Solar module back veneer comprising non-solvent bonding layers and manufacturing method thereof

A technology for solar cells and adhesive layers, applied in electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as increased manufacturing costs, poor adhesive strength and weather resistance, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

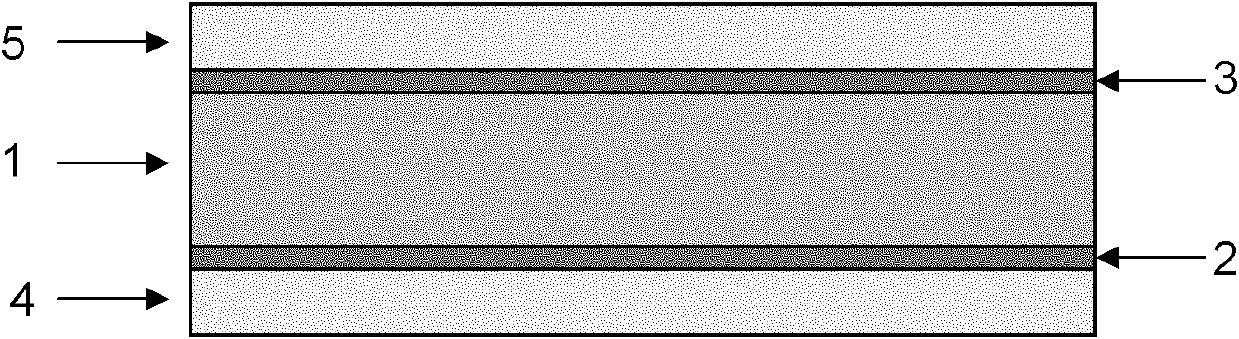

[0077] Using Akema's PVDF film with a thickness of 20 microns; using linear low-density polyethylene LLDPE plastic particles, 1% silane coupling agent, 30% ethylene-butyl acrylate EBA, light stabilizer, and 0.5% anti-aging agent to melt and extrude pellets evenly after mixing, An LLDPE mixture is obtained. Ordinary polymethyl methacrylate PMMA is added with 0.5% light stabilizer and anti-aging agent, and 5% titanium dioxide, mixed uniformly, melted and extruded to granulate. The base film layer adopts common biaxially stretched ethylene terephthalate PET film with a thickness of 200 microns.

[0078] The compounded LLDPE and PMMA are melted and co-extruded onto the biaxially stretched PET film and the middle of the PVDF film through a double-layer extruder, and the extrusion temperature is 280°C, thereby obtaining a four-layer laminate of PVDF / PMMA / LLDPE / PET Membrane, the thickness of the four layers is 20 / 20 / 20 / 200 microns respectively.

[0079] Then on the other side of ...

Embodiment 2

[0087] Using ordinary extrusion-grade polyvinylidene fluoride PVDF plastic particles, adding 5% polymethyl methacrylate PMMA and 5% surface-treated titanium dioxide TiO 2 , Extrude, mix and granulate through a twin-screw extruder at a temperature of about 200°C to obtain PVDF mixture plastic particles. Using linear low density polyethylene LLDPE plastic particles, 1% of silane coupling agent, 30% of ethylene-butyl acrylate EBA, and 0.5% of light stabilizer and anti-aging agent are mechanically mixed in an ordinary mixer to obtain the LLDPE mixture.

[0088] The PVDF mixture and LDPE mixture are melted and co-extruded onto the biaxially stretched PET film through a double-layer extruder, and the extrusion temperature is 280°C, thereby obtaining a PVDF / PE / PET three-layer laminated film, and the thickness of the three layers is respectively 20 / 20 / 200 microns.

[0089] Then on the other side surface of the PET film, extrude the above LDPE mixture and add 5% of surface-treated tit...

Embodiment 3

[0097] Using ordinary extrusion-grade tetrafluoroethylene and hexafluoroethylene copolymer FEP plastic particles, adding 5% of surface-treated titanium dioxide TiO 2 , Extrude, mix and granulate through a twin-screw extruder at a temperature of about 320°C to obtain FEP mixture plastic particles. Low-density polyethylene LDPE plastic particles, 1% silane coupling agent, 30% ethylene-butyl acrylate EBA, and 0.5% light stabilizer and anti-aging agent are mechanically mixed in an ordinary mixer to obtain the LDPE mixture.

[0098] The FEP mixture and the LDPE mixture are melted and co-extruded onto the biaxially stretched PET film through a double-layer extruder, and the extrusion temperature is 300 ° C, thereby obtaining a FEP / PE / PET three-layer laminated film, and the thickness of the three layers is respectively 20 / 20 / 200 microns.

[0099] Then on the other side surface of the PET film, extrude the above LDPE mixture and add 5% of surface-treated titanium dioxide onto the PET...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com