Blowing-filling-sealing multi-row combined mold for plastic ampoule and production method for ampoule by using mold

A combined mold and blow-fill-seal technology, which is applied in pharmaceutical packaging machinery and food fields, can solve problems such as low production efficiency and reduced material utilization, so as to improve production efficiency, improve material utilization, and save polypropylene or polyethylene materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

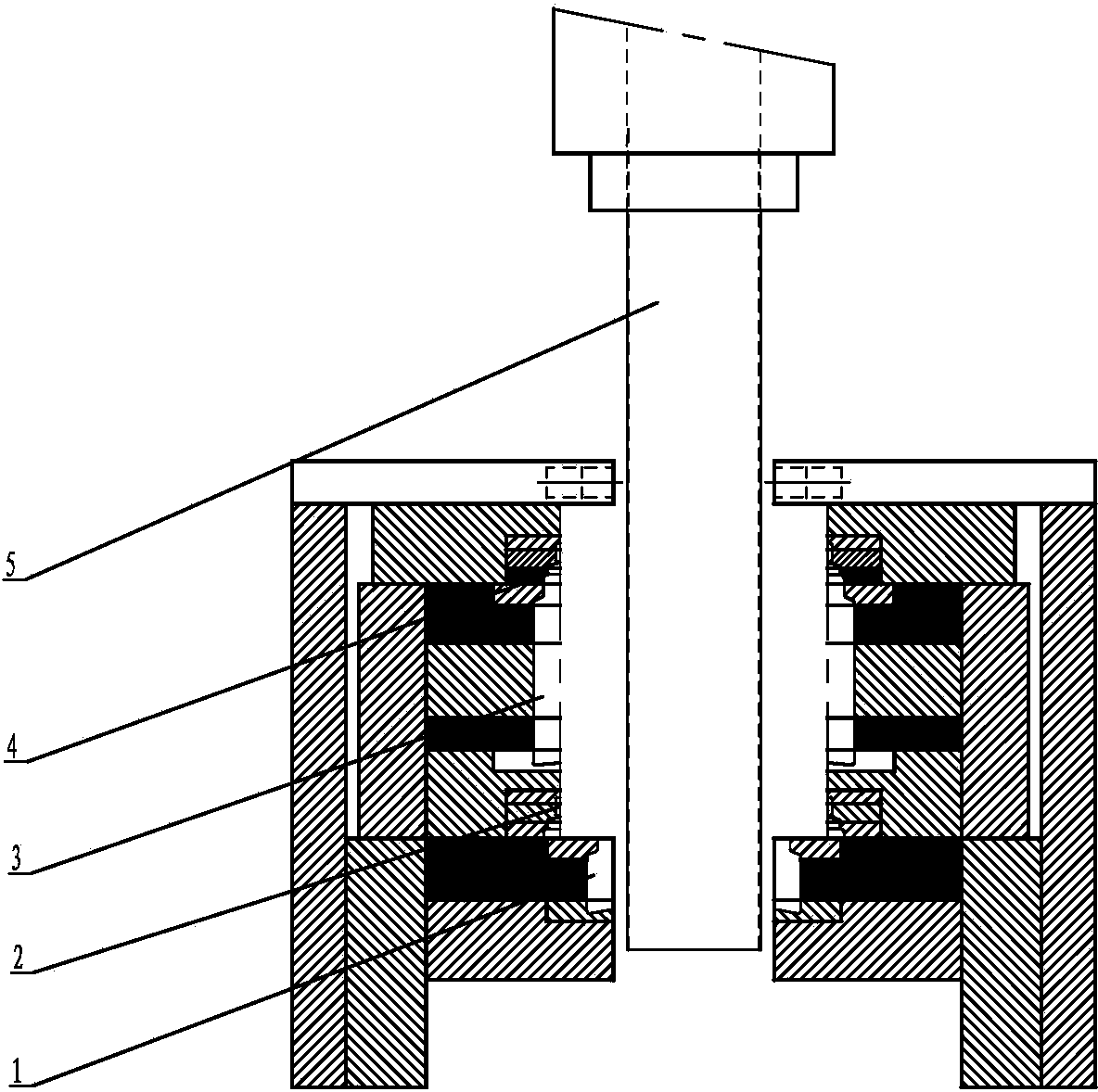

