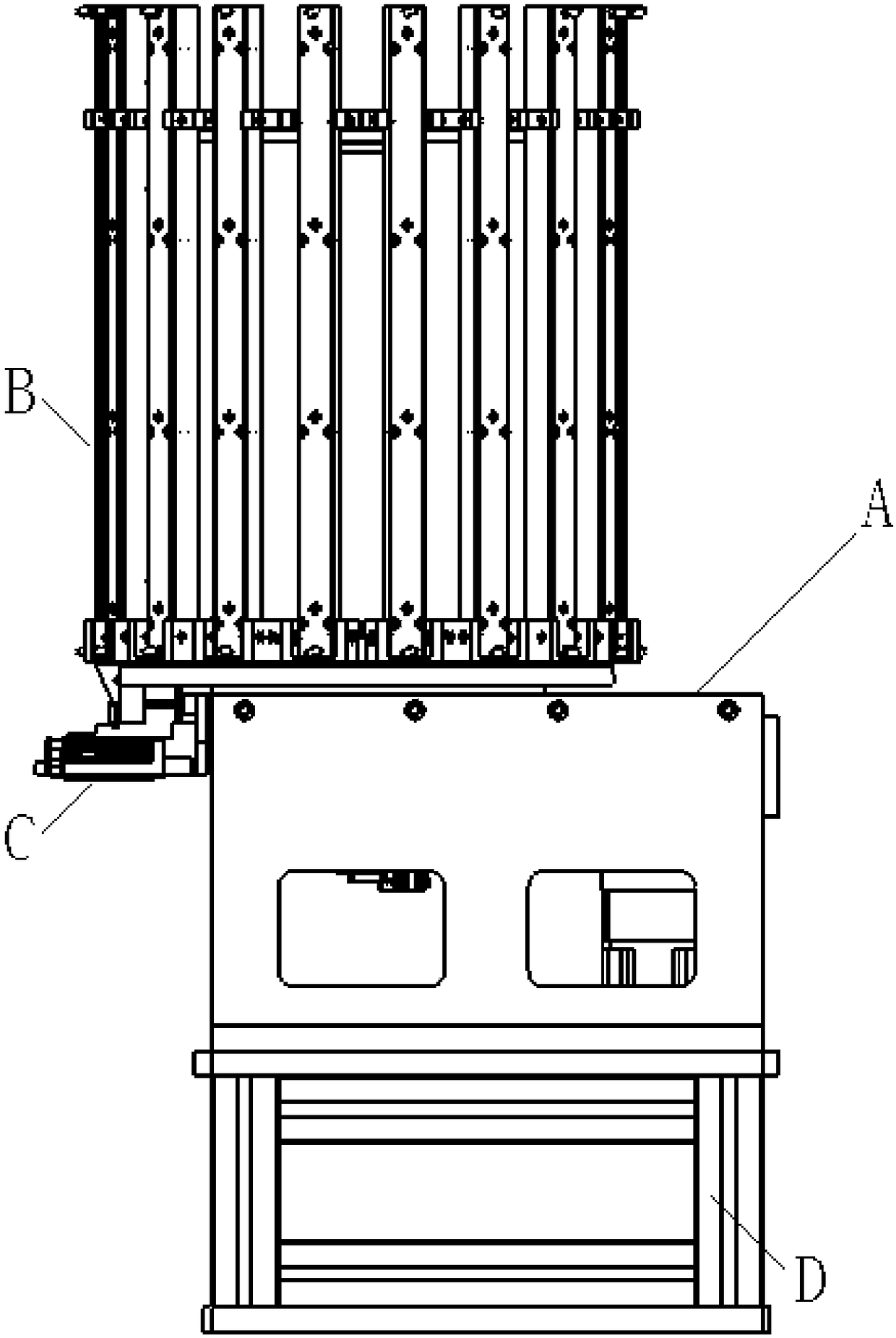

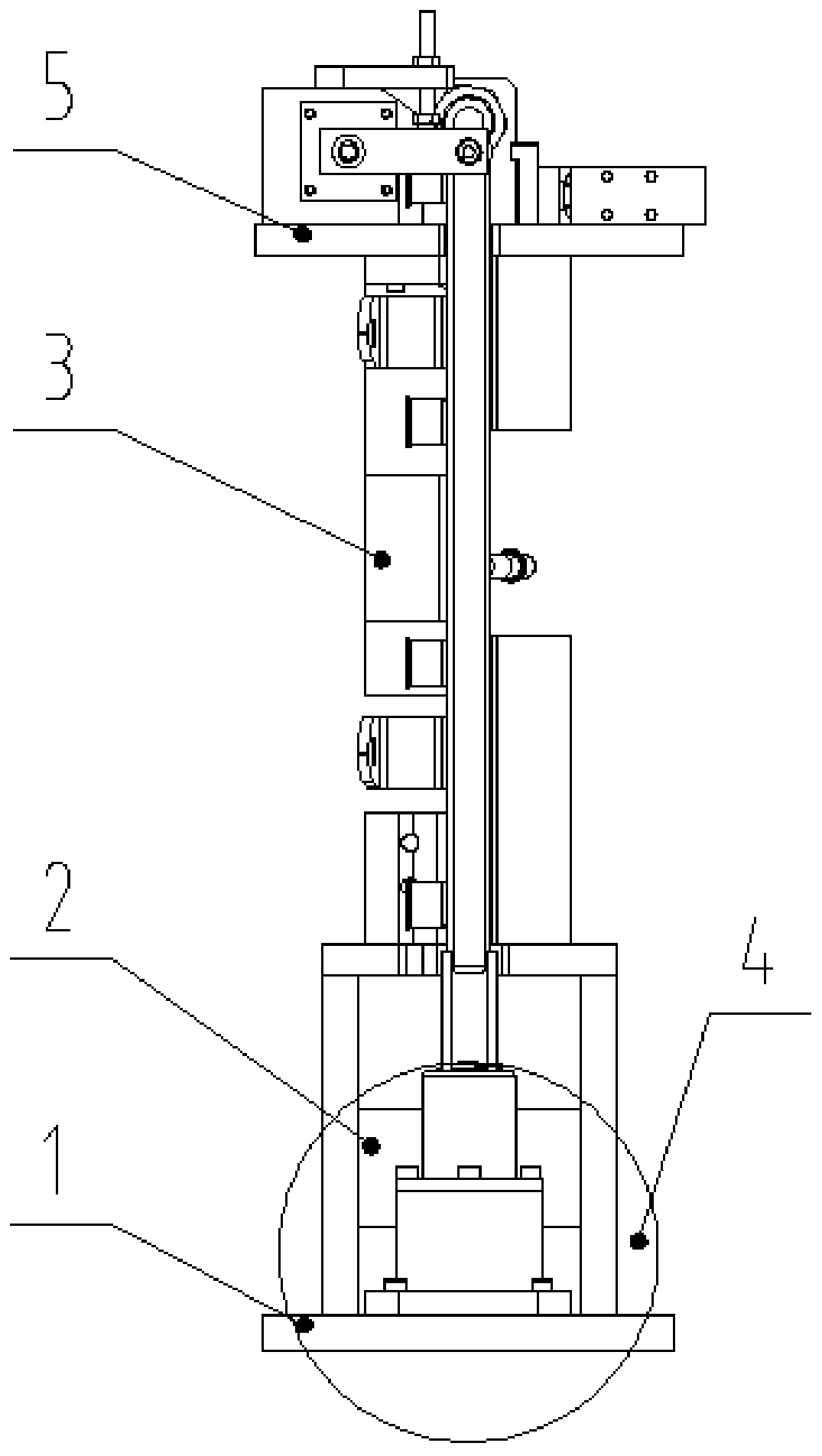

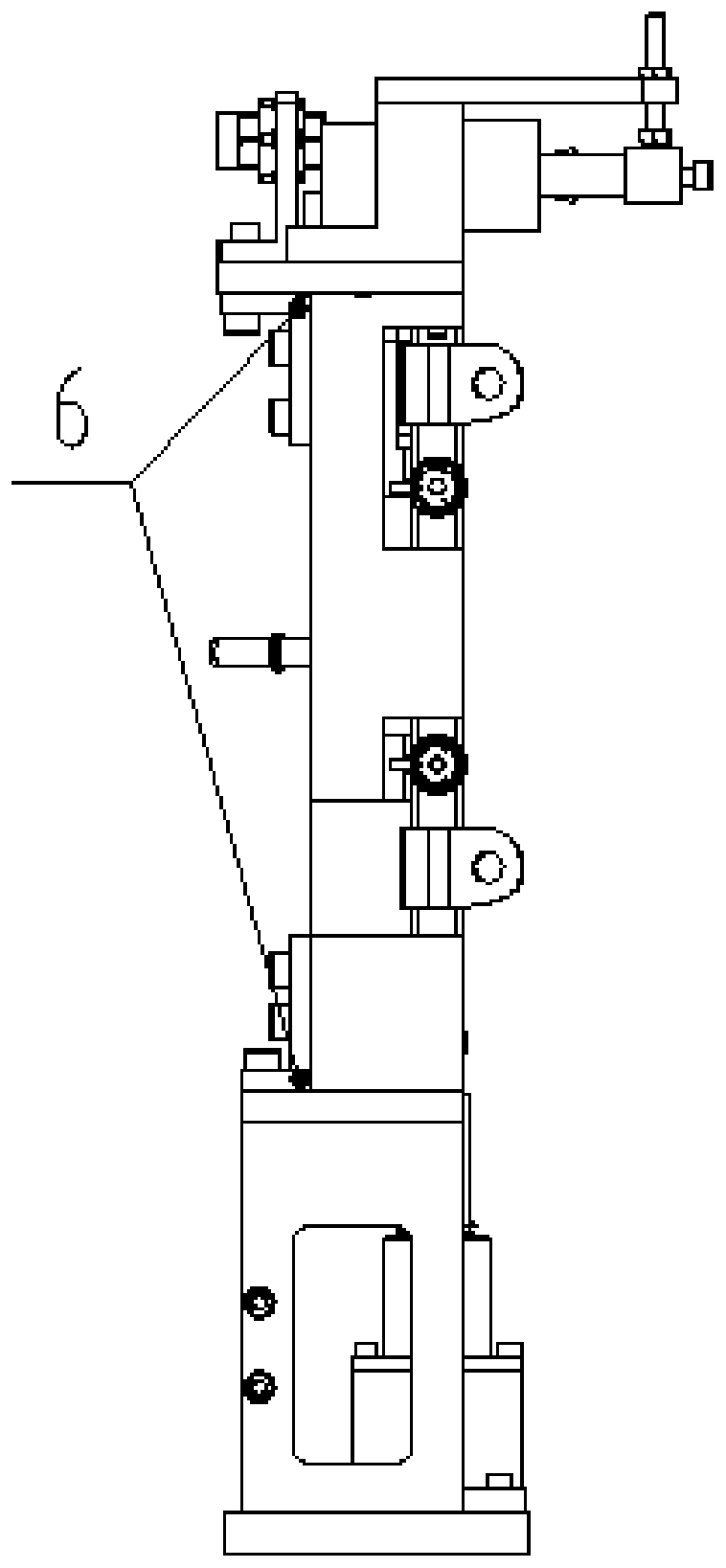

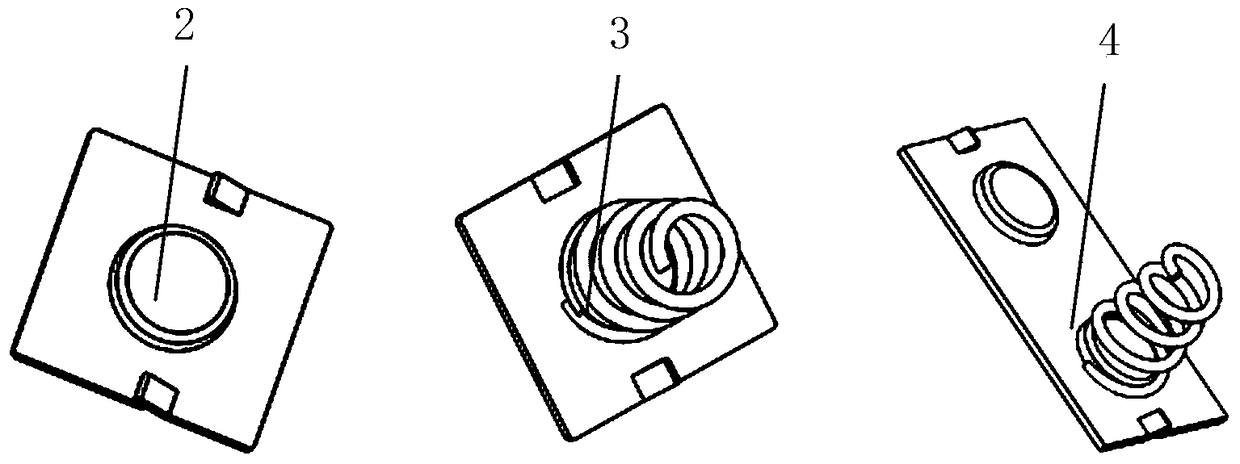

Ratchet wheel locking type impeller welding clamp with auxiliary discharging function and control method thereof

InactiveCN106862762AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesSurface finishImpeller

The invention relates to a ratchet wheel locking type impeller welding clamp with the auxiliary discharging function and a control method thereof. The clamp comprises a base, a center shaft, a clamping ring, a step bolt, a compression spring, an ejector pin, a clamp cover plate, a pawl, a torsion spring, tension springs, tension spring columns and a handle, wherein the center shaft is located in the center of the base, a spigot is formed in the base and matched with a clamping ring spigot, the clamping ring and the base are provided with the tension spring columns respectively and are connected through the tension springs, a screw hole is formed in the base, the step bolt is installed on the base, the handle is installed on the clamping ring, the clamping ring is provided with notches, the clamping ring and the clamp side pawl form a ratchet wheel self-locking structure, the ejector pin is arranged in the base, a compression spring is arranged on the ejector pin in a sleeving mode, the clamp cover plate is installed on the base and is provided with a through hole for one end of the ejection pin to penetrate through, and the lower surface of the clamp cover plate is in contact with a supporting universal ball. The clamp has the advantages that clamping is simple and fast, positioning is accurate, the welding quality is reliable, the surface smoothness is high, the rejection rate is zero, the production efficiency is high, and the labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

