Liquid PTC heating unit whose power is adjusted conveniently

A technology for adjusting power and heating elements, applied in immersion heating devices, ohmic resistance heating parts, etc., can solve problems such as leakage, safety accidents, increase production costs, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It is easy to understand that, according to the technical solution of the present invention, without changing the essence of the present invention, those skilled in the art can imagine various implementations of the liquid PTC heating element for power adjustment of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

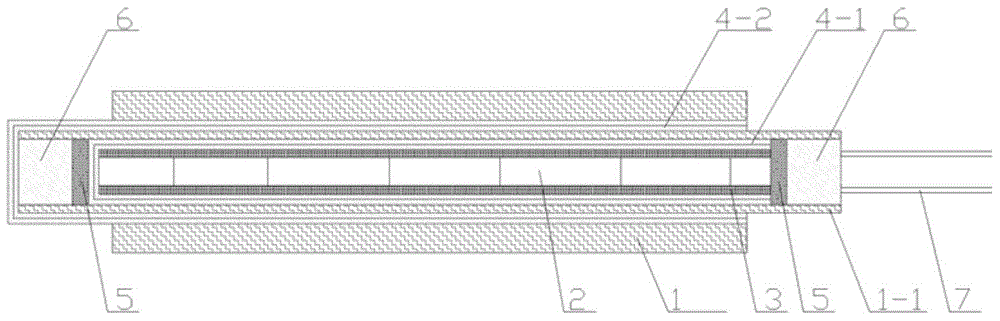

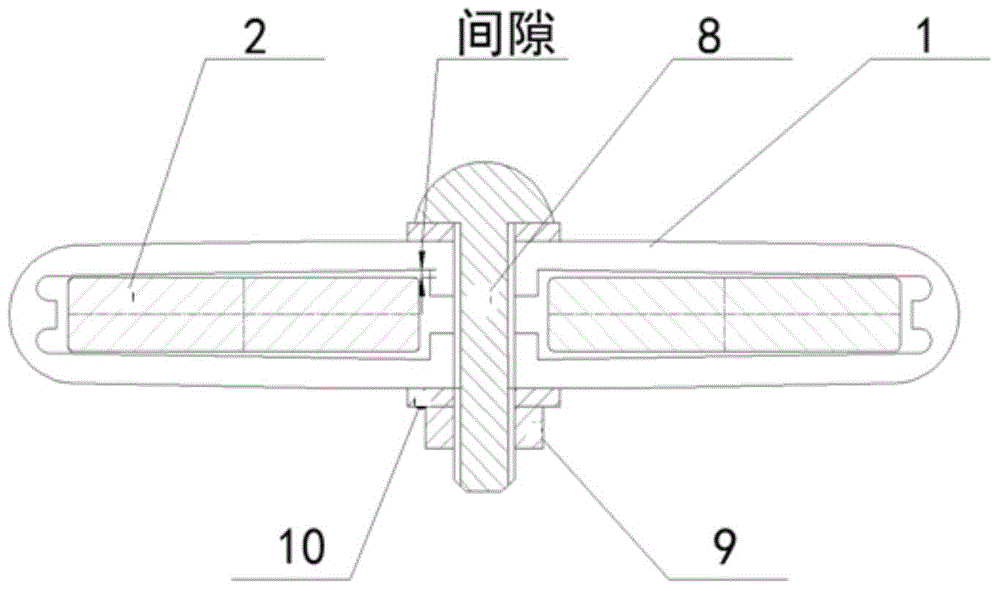

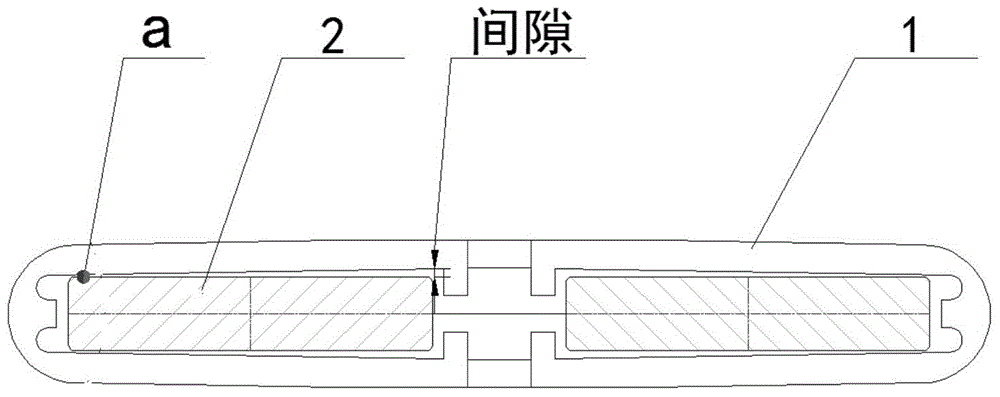

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes two PTC heating chip assemblies, and each PTC heating chip assembly includes several PTC heating chips 2, two layers of insulating layers, and a layer of aluminum shell;

[0022] There is an electrode sheet 3 at the upper and lower ends of each PTC heating sheet, and the electrode sheet 3 can be made of silver, copper, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com