Anti-deformation restraint device for integral oxidation of silicon microchannel plate substrate

A technology of silicon microchannel plate and restraint device, which is applied in the direction of microstructure device, manufacturing microstructure device, and process for producing decorative surface effects, etc., which can solve the deformation of the silicon microchannel plate substrate and damage the silicon microchannel plate array structure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

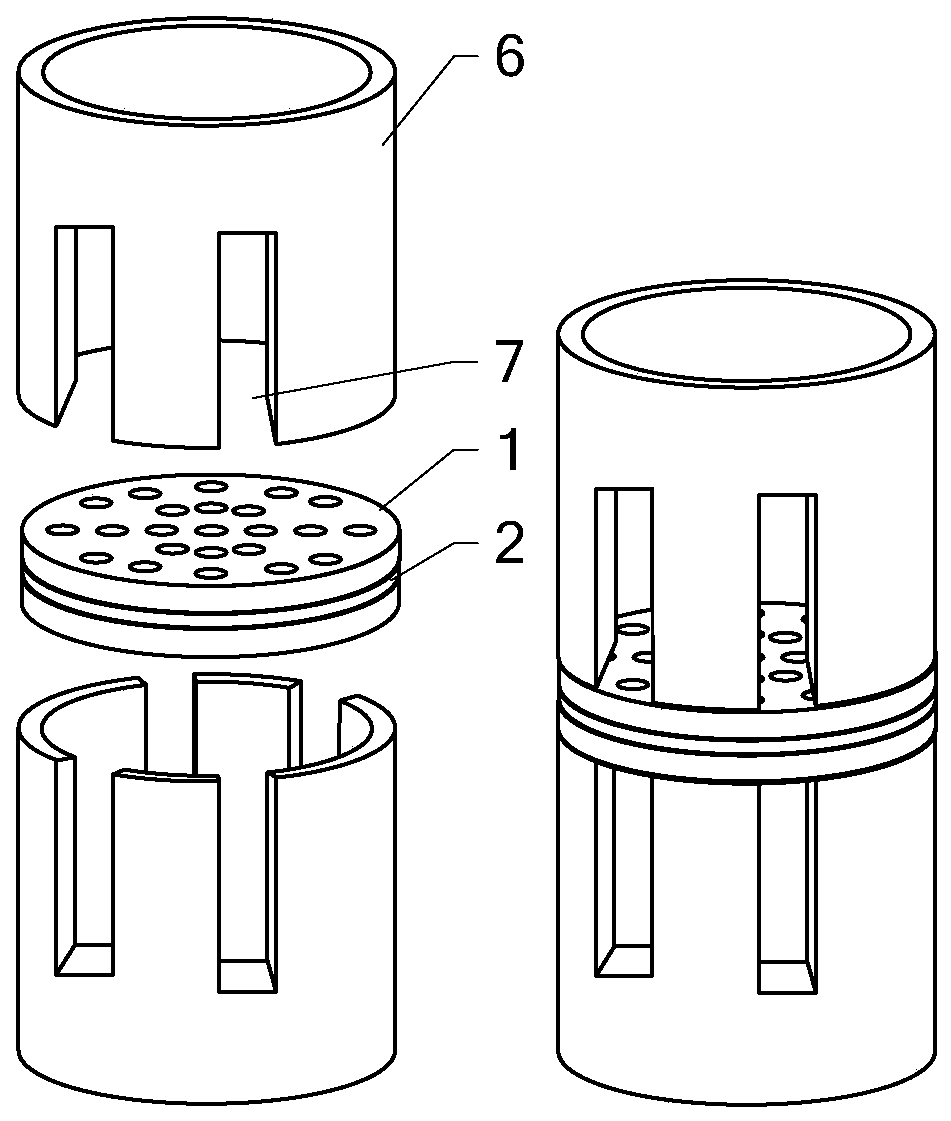

[0010] The specific scheme of the present invention for the whole silicon microchannel plate substrate oxidation prevention deformation restraint device is as follows.