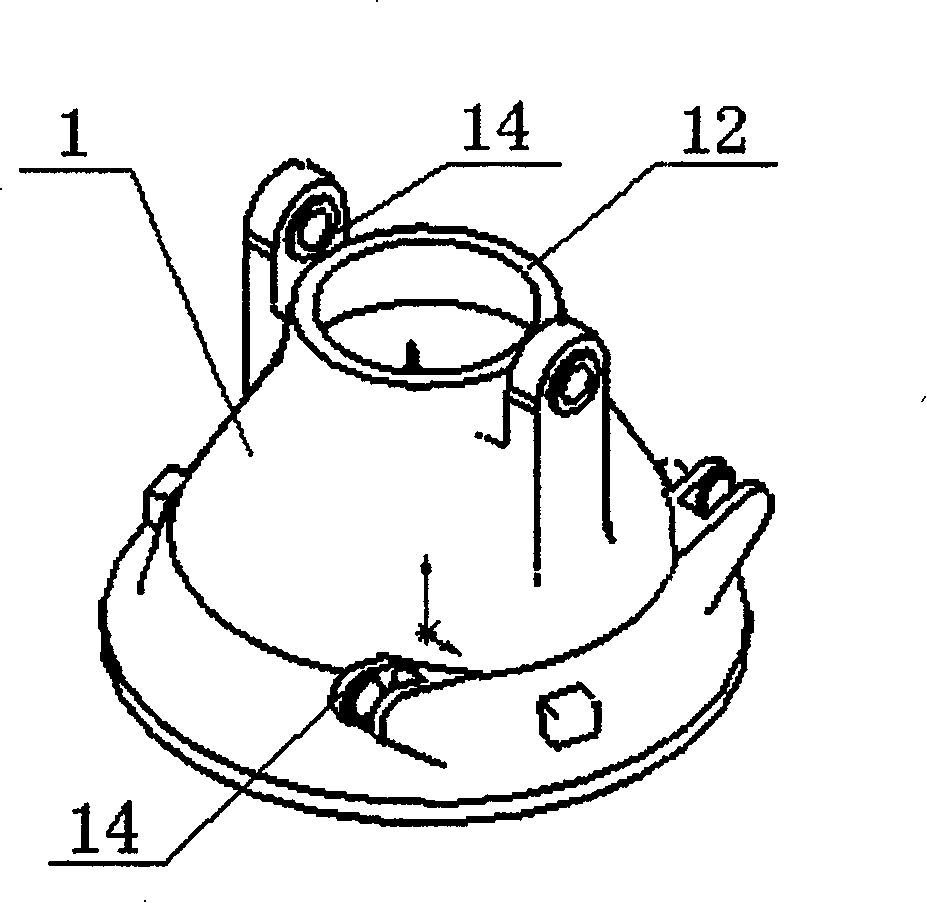

Magnetic yoke loading and unloading clamp

InactiveCN108422129AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesMotor driveGrating

The invention relates to a magnetic yoke loading and unloading clamp. A self-made rotary platform part is installed on a rotary table heightening seat, a material loading clamp and buckle is installedon the top of the self-made rotary platform part, a material pushing part is installed on the side surface of the self-made rotary platform part, the self-made rotary platform part is provided with agrating sensor and a motor, and the self-made rotary platform part is divided into 18 stations; after workpieces fills a magnetic yoke material clip, a stop pin is pulled out, a first station rotatesto an in-placed angle, the workpieces fall into the self-made rotary platform part in sequence, and are pushed out in sequence by the pushing part, the workpieces in a material groove of the first station are reduced, the grating sensor on the self-made rotary platform part cannot detect the workpieces, at the moment, the motor drives the feeding clamp and buckle to rotate clockwise by one angle,the second station enters the working state, the steps are repeatedly operated in sequence until all the workpieces are discharged, and the clamp is suspended to run, and the magnetic yoke material clip filled with the workpieces is arranged on the clamp. The device is accurate in positioning, reliable in welding and high in efficiency.

Owner:WUHAN CHUTIAN IND LASER EQUIP

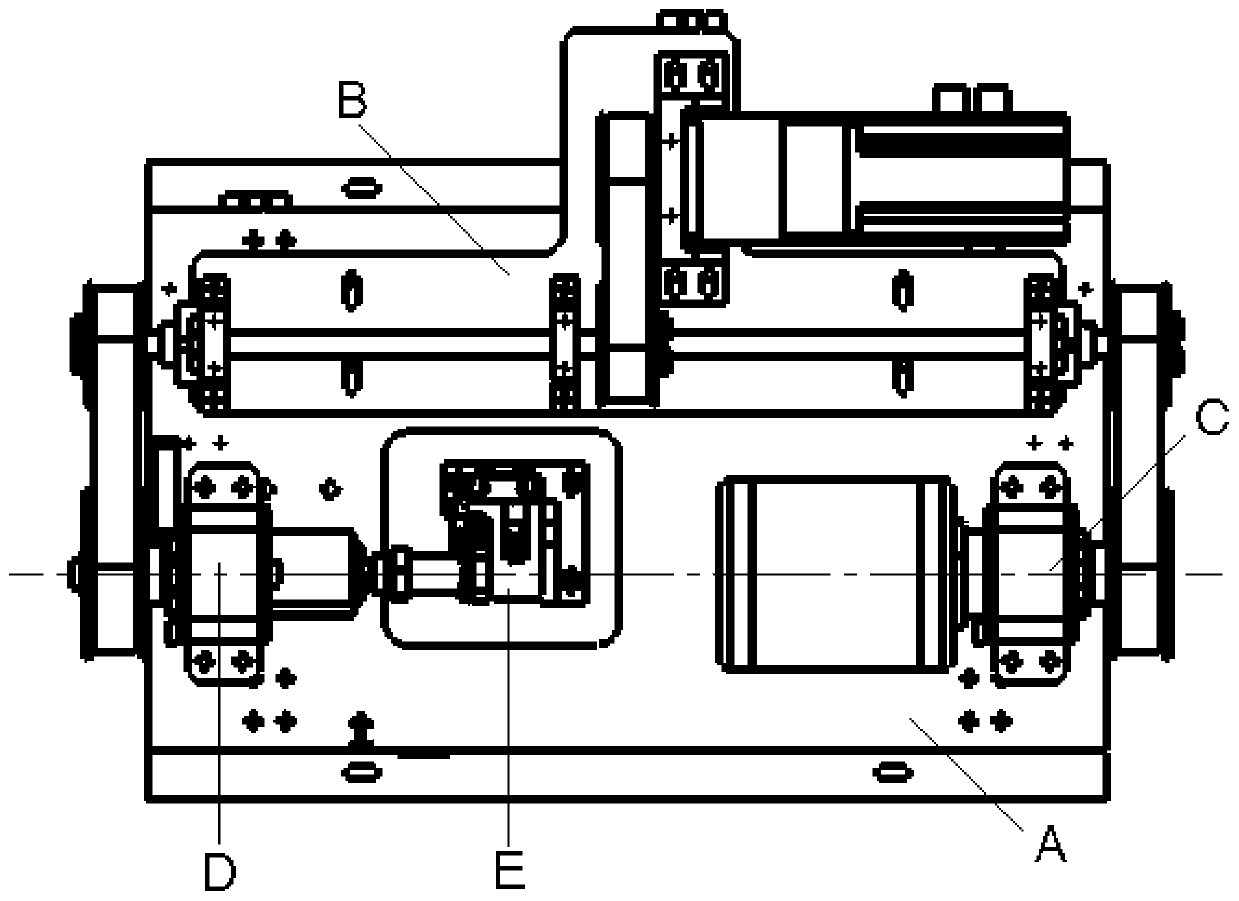

Square oil distributing pipe welding clamping device

ActiveCN108422112AEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention relates to a square oil distributing pipe welding clamping device. A clamping device initial positioning block is arranged over a clamping device bracket. The clamping device bracket andan elastic heightening module are arranged on a clamping device base plate. A left positioning block, a front positioning block, a rotating cylinder, a clamping cylinder, a pressuring head, a stopping screw, a miniature cylinder, a cylinder mounting base, and a positioning pin are arranged over the clamping device initial positioning block. The clamping device initial positioning block and the clamping device bracket are connected through a reinforced connecting block. The clamping device initial positioning block and the functional mounting base plate are connected through a reinforced connecting block. A clamping block is arranged on the clamping cylinder and is arranged opposite to the left positioning block. The positioning pin is arranged on the miniature cylinder. The miniature cylinder is arranged on the cylinder mounting base. The pressuring head is arranged on the rotating cylinder. The rotating cylinder is arranged beside the left positioning block. The clamping device is simple and fast to use, and has accurate positioning, high welding efficiency, low labor intensity, firm welding, nice appearance, and a low disability rate. The clamping device reduces production costand improves production efficiency.