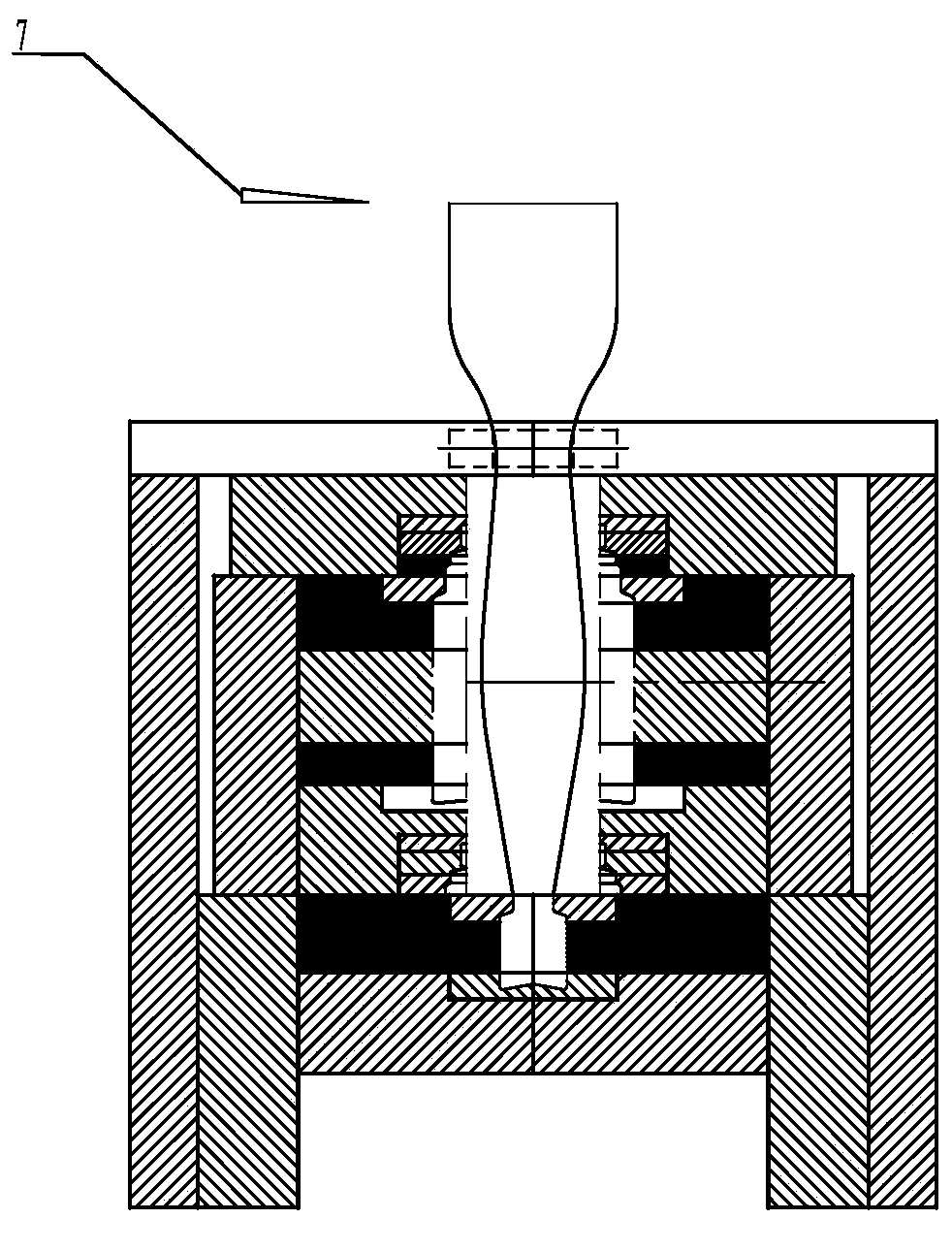

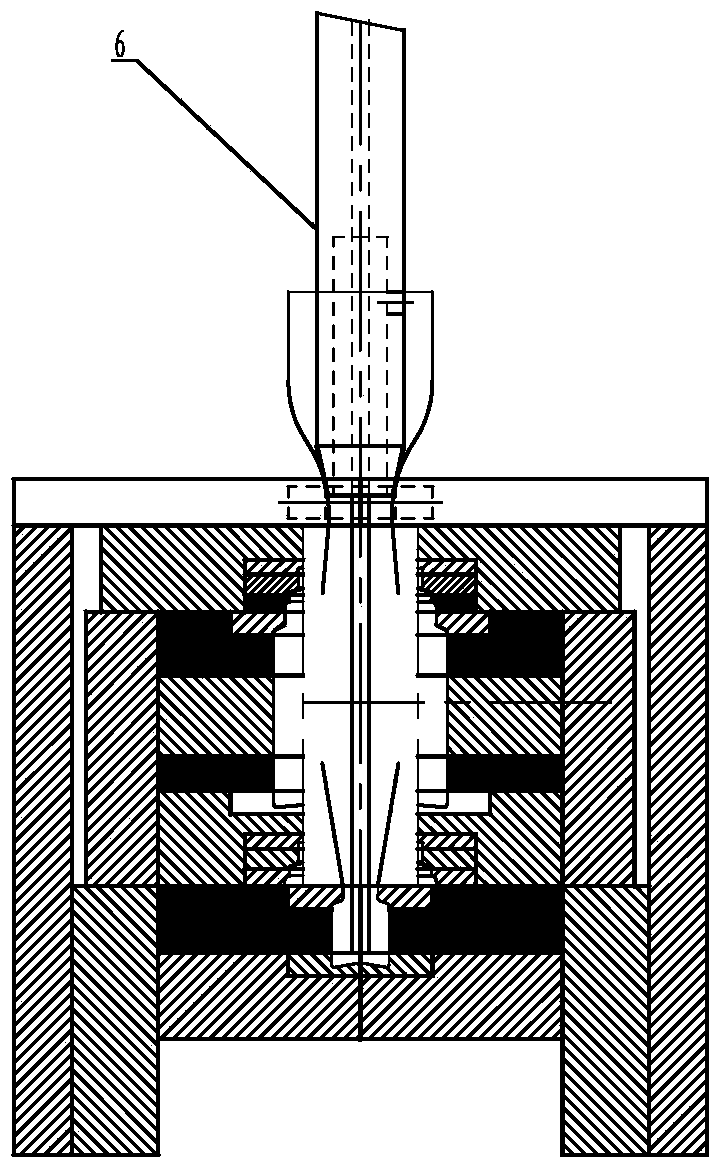

[0032] Such as figure 1 As shown, the plastic ampoule blow-fill-seal multi-row combined mold of the present invention includes a symmetrically arranged left half mold and a right half mold, and the left half mold and the right half mold are sequentially arranged symmetrically from bottom to top. , the lower row of bottle mouth molds 2, the upper row of bottle body molds 3 and the upper row of bottle mouth molds 4, the lower row of bottle mouth molds 2 and the upper row of bottle body molds 3 are fixed together, the lower row of bottle mouth molds 2 and the lower row of bottle bodies Between the molds 1, the upper row of bottle mouth molds 4 and the upper row of bottle body molds 3 are all matched together by slide rails and chutes.

[0033] There is a positioning hole on the left half of the mold, and a positioning pin on the right half of the mold. The positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com