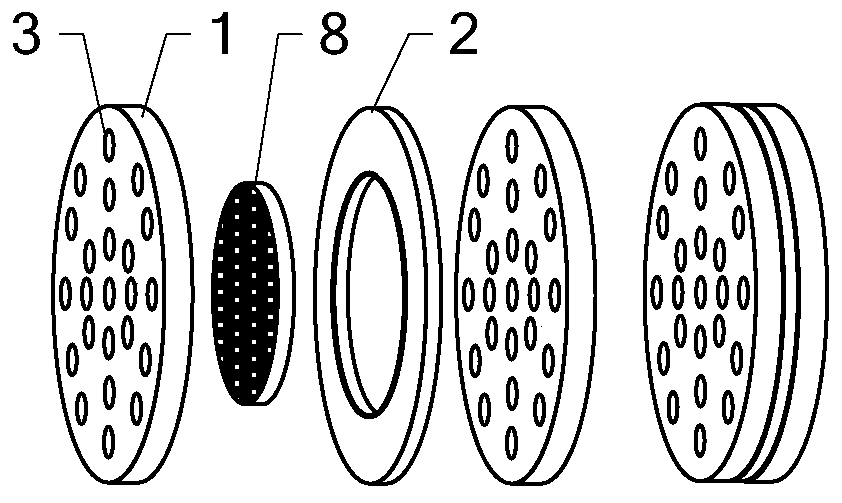

[0011] Such as figure 1 As shown, two guard plates 1 on the left and right clamp a retaining ring 2, guard plate 1 and retaining ring 2 are made of sapphire crystal, guard plate 1 and retaining ring 2 are disc-shaped, and have the same outer diameter, the outer diameter is 50mm. Air holes 3 are evenly distributed in the middle area of the guard plate 1 , the diameter of the middle area distributed with the air holes 3 is 35 mm, and the thickness of the guard plate 1 is 2.3 mm. When the diameter of the microchannel plate 8 to be oxidized is 25 mm and the thickness is 350 μm, the inner diameter of the retaining ring 2 is 30 mm and the thickness is 380 μm.

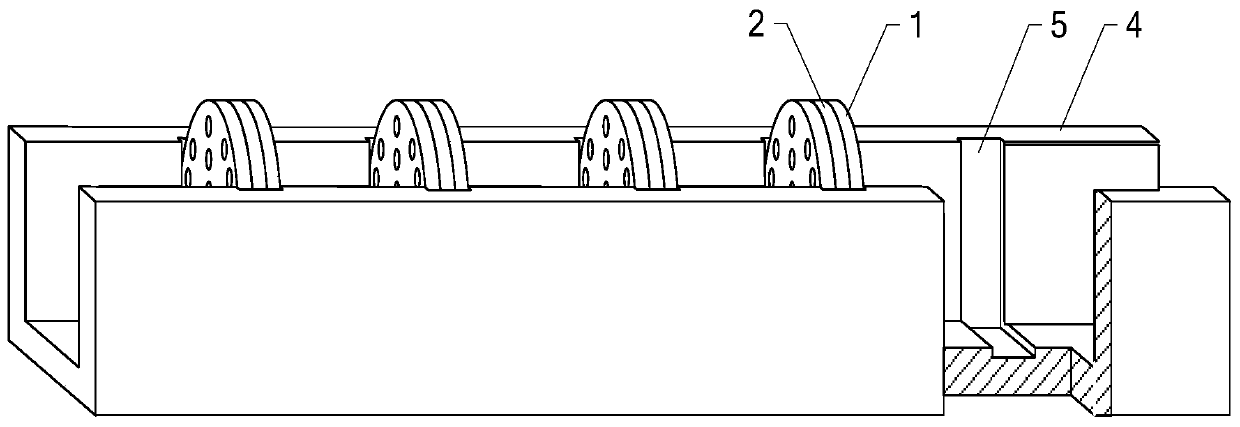

[0012] Such as figure 2 As shown, the horizontal card seat 4 is in the shape of a long groove, and a plurality of card slots 5, such as 5, are distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com