Owner:WUHAN CHUTIAN IND LASER EQUIP

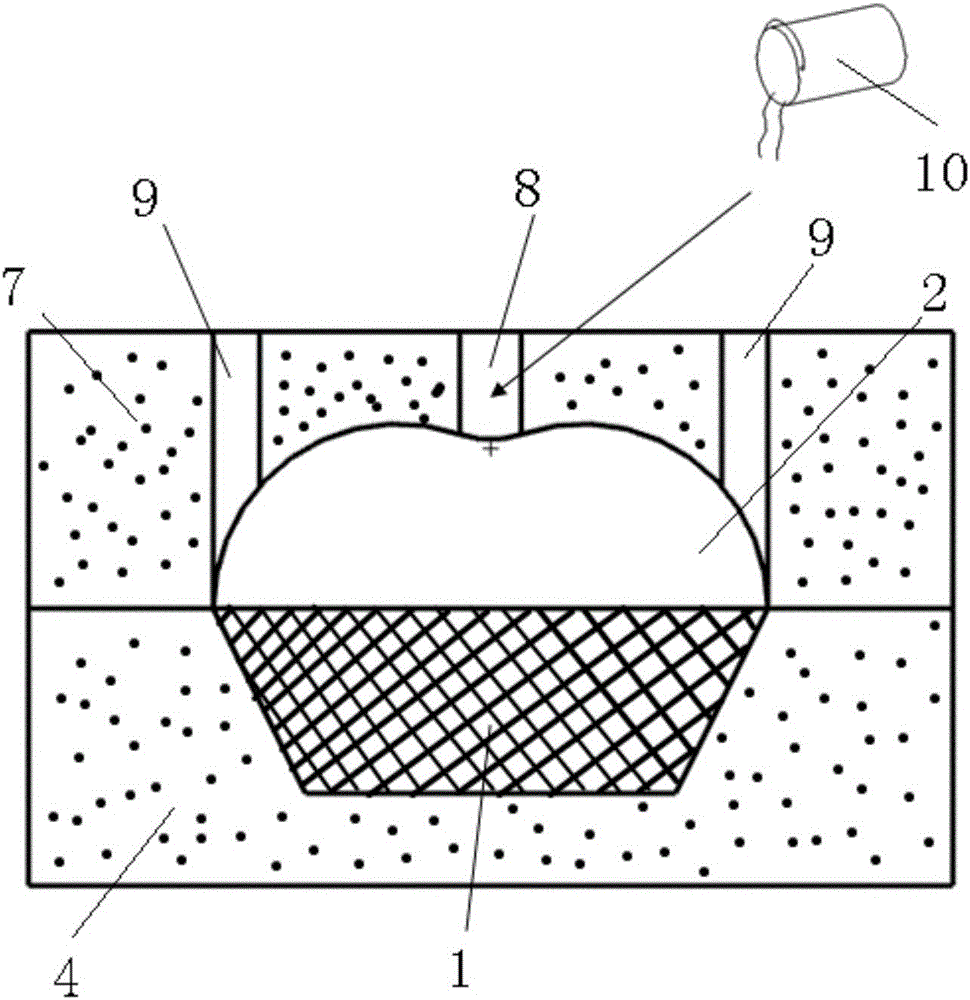

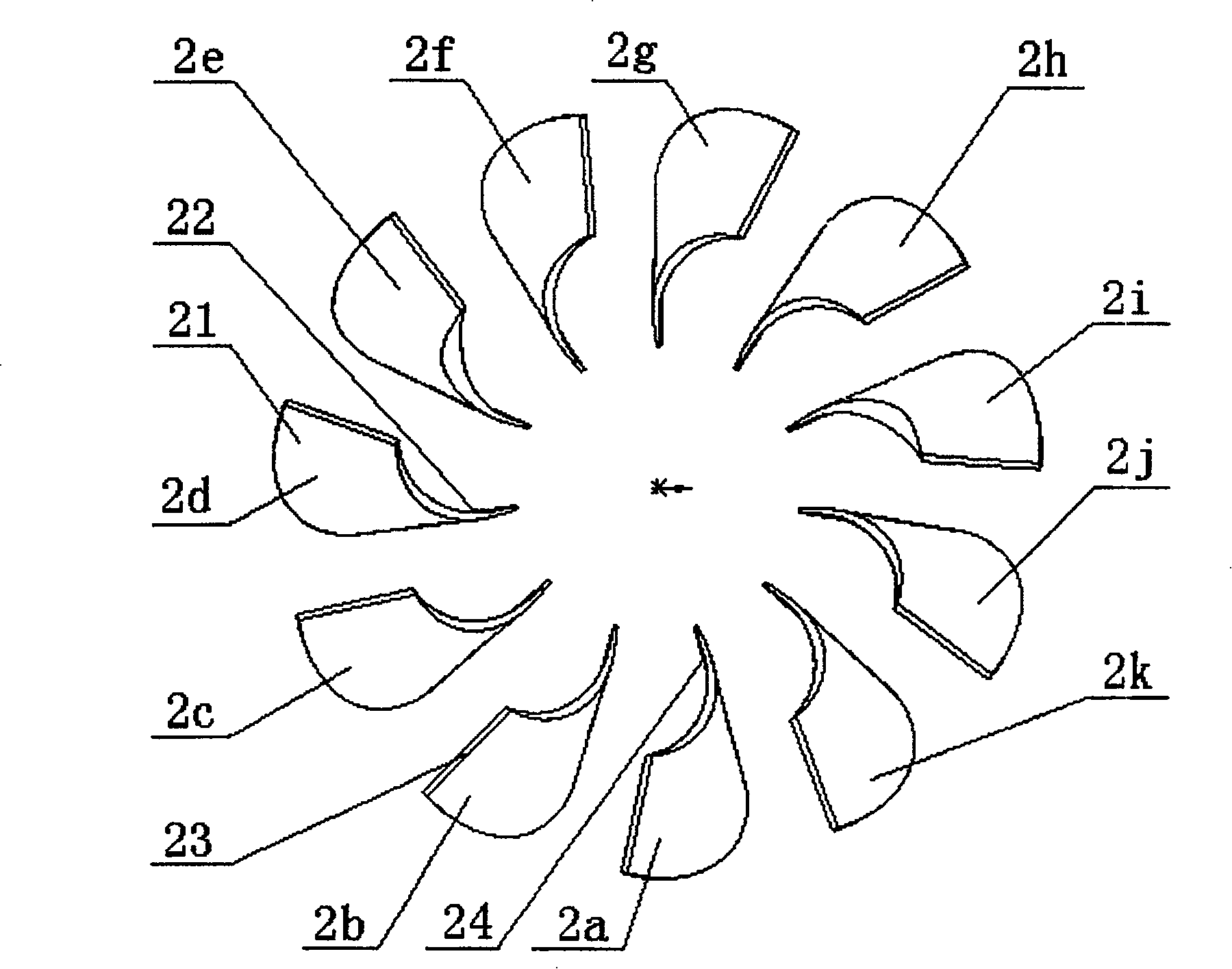

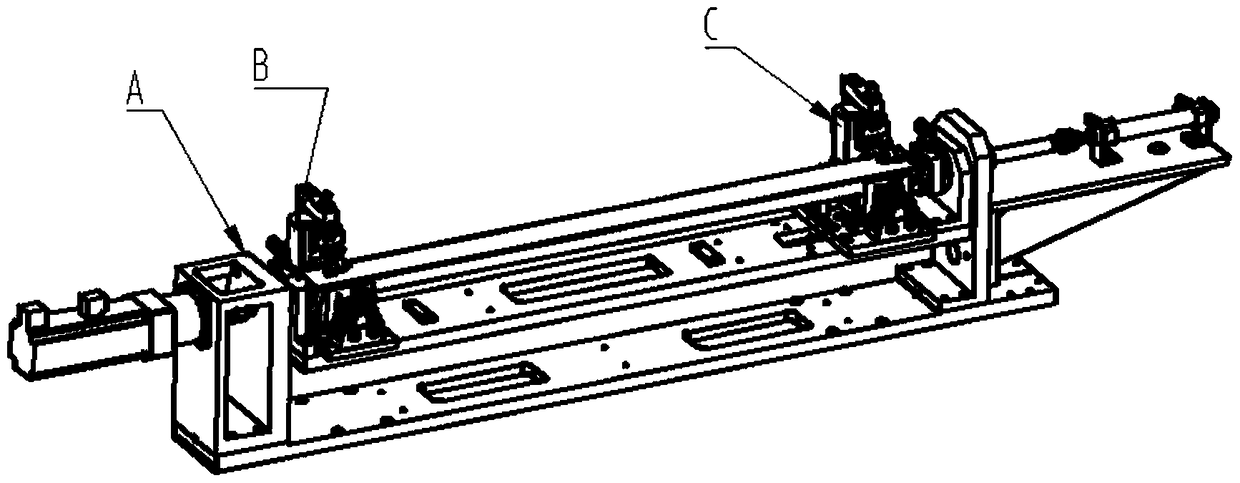

Water jet propelling device guide blade processing method

InactiveCN100406348COvercome the problem that the line type is difficult to guaranteeImprove type value control abilityGeometric arrangementsPropulsive elementsInternational standardDouble phase

The invention relates to a method for processing the blades of injection propulsion unit, wherein it controls the process allowance of casting element, to improve the check and machine on each shaping surface of blade 2; it uses ultrasonic wave detector to detect the wall thickness of oil hole 25, improve the accuracy of curvature of blade 2 in double-phase stainless blade 1, and the control ability of blade 2; the processing accuracy of long lubricant hole of blade 2 is improved, to improve the process efficiency and accuracy of blades 1, 2. The invention's quality can reach international standard.

Owner:WUHAN MARINE MACHINERY PLANT

Processing method of rolling mill archway

The invention discloses a processing method of a milling housing. A first plum blossom hole is formed in the housing and formed through cutting machining and abrasive machining on a housing substrate. The processing method is characterized in that during the cutting, the empirical formula of a cutting speed is as follows: V=3.14*D*n*eta<2> / 1000, wherein V represents the cutting speed with a unit of m / min; n represents the revolving speed of a machine tool spindle with a unit of rpm; D represents a cutting radius ranging from 260mm to 360mm; eta<2> is a coefficient ranging from 0.05 to 0.08; the smaller the difference between the size of the plum blossom hole and a design value is, the larger the value of the plum blossom hole is; and otherwise, the value of the plum blossom hole is smaller. By means of the processing method of the mill housing, the mill housing which meets the accuracy requirement can be processed. According to the processing method, the dimensional tolerance of diagonal plum blossom holes of the mill housing are smaller than or equal to 0.01mm, the total tolerance is smaller than or equal to 0.02mm, and the straightness of each hole is smaller than or equal to 0.01mm. With the adoption of the method for processing the housing, under the condition that smooth and efficient processing is guaranteed, the housing substrate cannot be scrapped, and the scrappage rate is zero under the condition that the processing efficiency is improved by over 20%.

Owner:上海山弈冶金技术有限公司

A square oil distribution pipe welding fixture

ActiveCN108422112BEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPipe welding

The invention relates to a square oil distributing pipe welding clamping device. A clamping device initial positioning block is arranged over a clamping device bracket. The clamping device bracket andan elastic heightening module are arranged on a clamping device base plate. A left positioning block, a front positioning block, a rotating cylinder, a clamping cylinder, a pressuring head, a stopping screw, a miniature cylinder, a cylinder mounting base, and a positioning pin are arranged over the clamping device initial positioning block. The clamping device initial positioning block and the clamping device bracket are connected through a reinforced connecting block. The clamping device initial positioning block and the functional mounting base plate are connected through a reinforced connecting block. A clamping block is arranged on the clamping cylinder and is arranged opposite to the left positioning block. The positioning pin is arranged on the miniature cylinder. The miniature cylinder is arranged on the cylinder mounting base. The pressuring head is arranged on the rotating cylinder. The rotating cylinder is arranged beside the left positioning block. The clamping device is simple and fast to use, and has accurate positioning, high welding efficiency, low labor intensity, firm welding, nice appearance, and a low disability rate. The clamping device reduces production costand improves production efficiency.

Owner:WUHAN CHUTIAN IND LASER EQUIP

Helicopter composite material paddle fatigue test piece molding method

InactiveCN102507275BImprove the passing rate of one-time inspectionZero scrap rateMachine part testingPreparing sample for investigationNumerical controlRejection rate

The invention belongs to a composite material molding technology, and relates to helicopter composite material paddle fatigue test piece molding technological process which is suitable for helicopter composite material technological process molding. According to the invention, a platform thickness spacing tool is adopted, an interval between two splints of a paddle fatigue test piece is effectively ensured, and simultaneously the positioning of the spacing tool can insure symmetry of the two splints; and a working procedure of numerical control processing is directly omitted from a technical process, furthermore a manufacturing cycle is also shortened, once alternating detection qualification rate of the paddle fatigue test piece is improved, the rejection rate of the paddle fatigue test piece is zero, and the stability and the smoothness of the assembly process of the paddle fatigue test piece are ensured.

Owner:中航直升机股份有限公司

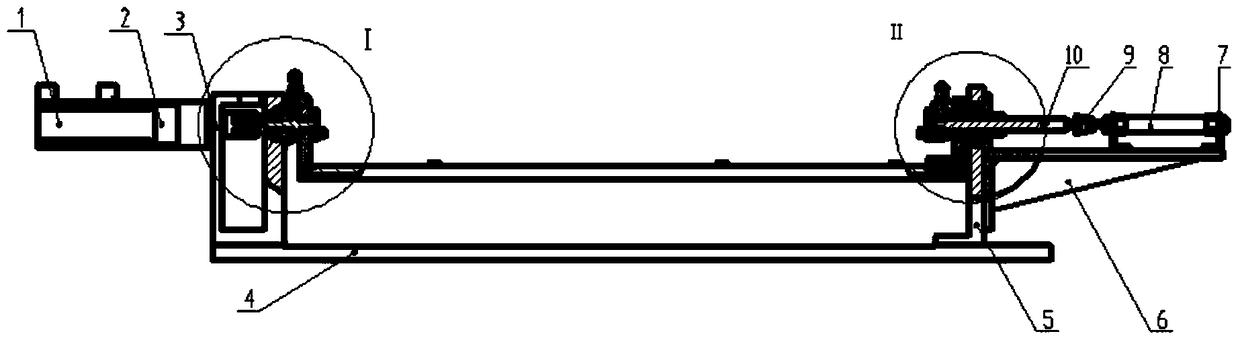

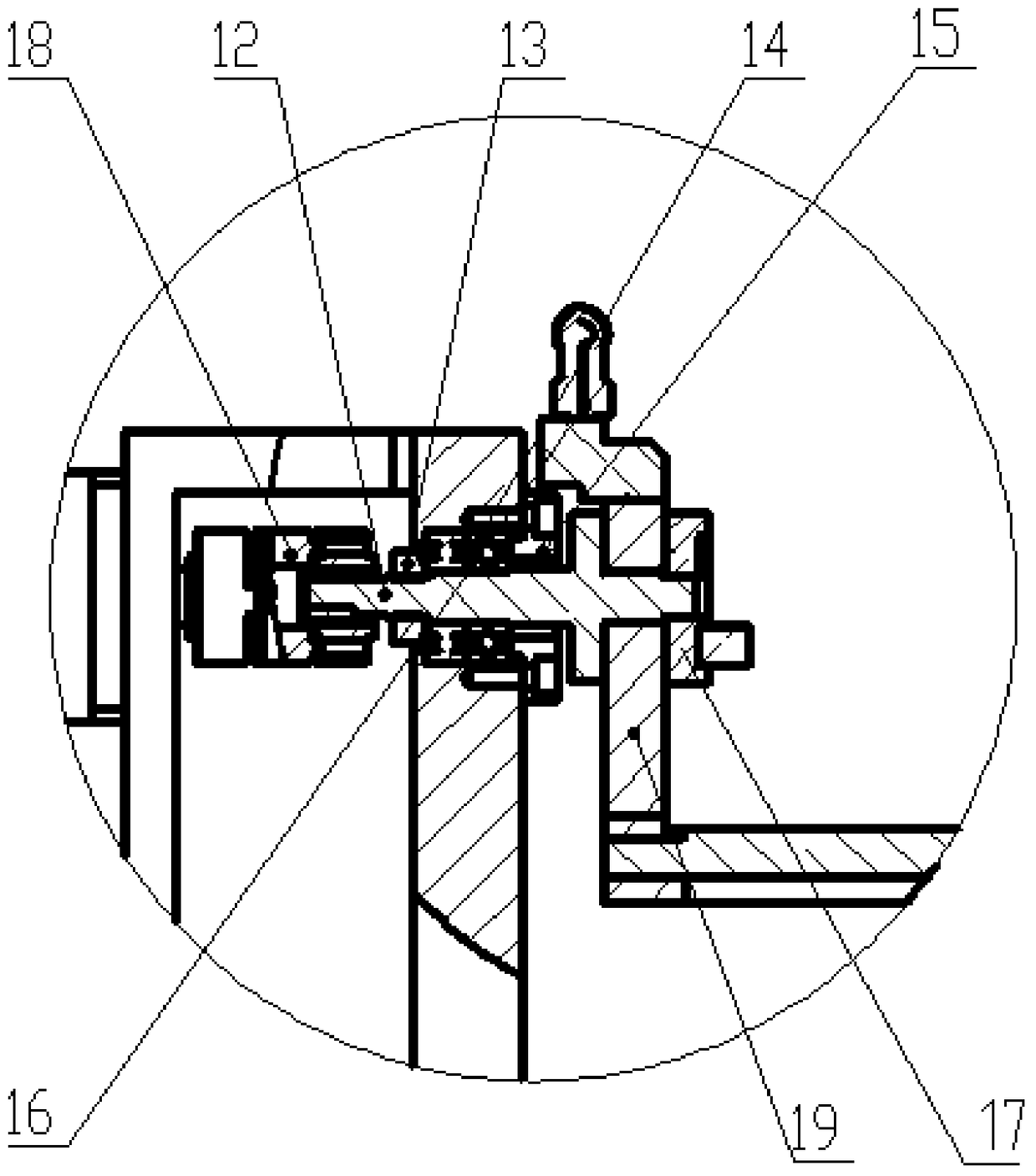

A sensor welding jig

ActiveCN108422083BEasy and fast clampingPrecise positioningLaser beam welding apparatusEngineeringPulley

The invention relates to a sensor welding fixture. The sensor welding fixture comprises a base component, an electrical machine rotating component, a wire winding servo component, a rotating componentand a rest component. The electrical machine rotating component, the wire winding servo component, the rotating component and the rest component are separately installed on the base component, the electrical machine rotating component is connected with the rotating component and the wire winding servo component through two belt pulleys, and the rotating component is connected with the rest component. The device has advantages of accurate positioning, reliable welding, high efficiency and zero disability rate.

