Welding clamp of water pump impeller

A technology for welding fixtures and water pump impellers, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve the problems of increasing production costs, reducing production efficiency, and low welding efficiency, achieving zero scrap rate, high production efficiency, and welding Quality and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

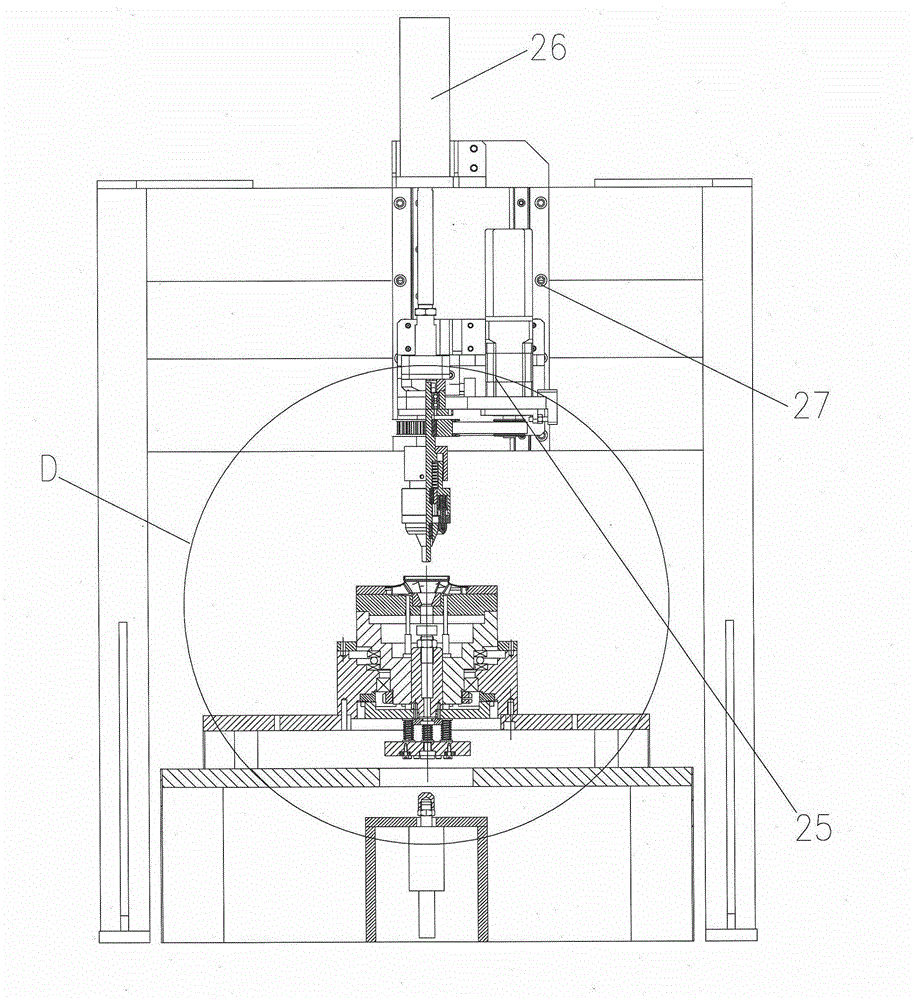

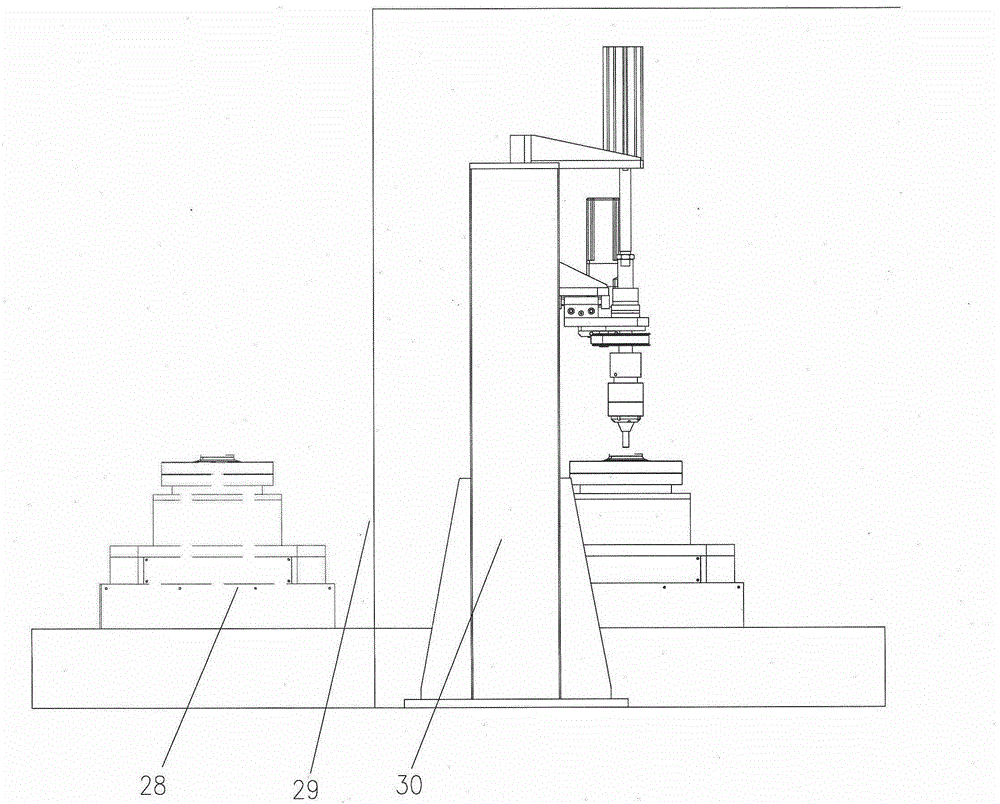

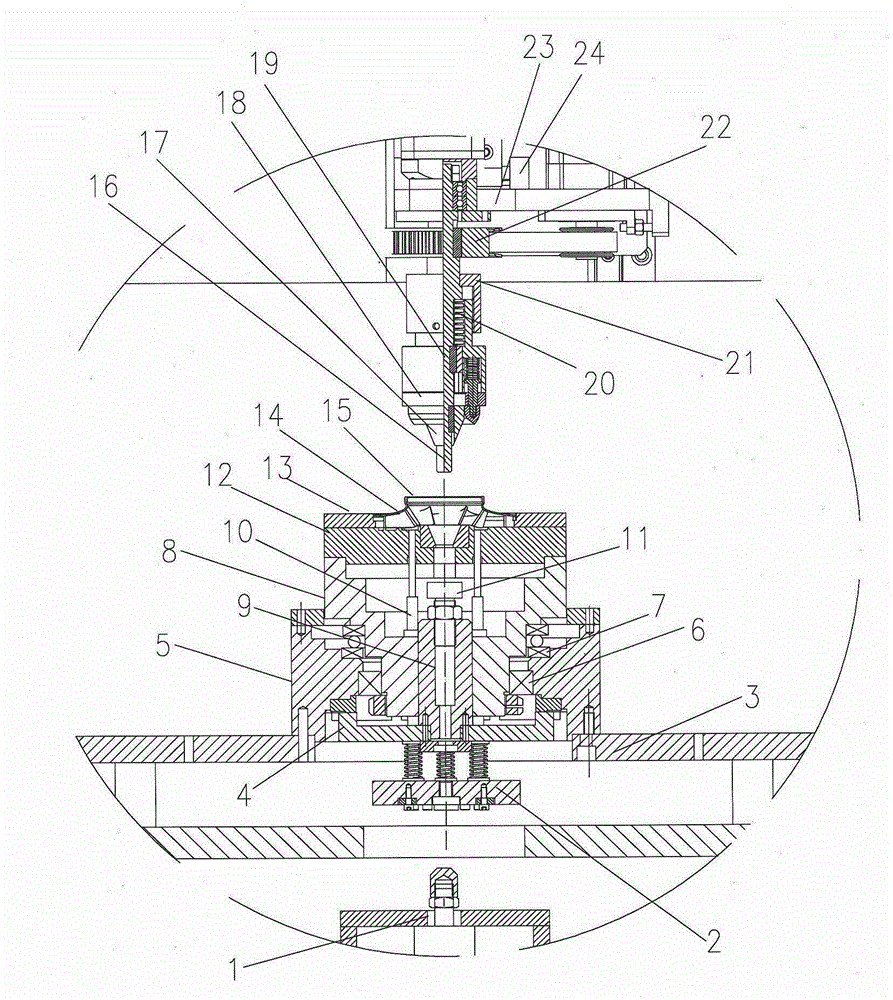

[0021] see Figure 1-Figure 6 , a water pump impeller welding jig related to the present invention is composed of a rotating base, a mold base, a compression rotating device, a friction transmission pair, a gantry frame, a discharge device, and a one-dimensional numerical control workbench group, wherein the mold base is installed on the rotating On the base, the mold base is coaxial with the rotating base, and the rotating base is installed on the one-dimensional numerical control workbench; the pressing and rotating device is installed on the gantry frame, and one end of the friction transmission pair is installed on the rotating and pressing device, and the other end Installed on the mold base, the unloading device is installed under the rotating base, and the gantry is installed across the rotating base. Adjusting the gantry and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com