Owner:WUHAN CHUTIAN IND LASER EQUIP

Directional and automatic-control bending machine and operation method thereof

The invention discloses a directional and automatic-control bending machine. The machine comprises a rack, a working plate, an insertion base, a transmission mechanism and a limiting switch, wherein a table plate is arranged on the rack; the working plate is rotationally arranged on the table plate, a round central sleeve is arranged in the middle of the working plate, a central sleeve shaft is arranged in the central sleeve, and a round forming sleeve and a sleeve bearing matched with the forming sleeve are further arranged on the working plate; the insertion base is fixedly arranged on the table plate, and a bar blocking frame is arranged on the insertion base; the transmission mechanism drives the working plate to rotate around the central sleeve shaft; the limiting switch is arranged on the table plate and can be used for setting the rotation angle of the working plate. The steel bars machined by the directional and automatic-control bending machine have the same bending degree and are attractive in appearance, the rejection ratio is zero, the work efficiency is high, little labor force is required, the labor intensity is low, and besides, a method is scientific, efficient, safe and simple.

Owner:中铁武汉电气化局集团第一工程有限公司

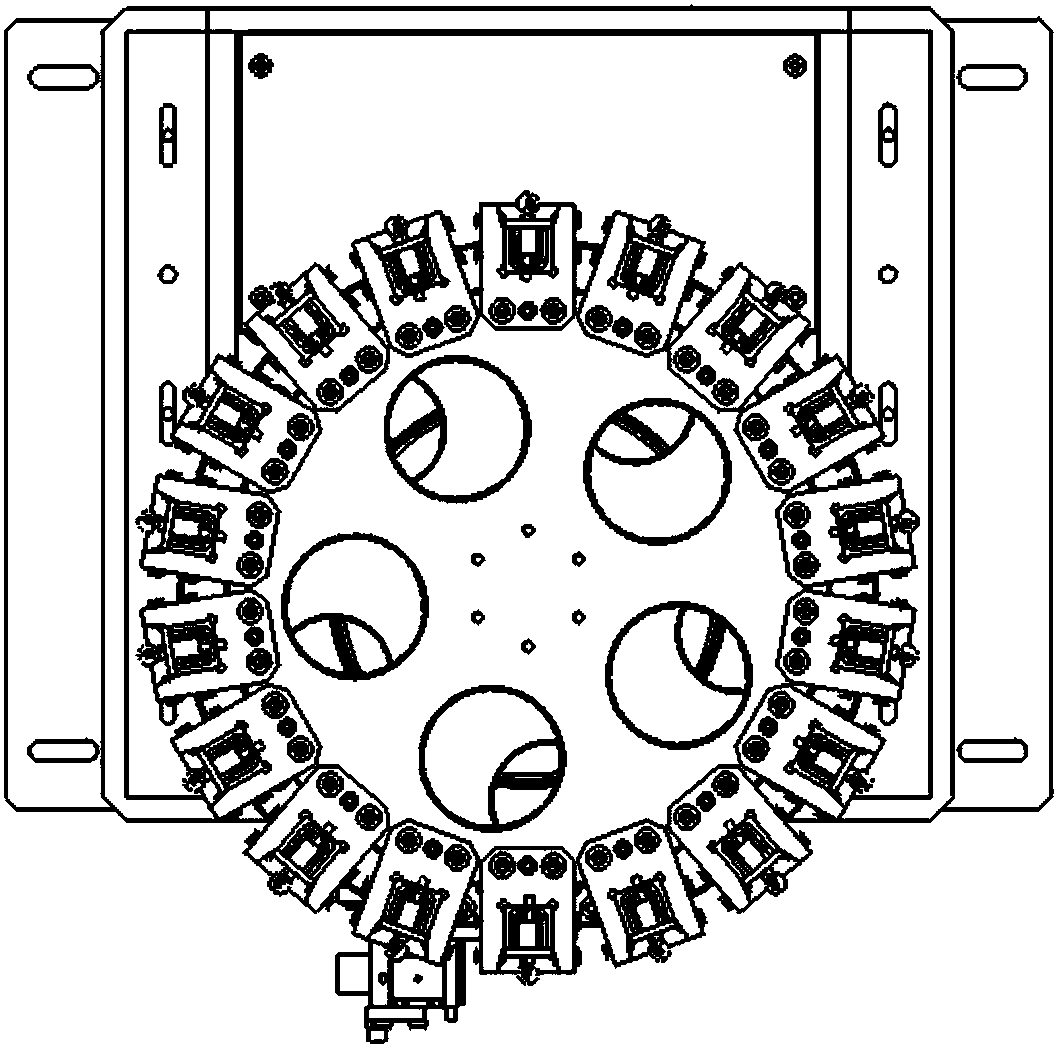

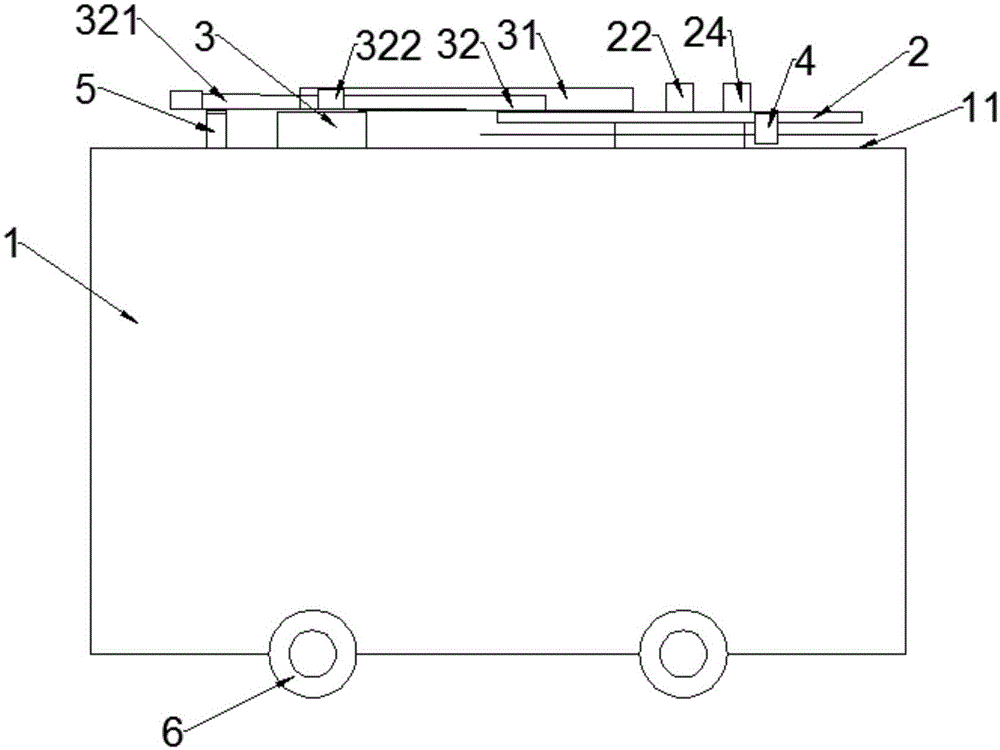

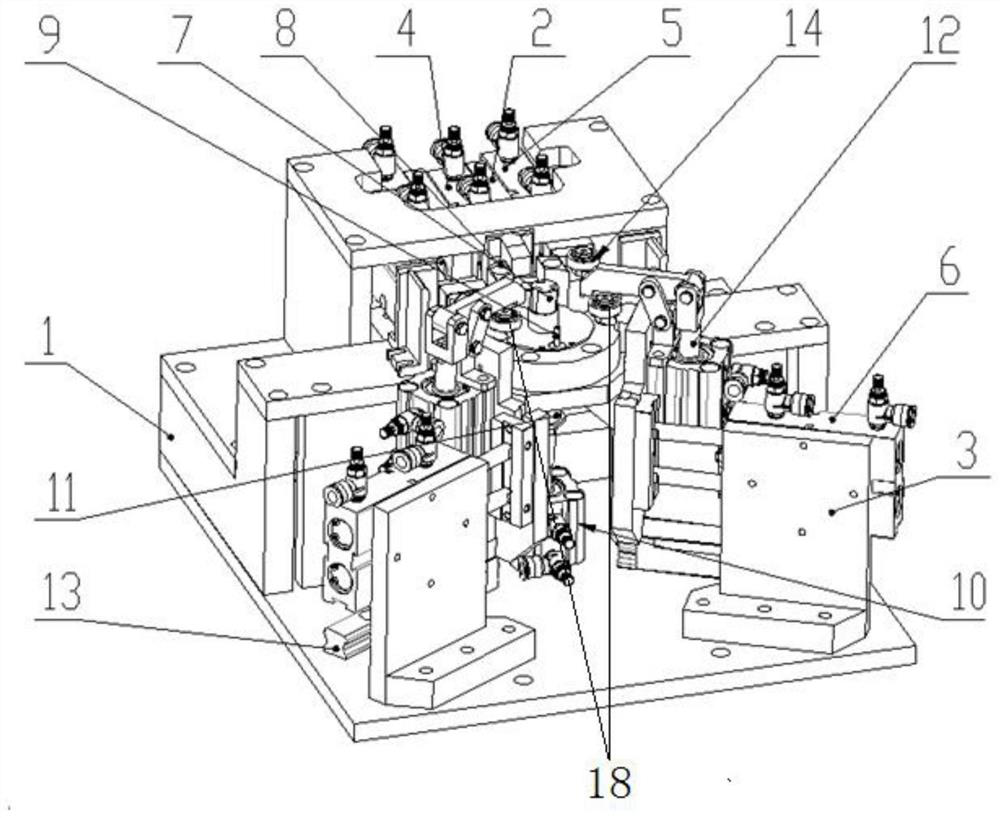

Motor stator automatic bending forming welding fixture

ActiveCN112475641BEasy and fast clampingPrecise positioningElectric machinesLaser beam welding apparatusElectric machineStructural engineering

The invention relates to an automatic bending and forming welding fixture for a motor stator. It is fixed on the fixture bracket, two bending and one-time forming cylinders are respectively installed on the two bending and one-time forming cylinder mounting plates, and two one-time forming bending bearings are respectively installed on the front ends of the two bending and one-time forming cylinders. The secondary forming cylinders are respectively installed on the two bending secondary forming cylinder mounting plates, and the two secondary forming bending bearings are respectively installed on the front ends of the two elbow clamp cylinders. The elbow clamp cylinder is installed above the linear guide rail, and the centering module passes through The ejector pin is connected with the jacking cylinder, and the positioning module and the height-fixing module are located on both sides of the centering module. The invention is simple, quick, accurate in positioning, can realize rapid welding in combination with the laser welding process, has high welding quality, zero scrap rate, high production efficiency and low labor intensity.

Owner:WUHAN ZHONGGU POWER SUPPLY DEVICE

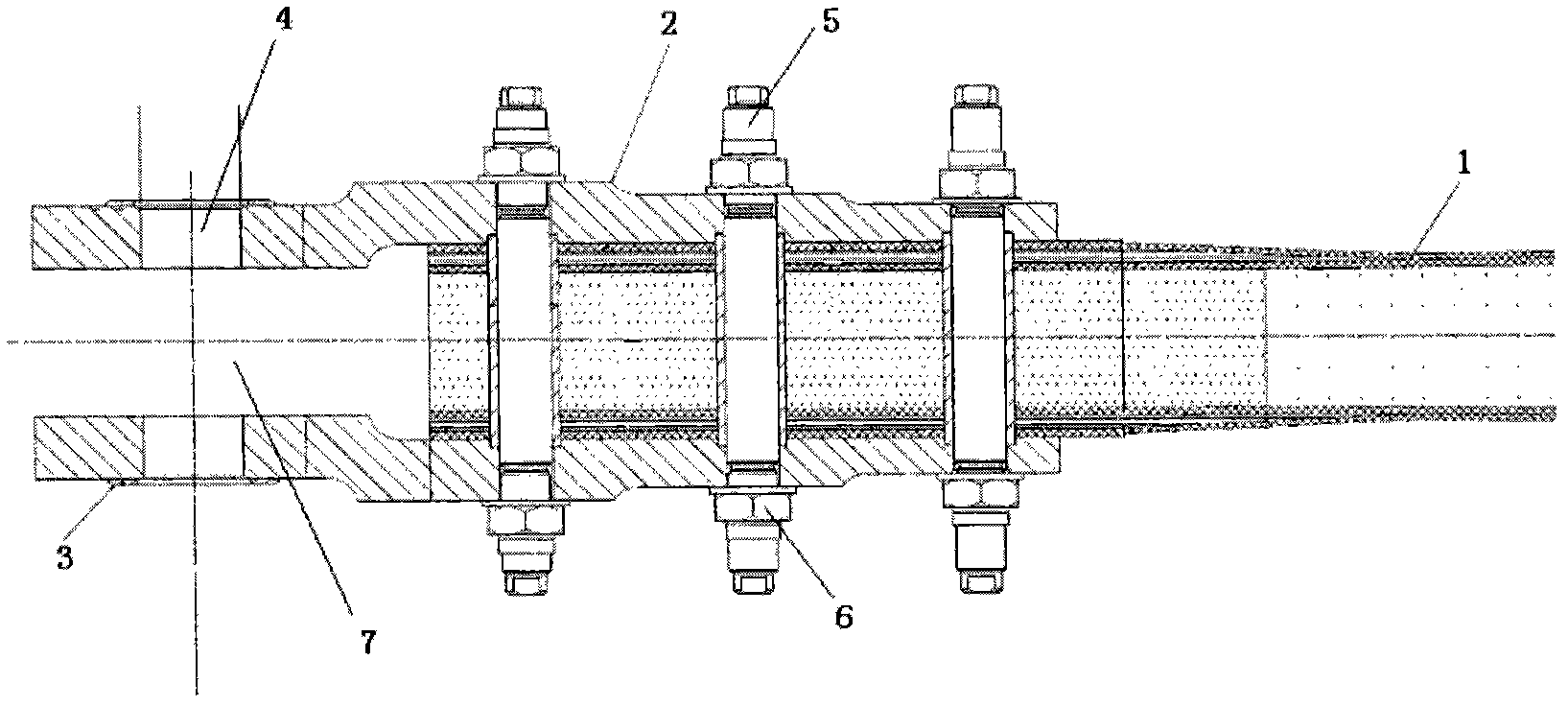

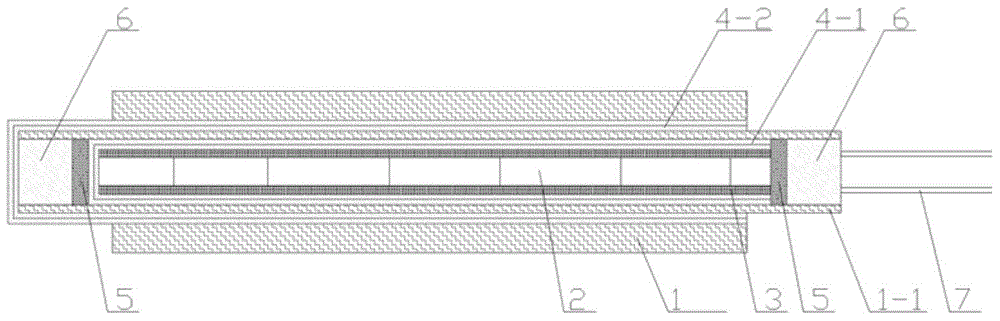

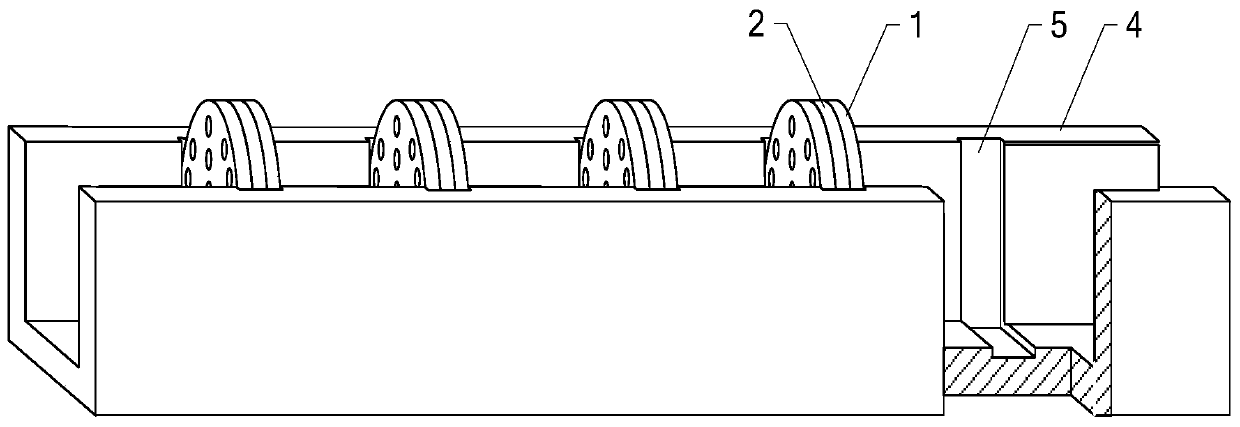

Liquid PTC heating unit whose power is adjusted conveniently

ActiveCN105828469AZero scrap rateHeating safetyOhmic-resistance heating detailsImmersion heating arrangementsThermodynamicsElectrical and Electronics engineering

The invention provides a liquid PTC heating unit whose power is adjusted conveniently, which comprises two PTC heating sheet assemblies and a heating unit aluminous shell coating the two PTC heating sheet assemblies, wherein each PTC heating sheet assembly comprises a plurality of PTC heating sheets, two insulated layers and a heating sheet assembly aluminous shell; the PTC heating sheets and electrode sheets at the upper ends and the lower ends are coated by the first insulated layer; the first insulated layer is coated by the heating sheet assembly aluminous shell; the heating sheet assembly aluminous shell is coated by the second insulated layer; and a locking mechanism is arranged in the middle of an upper plate and a lower plate of the heating unit aluminous shell for changing contact areas between the upper plate and the lower plate and the PTC heating sheet assemblies. The power of the PTC heating unit can be adjusted, the production cost is reduced, the rejection rate is nearly zero, and the operation is safer and more reliable.

Owner:JIANGSU YOUMAY ELECTRIC APPLIANCE

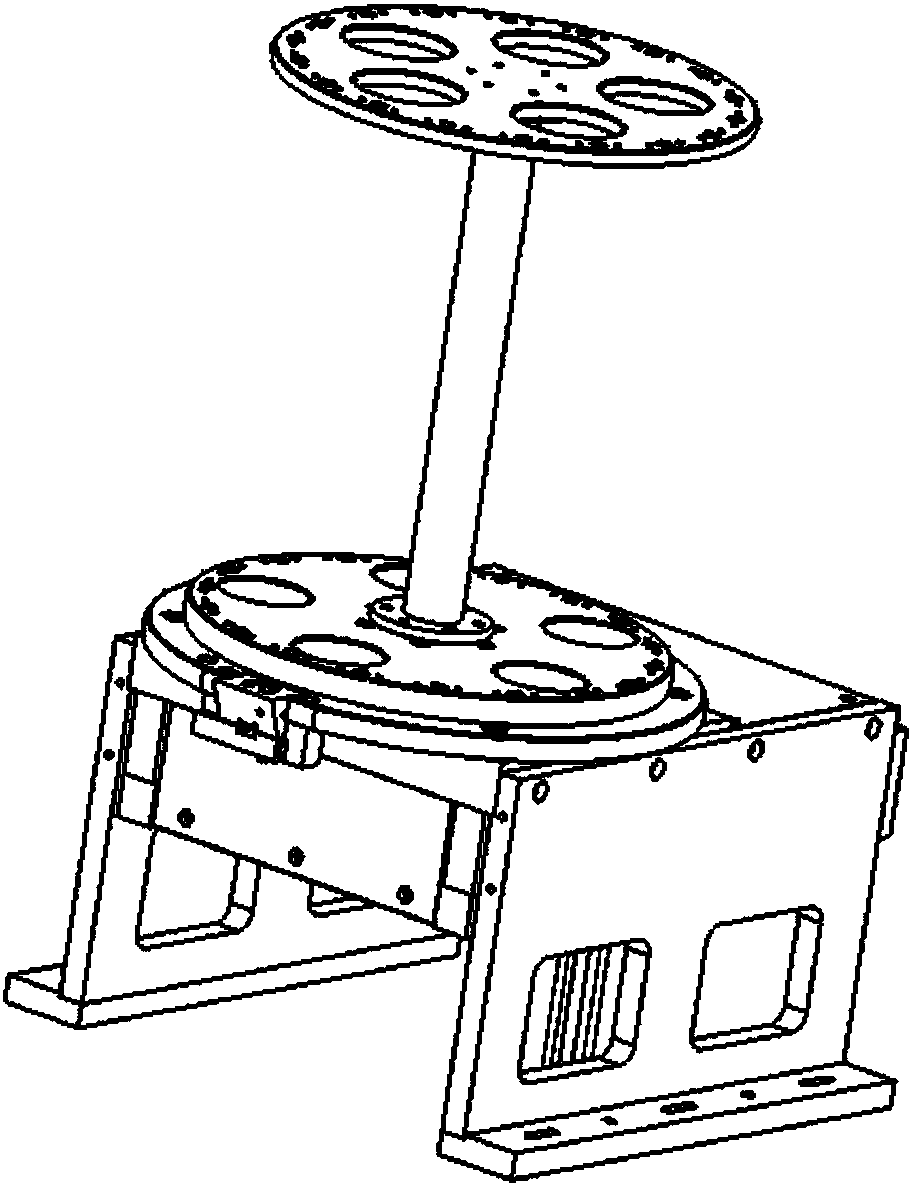

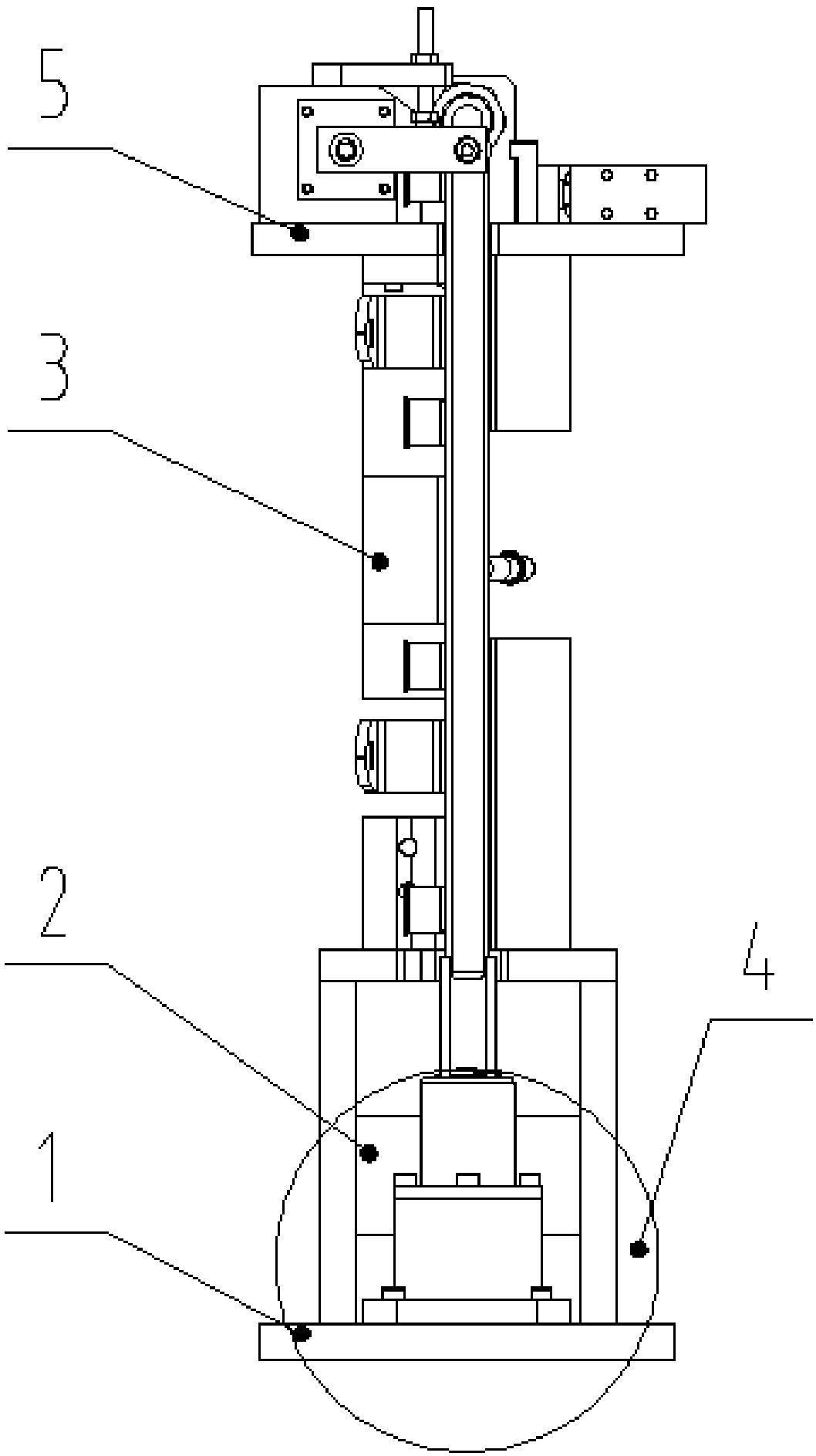

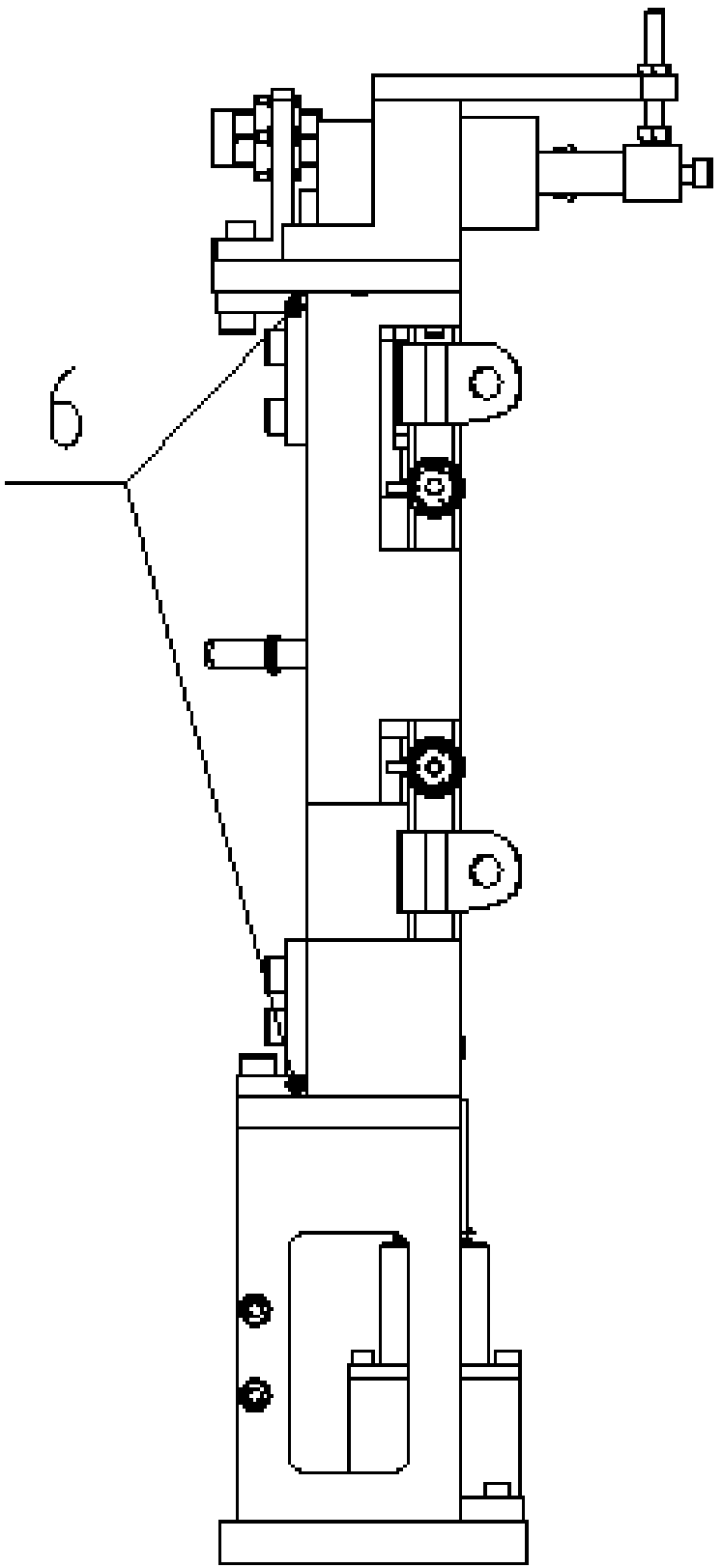

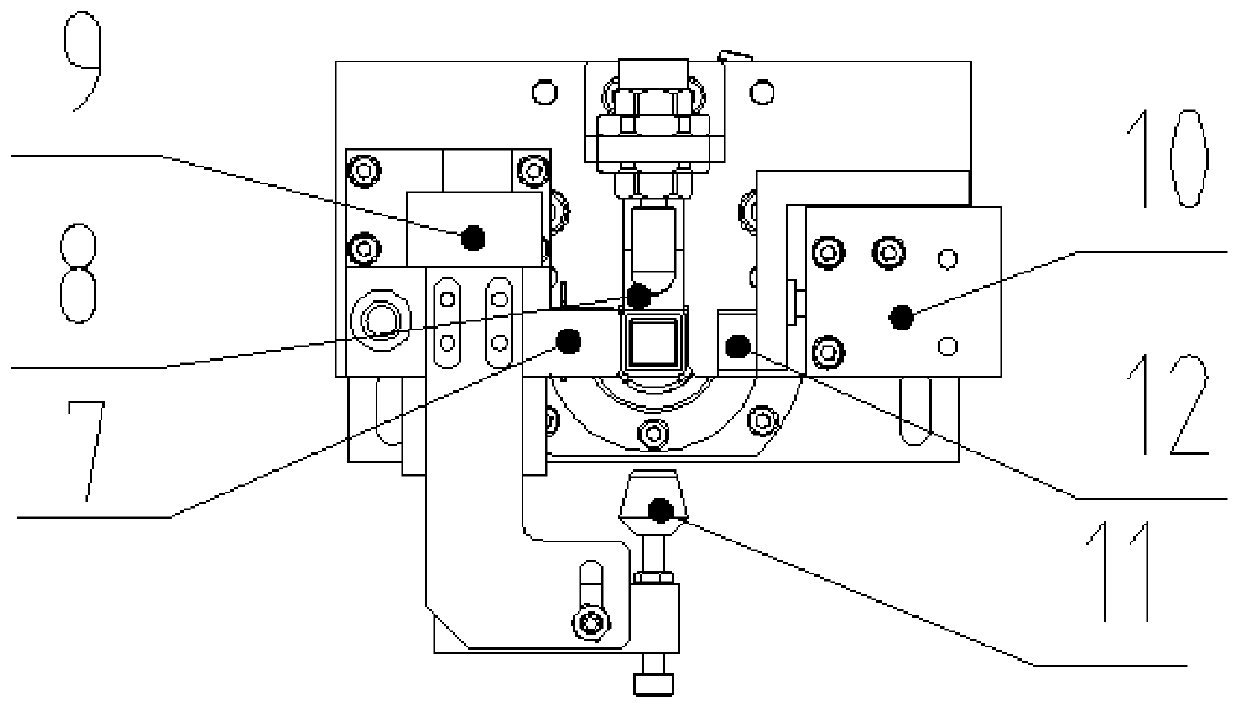

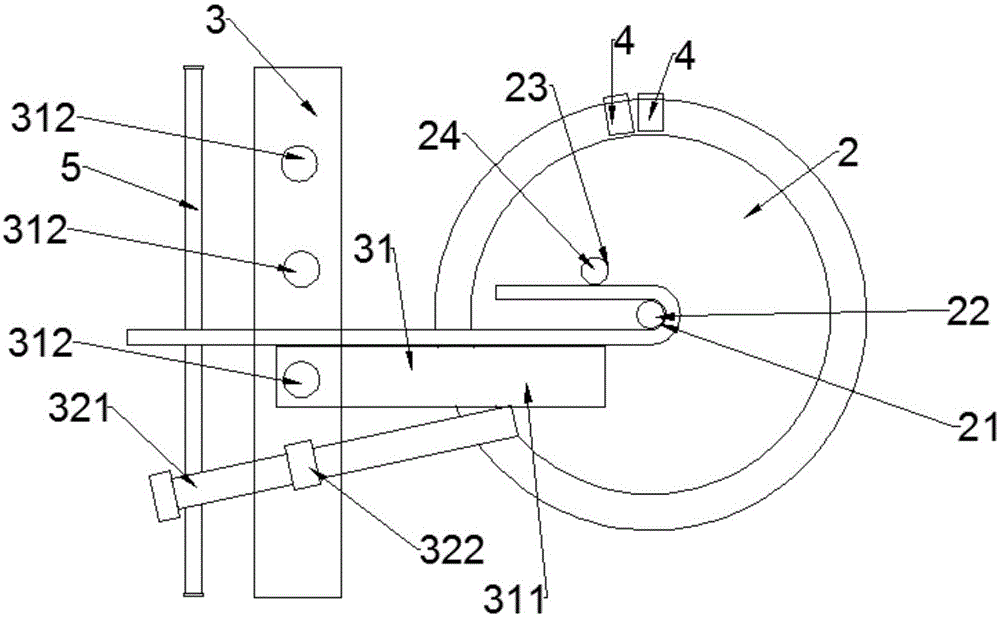

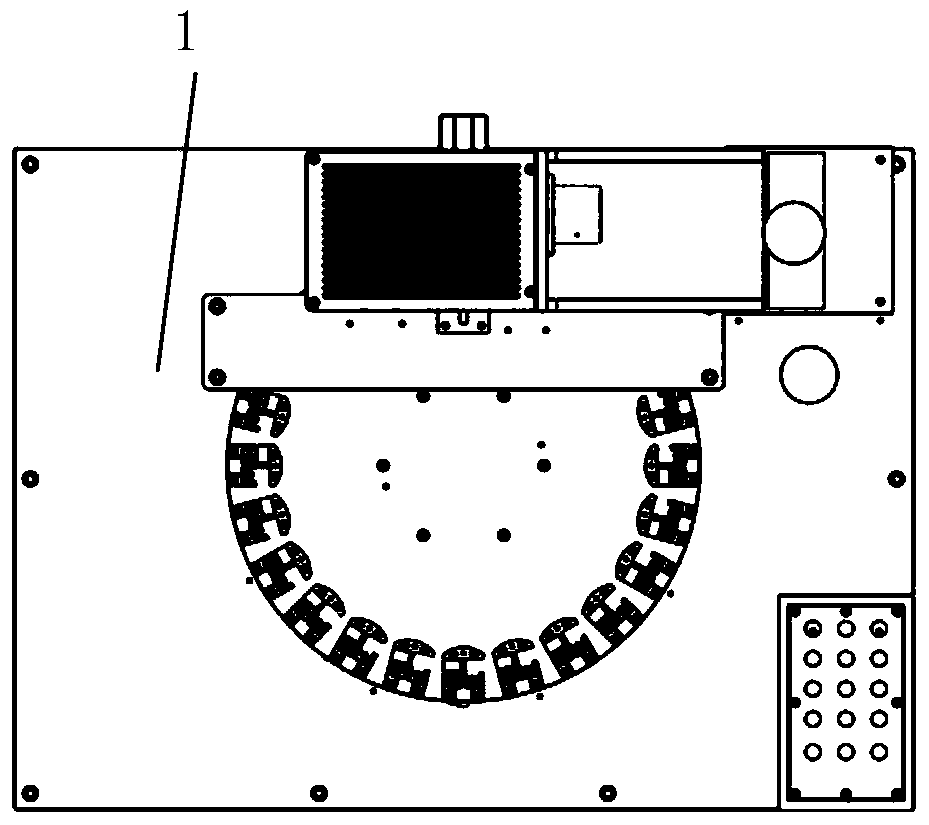

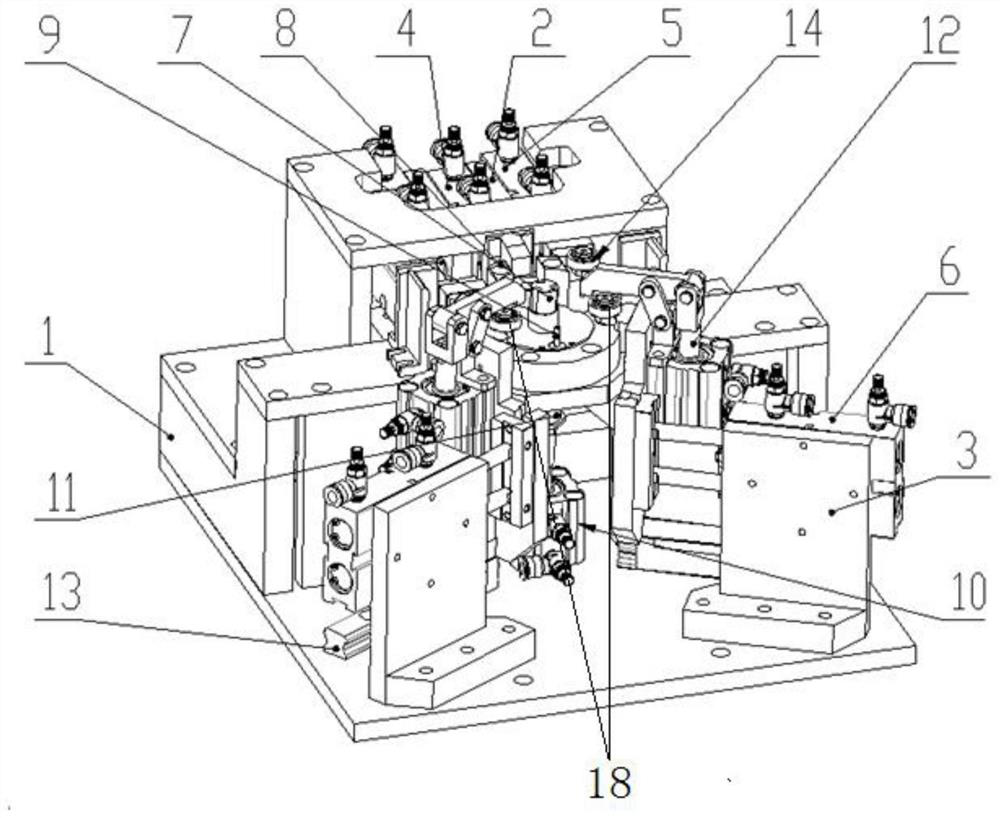

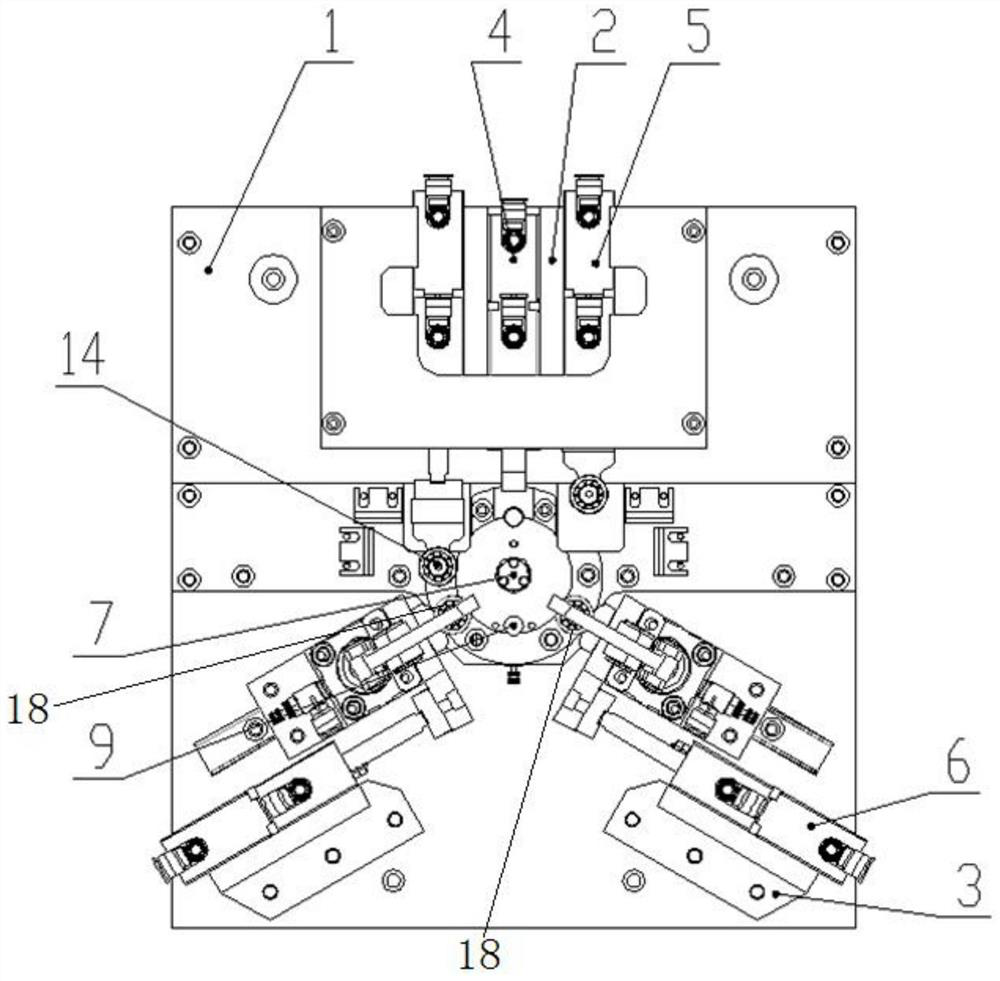

A turntable fixture

ActiveCN106944786BEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesSurface finishGalvanometer

The invention relates to a turnplate fixture. The turnplate fixture comprises a turnplate assembly, a galvanometer lifting assembly, a galvanometer welding head assembly, a pressing assembly, a follow fixture body and a discharging assembly, wherein the follow fixture body is fixed to the turnplate assembly, the pressing assembly is located above the follow fixture body, the discharging assembly is located below the follow fixture body, the galvanometer lifting assembly is fixed to a big platen, the turnplate assembly and the discharging assembly are both mounted on the big platen, and the galvanometer welding head assembly is connected with the galvanometer lifting assembly. Compared with a traditional welding device, the turnplate fixture has the advantages that clamping is easy and fast, and positioning is accurate; through the modern laser welding technique, rapid welding can be achieved, and the welding quality is reliable; and the surface smoothness is high, the rejection rate is zero, the production efficiency is high, and the labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

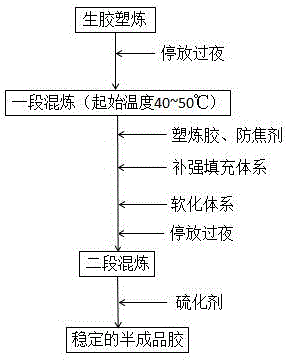

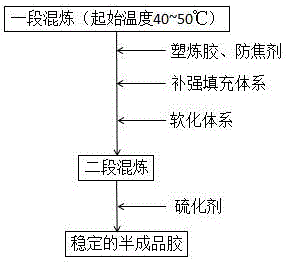

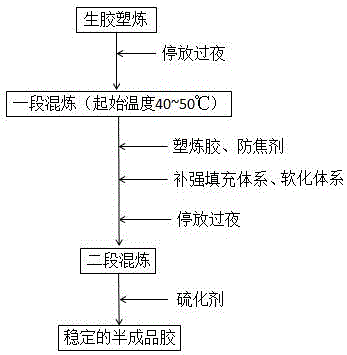

A kind of chloroprene rubber mixing process

The invention discloses a chloroprene rubber mixing process. The chloroprene rubber mixing process comprises the following steps: thin passing and plastifying of chloroprene rubber: the chloroprene rubber is put on an open mill, is weighed and coiled to form a plastified rubber coil after 5 times of thin passing treatment, and is placed overnight; the distance of two rollers of the open mill is controlled within 1-1.5 mm; and the temperature of the rollers is below 50 DEG C; first-stage banburying: after a banbury mixer is heated to 40-50 DEG C, the plastified rubber coil placed overnight is put in the banbury mixer, and scorch retarder is added for mixing 1 minute; reinforcement filling agent is added; and when the temperature is raised up to 71-79 DEG C, softening agent is added for mixing; first-stage rubber discharge: the rubber discharge time is determined according to the temperature and power change to perform the rubber discharge; and the rubber is placed overnight; and second-stage banburying: the mixed rubber placed overnight is put in the banbury mixer again, and vulcanizing agent is added to mix for 60 seconds; and then the rubber discharge is performed to obtain a semi-finished product. The chloroprene rubber mixing process, disclosed by the invention, is smooth in surface, and has no unevenly dispersed ripe particles or other particles.

Owner:上海蓝昊电气江苏有限公司

Vehicle shock absorber piston rod spraying technology

ActiveCN103147033BImprove bindingGood coating strengthMolten spray coatingWorking environmentPiston rod

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

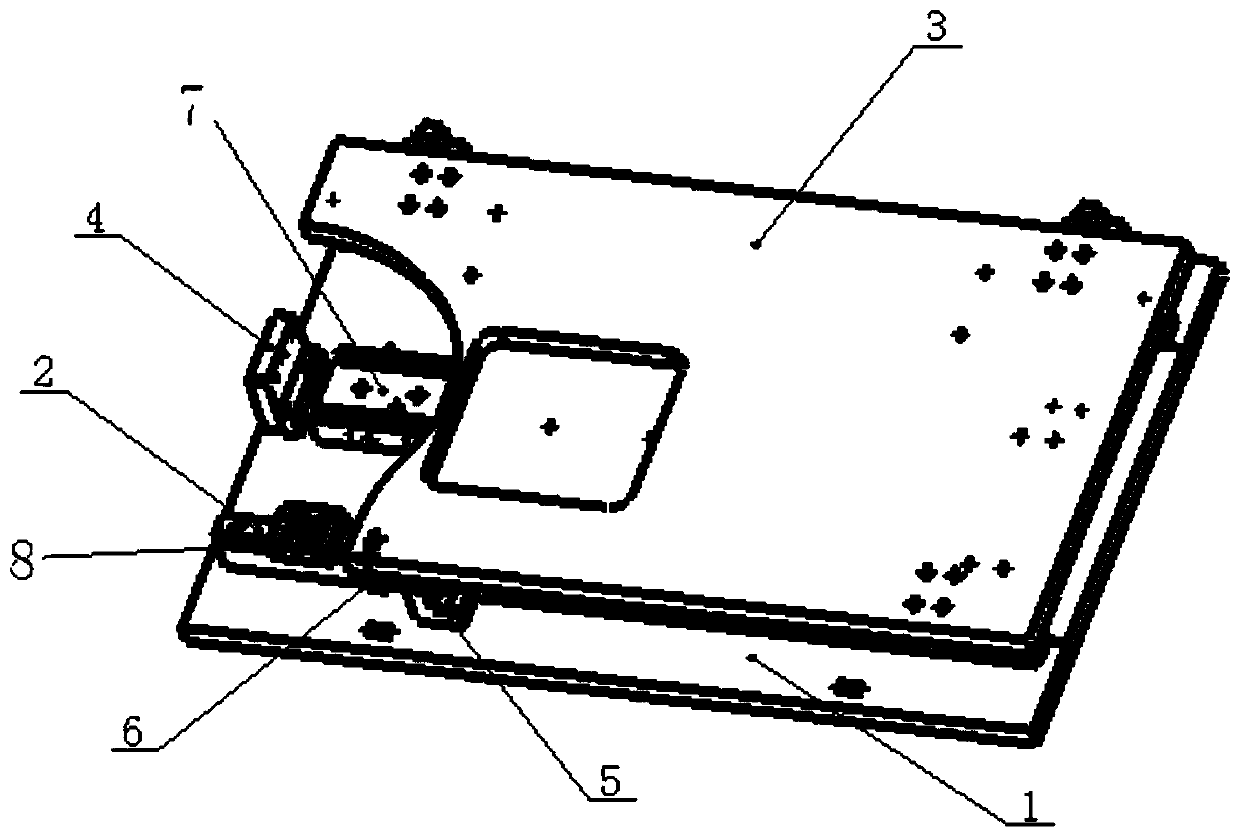

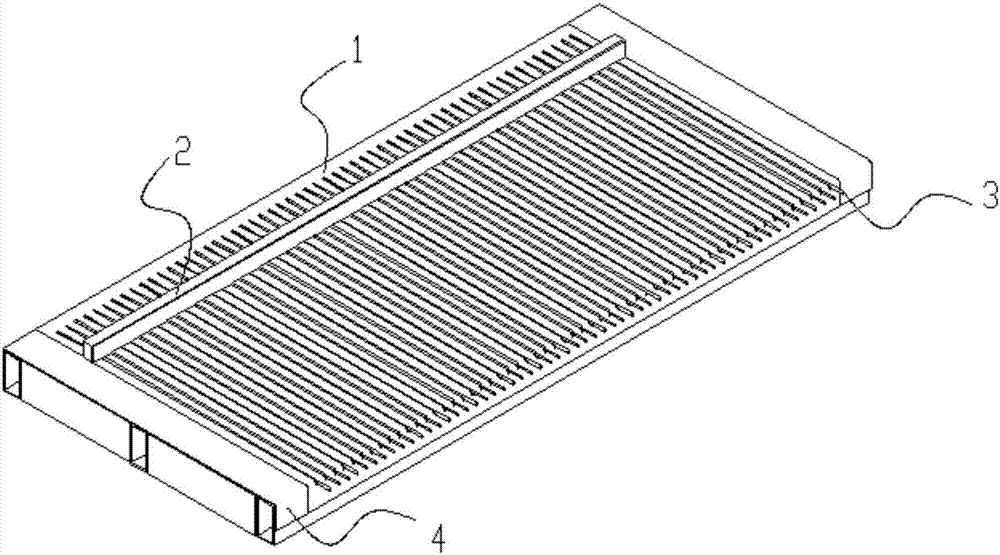

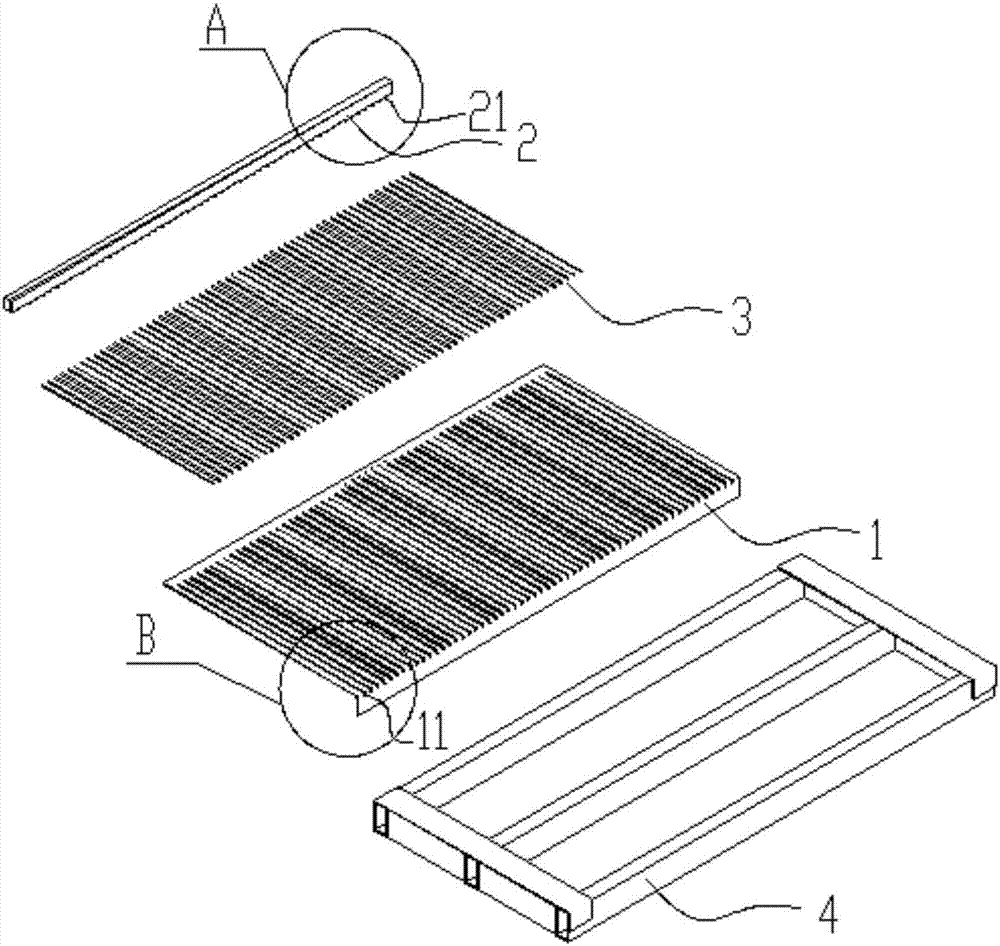

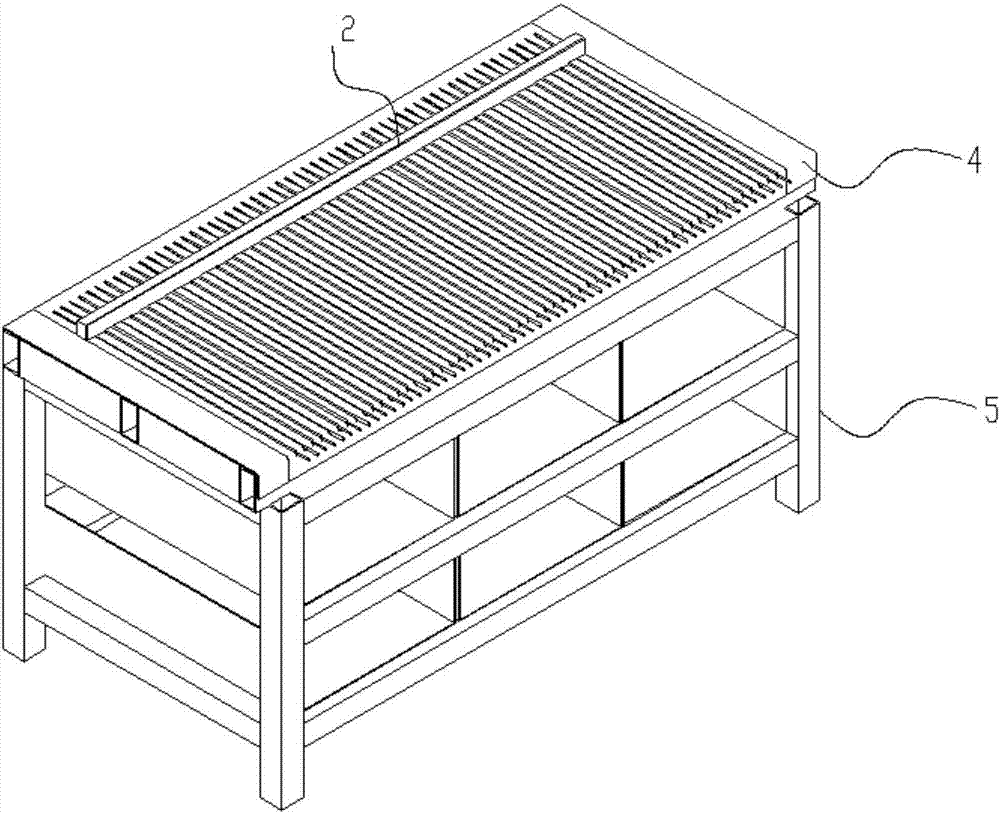

Wiring platform

The invention discloses a wiring platform, which can be a manual wiring platform or an automatic wiring platform. The manual wiring platform includes a material swing platform and a width adjustment bar. The groove can only accommodate one material rod, and also includes a bracket platform and a material rack supporting the swing platform. In addition to the manual wiring platform, the automatic routing platform is also provided with a pushing mechanism and a power device connected with the pushing mechanism. The manual wiring platform of the present invention can realize that the operator pushes the material rods on the material swing platform with bare hands or with the help of tools, and the material rods will automatically fall into the wire groove one by one; the automatic wiring platform is based on the manual wiring platform. Automation, the power device drives the pushing mechanism to automatically complete the material placement process on the material placement platform, which can be operated by one person and multiple machines; the above two wiring platforms not only reduce the dependence of placement on manual skills, save manpower, but also have high placement efficiency , The scrap rate is almost zero.

Owner:QINLONG METAL IND KUNSHAN

A ratchet locking impeller welding fixture with auxiliary feeding function and its control method

InactiveCN106862762BEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesSurface finishImpeller

Owner:WUHAN CHUTIAN IND LASER EQUIP

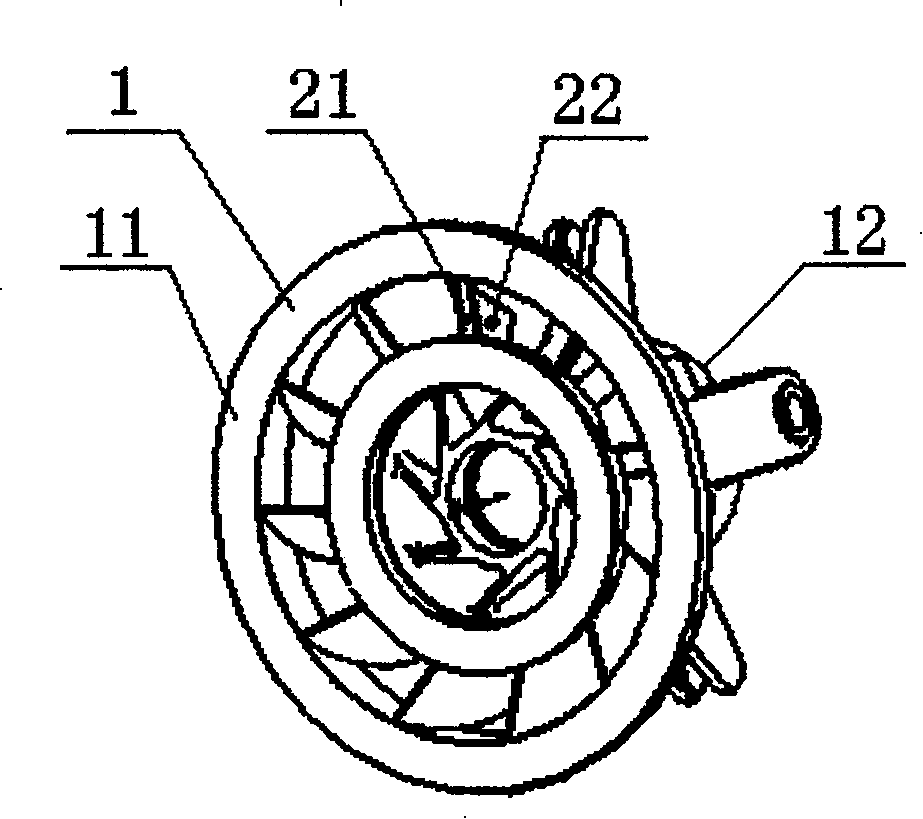

An impeller welding jig with mold groove positioning and auxiliary blanking function and its control method

InactiveCN106862829BEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesSurface finishImpeller

The invention relates to a die cavity locating welding jig with an auxiliary blanking function for an impeller and a control method. The die cavity locating welding jig comprises a base, a central shaft, a compression spring, a top pin and a clamp cover plate; the base is provided with a seam allowance which is matched with another seam allowance in the lower end of the central shaft, the central shaft is mounted on the base, the central shaft is provided with a plurality of die cavities matched with a blade, the upper end of the central shaft is provided with a seam allowance for locating a rear cover plate, the seam allowance in the lower end and the seam allowance in the lower end are coaxial, the top pin is mounted in the base, the compression spring sleeves the top pin, the clamp cover plate is mounted on the base, the top pin is used in a blanking position to push out a workpiece, the compression spring plays a resetting role of the top pin, a semi-finished product of which A surface welding of the impeller has been finished is placed in the die cavity of the central shaft, the upper surface of the base and an impeller semi-finished product are flatly attached, and the rear cover plate is placed in an upper end opening of the central shaft to finish workpiece clamping. The die cavity locating welding jig is simple, easy and fast in clamping and precise in location, reliable in welding quality, high in surface smoothness, high in production efficiency and low in labor intensity and has zero rejection rate.

Owner:WUHAN CHUTIAN IND LASER EQUIP

An anti-welding oxidation rotary welding oil cup fixture and control method

ActiveCN106881549BEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesSpin weldingShielding gas

The invention relates to a spin welding oil cup clamp capable of preventing welding oxidation and a control method. The clamp comprises a hanging basket part, a left clamp part, a right clamp part and shielding gas passages; the left clamp part and the right clamp part are respectively installed at two sides of the hanging basket part; the shielding gas passages are respectively installed in the middle part of the left clamp part and the middle part of the right clamp part; the shielding gas passages are used for blowing protecting gas out when welding to prevent oxidation stain of workpieces during welding and keep the surface of workpieces clean; the oil cup is placed on the clamp; a workpiece is tightly clamped with the left clamp part and the right clamp part at the same time; the hanging basket part rotates and the workpiece rotates along with the turning axle of the hanging basket; through welding heads, welding of multi edges sharing a same cross section is realized; and the left end and the right end can be welded at the same time. Compared with traditional welding devices, the clamping is easy and quick and is accurate in positioning; combined with modern laser welding technology, quick welding is realized; the welding quality is reliable; disability rate is as low as zero; the production efficiency is high and labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

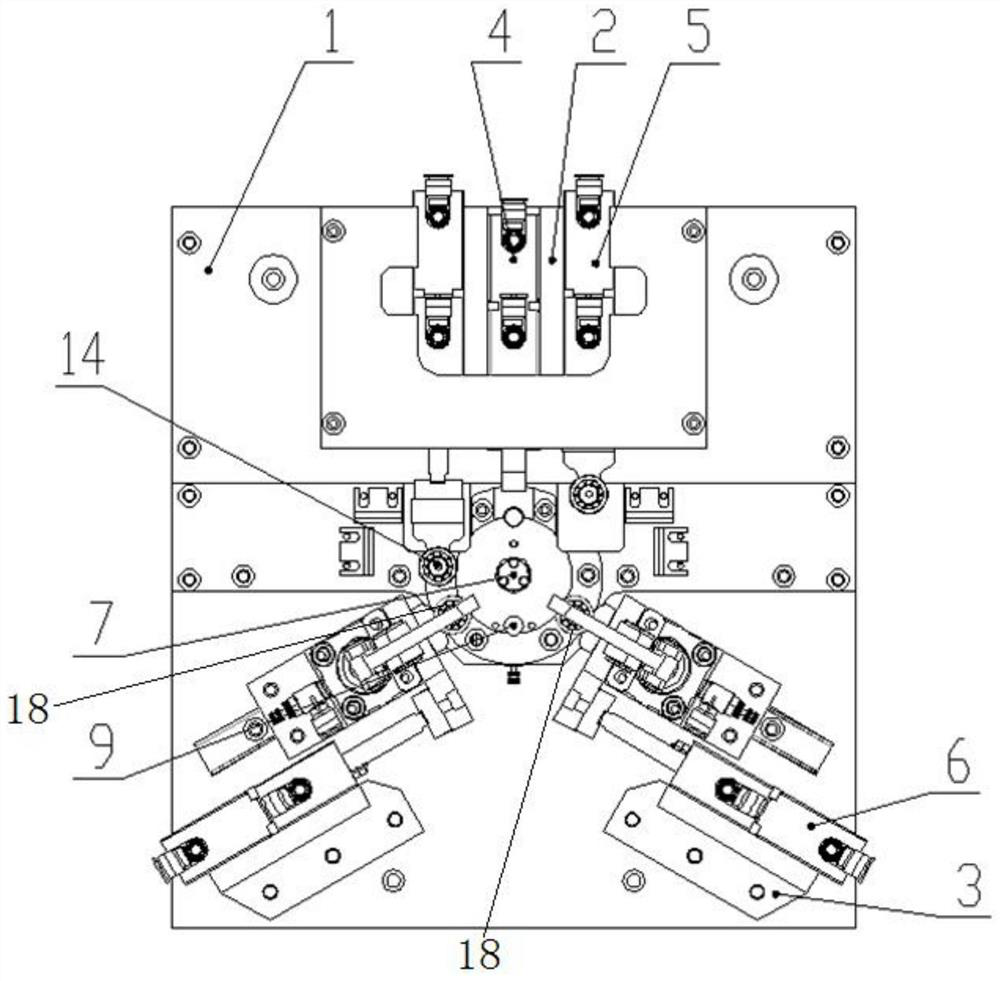

Automatic bending forming and welding fixture for motor stator

ActiveCN112475641AEasy and fast clampingPrecise positioningElectric machinesLaser beam welding apparatusElectric machineryWelding process

The invention relates to an automatic bending forming and welding fixture for a motor stator. Two bending primary forming cylinder mounting plates, two bending secondary forming cylinder mounting plates, a centering module, a positioning module, a height fixing module and a jacking cylinder are respectively fixed on a fixture bracket; two bending primary forming cylinders are installed on the twobending primary forming cylinder mounting plates respectively, two primary forming bending bearings are installed at the front ends of the two bending primary forming cylinders respectively, two bending secondary forming cylinders are installed on the two bending secondary forming cylinder mounting plates respectively, two secondary forming bending bearings are installed at the front ends of the two bending secondary forming cylinders respectively, a toggle clamp air cylinder is installed above a linear guide rail, the centering module is connected with the jacking cylinder through an ejectorpin, and the positioning module and the height fixing module are located at the two sides of the centering module. The automatic bending forming and welding fixture is simple, rapid, accurate in positioning, capable of achieving rapid welding in combination with a laser welding process, high in welding quality, zero in rejection rate, high in production efficiency and low in labor intensity.

Owner:WUHAN ZHONGGU POWER SUPPLY DEVICE

A kind of manufacturing method of drawing mold of aircraft parts of resin-based composite material

ActiveCN105945159BWith self-lubricating functionUniform surface hardnessShaping toolsNumerical controlResin matrix

The invention discloses a manufacturing method for an airplane part stretch-forming mold made of a resin matrix composite and mainly aims to solve the problems that existing molds are large in manufacturing difficulty, hard to store and large in weight and cannot be repaired. The provided manufacturing method for the airplane part stretch-forming mold made of the resin matrix composite comprises the steps that a matrix and a surface are manufactured with the resin matrix composite; and then the airplane part stretch-forming mold is machined and manufactured through a numerical control machine tool. By means of the manufacturing method, the mold using rate is increased, especially, the part productivity is improved, the mold manufacturing cost is reduced, and the mold manufacturing period is shortened.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

Water pump impeller welding fixture

ActiveCN106312338BEasy and fast clampingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlImpeller

The invention relates to a welding clamp of a water pump impeller. The welding clamp comprises a rotating base, a mold seat, a pressing and rotating device, a friction transmission pair, a portal frame, a discharging device and a one-dimensional numerical control workbench. The mold seat is mounted on the rotating base and is coaxial with the rotating base, and the rotating base is mounted on the one-dimensional numerical control workbench. The pressing and rotating device is mounted on the portal frame. One end of the friction transmission pair is mounted on the pressing and rotating device, and the other end of the friction transmission pair is mounted on the mold seat. The discharging device is mounted on the lower portion of the rotating base. The portal frame is mounted above the rotating base in a stretching-over manner. It can be guaranteed that a rotating shaft of the pressing and rotating device and the rotating base are coaxial by adjusting the portal frame and the pressing and rotating device. Compared with a traditional welding device, the welding clamp is simple and fast in clamping and accurate in locating; through combination with the modern laser welding process, fast welding can be achieved; the welding quality is reliable; the zero rejection rate is achieved; the production efficiency is high; and the labor intensity is low.

Owner:WUHAN CHUTIAN IND LASER EQUIP

Anti-deformation restraint device for integral oxidation of silicon microchannel plate substrate

ActiveCN108281338BZero scrap rateNo sintering phenomenonDecorative surface effectsPhoto-emissive cathodes manufactureCircular discEngineering

The invention discloses an Si-microchannel plate base integral oxidation anti-deformation constraint device and belongs to the technical field of photoelectron devices, aiming to overcome the defect of deformation of the Si-microchannel plate base due to oxidation. The anti-deformation constraint device is characterized in that a left guard plate and a right guard plate clamp one retainer ring, the guard plates and the retainer ring are made of sapphire crystals and shaped as circular discs having the same outside diameter, the middles of the guard plates are provided with pores uniformly, theguard plates are 2-3mm in thickness, and the retainer ring is 25-30mm in inside diameter and 350-400 microns in thickness; a plurality of clamp slots are uniformly distributed transversely in a groove-shaped horizontal clamp mount, the width of the clamp slots is greater than the total thickness of the two guard plates and the retainer ring by 20-30 microns; the rims of vertical hold-down barrelsare provided with elongated pores; the horizontal clamp mount and the vertical hold-down barrel are both made of quartz glass; the two guard plates and the retainer ring are positioned in one clamp slot or held down by the upper and lower vertical hold-down barrels, and the rims of the two vertical hold-down barrels are in opposite arrangement. The tolerance of flatness of the Si-microchannel plate is smaller than 10 microns after integral oxidation.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com